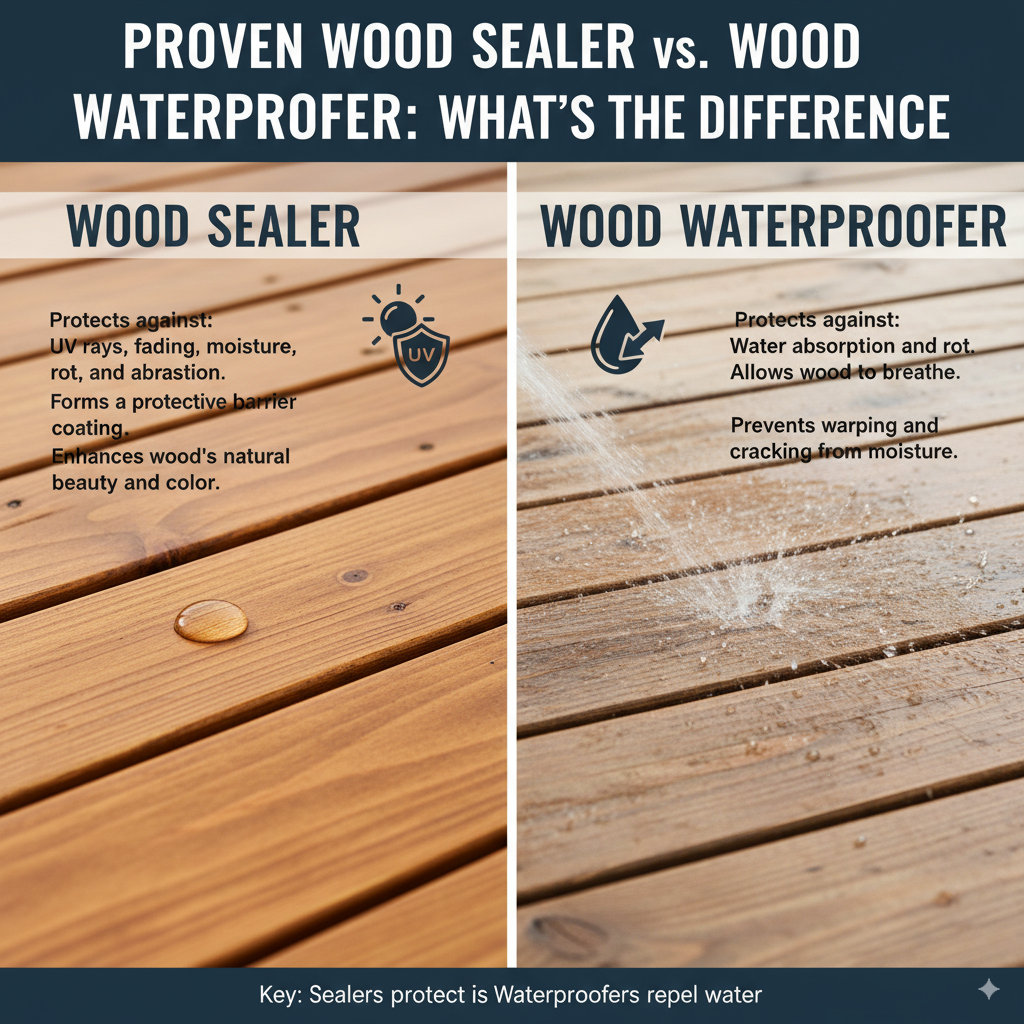

What is the Difference: Proven Wood Sealer vs. Waterproofer

Wood sealer and waterproofer both protect wood, but a sealer generally offers broader protection against moisture, UV rays, and stains, while a waterproofer primarily focuses on repelling liquid water. Understanding their specific functions helps you choose the right product for your project.

