What To Look For In Engineered Hardwood Flooring

Picking out new floors can feel tricky, especially when you’re new to it. You want something beautiful and lasting, but with engineered hardwood, there are a few more things to think about. It’s easy to get lost in all the choices.

But don’t worry! This guide will break down what to look for in engineered hardwood flooring step-by-step, making it super simple to choose the best option for your home.

Understanding Engineered Hardwood Flooring

Engineered hardwood is a smart choice for many homes because it looks like solid wood but is built differently. This makes it more stable and often more affordable. It’s made of layers, like a sandwich.

The top layer is real hardwood, which is what you see and feel. Beneath that are layers of plywood or high-density fiberboard. This construction helps it handle changes in moisture and temperature better than solid wood.

When you’re looking at options, you’ll see different species of wood for the top layer. Oak, maple, and walnut are popular. The thickness of the top hardwood layer, called the veneer, is very important.

A thicker veneer means you can sand and refinish the floor more times if needed. This adds to its lifespan. The core layers also matter for stability and durability.