Hey there, fellow woodworkers! Ever stood in the aisle, staring at shelves packed with cans and bottles, wondering if you’re grabbing the right stuff to protect your beautiful wooden creations? You’re not alone. Choosing between a wood sealer and a waterproofer can feel like a puzzle, especially when they seem to do similar jobs. But trust me, understanding the subtle, yet important, differences will save you time, frustration, and ensure your projects last for years. We’ll break it down simply, so you can confidently pick the perfect finish for your next build. Let’s get your wood looking great and staying protected!

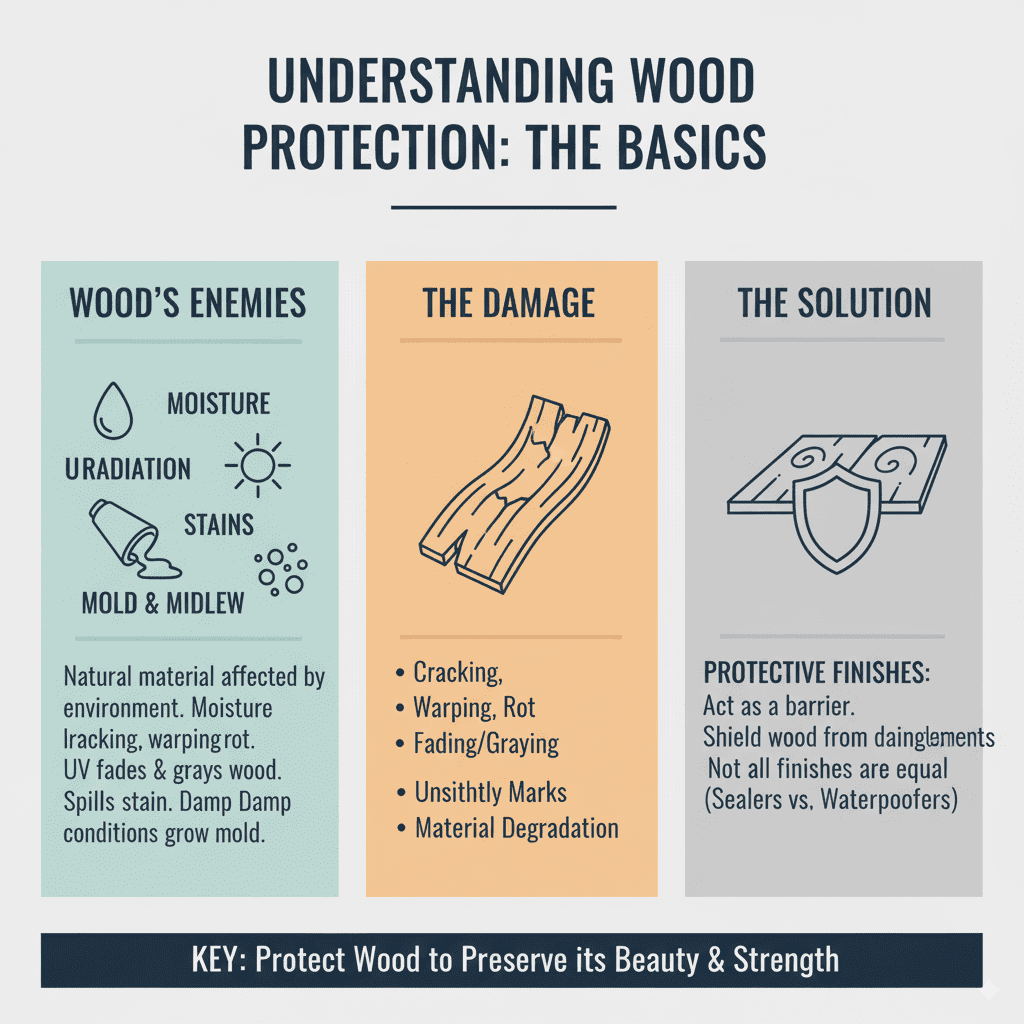

Understanding Wood Protection: The Basics

Wood is a fantastic material – it’s strong, beautiful, and versatile. But it’s also a natural material that can be affected by its environment. Moisture is wood’s biggest enemy. When wood gets wet and then dries out, it can swell and shrink. Over time, this constant expansion and contraction can lead to cracking, warping, and even rot. Beyond just water, wood is also vulnerable to:

UV Radiation: Sunlight can break down the wood’s natural compounds, causing it to fade, turn gray, and become brittle.

Stains: Spills from food, drinks, or other substances can penetrate the wood’s surface, leaving unsightly marks.

Mold and Mildew: Damp conditions can encourage the growth of mold and mildew, which not only look bad but can also degrade the wood.

That’s where protective finishes come in. They act as a barrier, shielding your wood from these damaging elements. But not all finishes are created equal. This is where the distinction between sealers and waterproofers becomes crucial.

What Exactly is a Wood Sealer?

Think of a wood sealer as a comprehensive shield for your wood. Its primary goal is to penetrate the wood’s surface and form a protective layer that seals the pores. This barrier helps to prevent various elements from damaging the wood.

Key Functions of Wood Sealers:

Moisture Control: Sealers significantly reduce how much moisture the wood absorbs. This is vital for preventing swelling, shrinking, and the potential for rot or decay caused by prolonged dampness.

Stain Resistance: By sealing the pores, sealers make it harder for liquids to soak into the wood, making them easier to wipe away before they cause permanent stains.

UV Protection: Many wood sealers contain UV inhibitors that help block the sun’s harmful rays, preventing fading and degradation.

Durability: A good sealer can enhance the wood’s natural beauty and add a layer of toughness against everyday wear and tear.

Types of Wood Sealers:

Wood sealers come in various formulations, each offering slightly different benefits:

Acrylic-based Sealers: These are often water-based, easy to clean up, and provide good UV protection and flexibility. They’re great for exterior projects that might expand and contract.

Oil-based Sealers: These penetrate deeper into the wood, offering excellent water repellency and a rich, natural look. They can be a bit trickier to clean up, though.

Polyurethane Sealers: Known for their toughness and abrasion resistance, polyurethanes are excellent for high-traffic surfaces like tabletops or floors. They can be oil- or water-based.

Varnish Sealers: Similar to polyurethane, varnishes offer a hard, protective finish that’s resistant to moisture and wear.

What Exactly is a Waterproofer?

A waterproofer, as the name suggests, is specifically designed to repel water. Its main job is to prevent liquid water from penetrating the wood’s surface.

Key Functions of Waterproofers:

Water Repellency: This is the core function. Waterproofers create a surface tension that causes water to bead up and roll off, rather than soaking in.

Preventing Water Damage: By stopping water absorption, they help prevent issues like swelling, warping, and the conditions that lead to mold and mildew growth.

Types of Waterproofers:

Waterproofing treatments often fall into a few categories:

Silicone-based Products: These create a water-repellent barrier on the surface. They are very effective at shedding water but may offer less protection against UV rays or stains compared to some sealers.

Wax-based Products: Similar to silicone, these create a barrier that repels water. They can give wood a lovely, natural sheen but may require more frequent reapplication, especially on exterior surfaces.

Penetrating Waterproofers: Some products are designed to soak into the wood fibers, bonding with them to provide water repellency from within. These can be very effective but might not offer the same surface-level stain protection as a film-forming sealer.

The Key Differences: Sealer vs. Waterproofer

While both aim to protect wood, the core difference lies in their scope of protection and how they achieve it.

Scope of Protection:

Sealer: Offers a broader range of protection, typically including moisture resistance, stain blocking, and often UV protection. It seals the wood’s pores to prevent penetration by multiple elements.

Waterproofer: Primarily focuses on repelling liquid water. While this indirectly helps prevent some moisture-related damage, it might not offer significant protection against UV rays or stains unless specifically formulated to do so.

Mechanism of Protection:

Sealer: Works by penetrating the wood and forming a barrier within or on the surface that seals the wood’s pores. This limits the absorption of moisture, stains, and sometimes UV light.

Waterproofer: Primarily works by creating a surface that causes water to bead up and roll off. It doesn’t necessarily “seal” the wood in the same comprehensive way a sealer does, but rather makes the surface non-absorbent to liquids.

Here’s a table that breaks down their typical characteristics:

| Feature | Wood Sealer | Waterproofer |

|---|---|---|

| Primary Function | Seals pores, protects against moisture, stains, UV (often) | Repels liquid water |

| Moisture Protection | High (reduces absorption) | High (repels surface water) |

| Stain Resistance | Generally Good | Variable (depends on formulation) |

| UV Protection | Often Included | Less common, unless specified |

| Penetration | Penetrates and/or forms a surface film | Surface treatment or shallow penetration |

| Breathability | Varies, some are breathable | Varies, can sometimes trap moisture if not breathable |

| Typical Use Cases | Decking, furniture, outdoor structures, interior wood | Outdoor furniture, siding, wood that needs to shed water |

When to Use Which: Making the Right Choice

The best product for your project depends on what you want to achieve and the environment the wood will be in.

Choose a Wood Sealer When:

You need all-around protection: For outdoor projects like decks, fences, or garden furniture that will be exposed to sun, rain, and potential spills, a good sealer is your best bet. It provides a more robust, multi-faceted defense.

You want to prevent staining: If your project is a dining table, a workbench, or anything that might encounter spills, a sealer will offer better stain resistance.

UV protection is important: For wood that will be in direct sunlight for extended periods, a sealer with UV inhibitors will prevent premature fading and graying.

You want a lasting finish: Sealers generally offer longer-lasting protection compared to simple waterproofers.

Example: Protecting a newly built cedar deck. You want it to resist moisture from rain, prevent stains from BBQ grease or drinks, and also hold up against the harsh summer sun. A penetrating acrylic or oil-based deck sealer would be ideal. For more information on deck care, the USDA Forest Products Laboratory offers great resources on wood finishes and their properties.

Choose a Waterproofer When:

Your primary concern is repelling surface water: If you have a wooden garden bench that just needs to shed rain quickly and you don’t anticipate heavy staining or prolonged sun exposure, a dedicated waterproofer might suffice.

You want to maintain the wood’s natural look and feel: Some waterproofers, especially wax or silicone-based ones, can leave a very natural, matte finish without significantly altering the wood’s appearance.

You are applying a finish to something that doesn’t need deep sealing: For instance, some decorative items or woodcrafts where the main goal is simply to make them resistant to light splashes.

Example: Treating wooden garden stakes or decorative birdhouses that are exposed to the elements but don’t require the same level of deep protection as a deck. A silicone-based spray or a wax treatment can be effective.

Application Tips for Both Sealers and Waterproofers

No matter which product you choose, proper application is key to achieving the best results.

Preparation is Paramount:

1. Clean the Wood: Ensure the wood surface is clean, dry, and free from dirt, dust, mold, or old finishes. Use a stiff brush, soap, and water, or a dedicated wood cleaner.

2. Sand if Necessary: If the wood is rough or has old paint/varnish, sand it smooth. Start with a coarser grit (e.g., 80-grit) and move to finer grits (e.g., 120-150 grit) for a smooth finish. Always sand in the direction of the wood grain.

3. Allow to Dry Completely: Wood must be thoroughly dry before applying any finish. For exterior wood, allow at least 24-48 hours of dry weather after cleaning.

Application Process:

Read the Manufacturer’s Instructions: This is the most important step! Every product is different, and the label will tell you the best way to apply it, drying times, and recoating information.

Apply in Favorable Conditions: Avoid applying finishes in direct sunlight, high humidity, or when rain is expected. Ideal temperatures are usually between 50°F and 80°F (10°C and 27°C).

Use the Right Tools: This could be a brush, roller, sprayer, or even a cloth, depending on the product.

Apply Thin, Even Coats: It’s better to apply multiple thin coats than one thick coat. This ensures better penetration and a smoother finish.

Allow Proper Drying Time: Don’t rush. Let each coat dry according to the product’s instructions before applying the next.

Recoat as Needed: Some products require multiple coats for optimal protection.

Pros and Cons at a Glance

To help solidify your decision, here’s a quick rundown of the advantages and disadvantages of each.

Wood Sealers:

Pros:

- Broad protection against moisture, stains, and UV rays.

- Durable and long-lasting.

- Enhances wood’s natural beauty.

- Reduces warping and cracking.

- Available in various finishes (matte, satin, gloss).

Cons:

- Can sometimes alter the wood’s natural color or appearance more than waterproofers.

- Some formulas can be difficult to clean up (e.g., oil-based).

- May require more prep work.

Waterproofers:

Pros:

- Excellent at repelling surface water.

- Often easier and quicker to apply.

- Can leave a very natural, unchanged appearance.

- Some are available in convenient spray cans.

Cons:

- May offer limited protection against stains and UV rays.

- May need more frequent reapplication, especially on high-wear or highly exposed surfaces.

- Some can trap moisture if not breathable, potentially leading to issues.

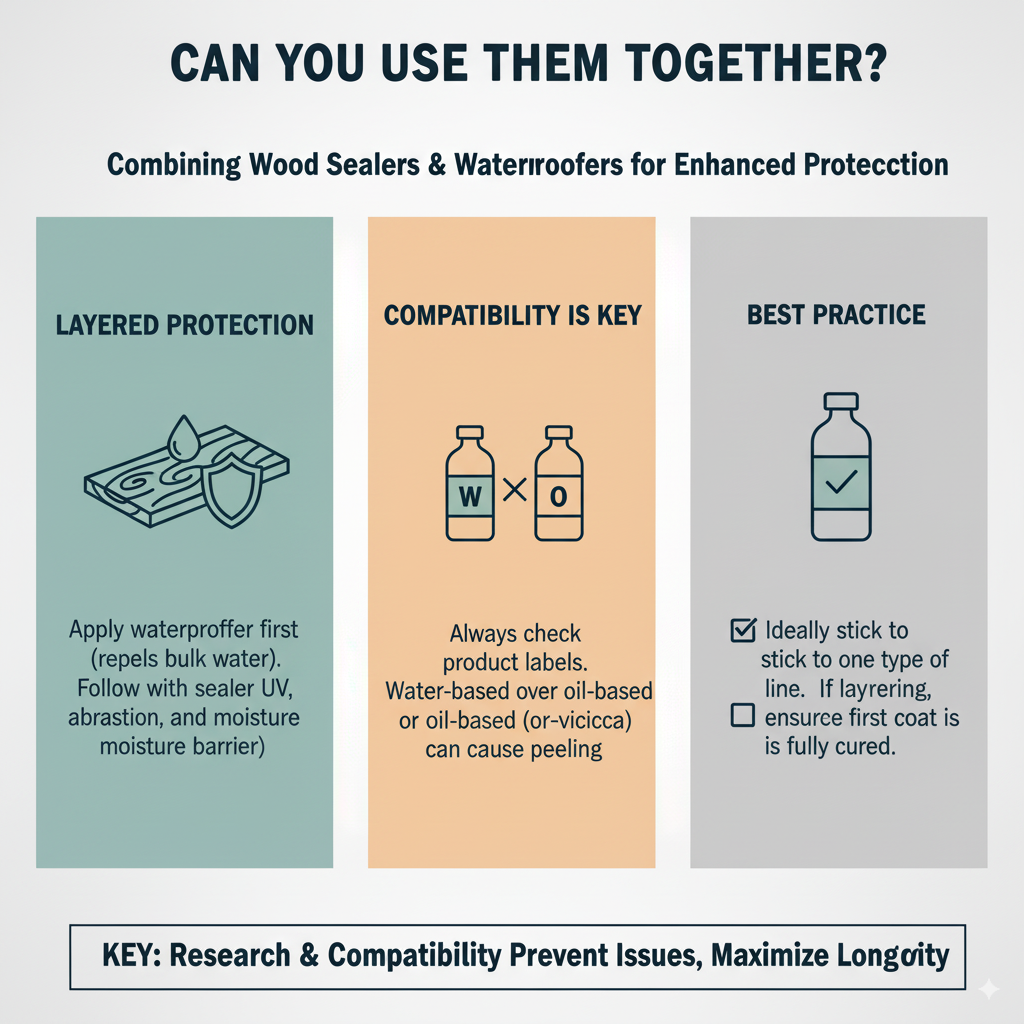

Can You Use Them Together?

In some cases, yes! It’s not uncommon to use a waterproofer as a first line of defense and then follow up with a sealer for added protection. For example, you might use a penetrating waterproofer on a new log cabin wall to repel the bulk of the rain, and then apply a high-quality acrylic sealer with UV protection to further enhance its longevity and appearance.

However, always check the compatibility of the products. Applying a water-based product over an oil-based one (or vice-versa) without proper adhesion or without the first layer being fully cured can lead to peeling or poor performance. It’s often best to stick to one type of finish if possible, or ensure thorough research into product compatibility.

Frequently Asked Questions

Here are some common questions beginners have about wood sealers and waterproofers:

Q1: Will a waterproofer stop my deck from rotting?

A waterproofer will help prevent surface water from soaking into the wood, which is a major contributor to rot. However, it doesn’t typically offer the same deep protection against internal moisture or the biological attack that causes rot as a good quality wood sealer. For long-term deck protection, a dedicated deck sealer is usually recommended.

Q2: Can I use a wood sealer on indoor furniture?

Yes, absolutely! Wood sealers are excellent for indoor furniture. They protect against spills, stains, and general wear and tear, while also enhancing the wood’s natural beauty. Polyurethane and acrylic-based sealers are popular choices for indoor projects.

Q3: How often do I need to reapply wood protection?

This depends heavily on the product used, the type of wood, and the environmental exposure. Exterior projects like decks and fences might need reapplication every 1-3 years, while indoor furniture might last much longer. Always inspect your wood periodically for signs of wear or reduced protection.

Q4: Does sealing wood make it look darker?

Many wood sealers, especially oil-based ones, can deepen the color of the wood, giving it a richer, “wetter” look. Water-based sealers tend to have less of an impact on color, often drying clear. It’s always a good idea to test the product on an inconspicuous area or a scrap piece of the same wood first.

Q5: What’s the difference between a waterproofer and a water repellent*?

In the context of wood finishes, these terms are often used interchangeably. Both aim to make the wood surface shed water. The key is understanding the formulation and its intended level of protection. A “waterproofer” might imply a more robust barrier, while a “water repellent” could be a lighter treatment.

Q6: Can I paint over a wood sealer?

Generally, yes, but it’s crucial to use the right type of paint and ensure the sealer is compatible. For best adhesion, primers are often recommended, especially when painting over oil-based sealers. Water-based paints typically adhere well to water-based sealers. Always check the paint and sealer manufacturer’s guidelines.

Conclusion: Protect Your Projects with Confidence

So there you have it! You’re now equipped with the knowledge to confidently distinguish between wood sealers and waterproofers. Remember, a wood sealer offers a broader spectrum of protection, acting as a comprehensive shield against moisture, stains, and UV rays. A waterproofer, on the other hand, is more specialized, focusing primarily on making the wood surface repel liquid water.

By understanding these differences and considering your project’s specific needs – whether it’s a sunny deck, a busy dining table, or a simple garden accent – you can select the perfect product to safeguard your woodworking creations. Proper preparation and application are your final steps to ensuring a beautiful, long-lasting finish. Now go forth and build with confidence, knowing your projects will be protected for years to come! Happy woodworking!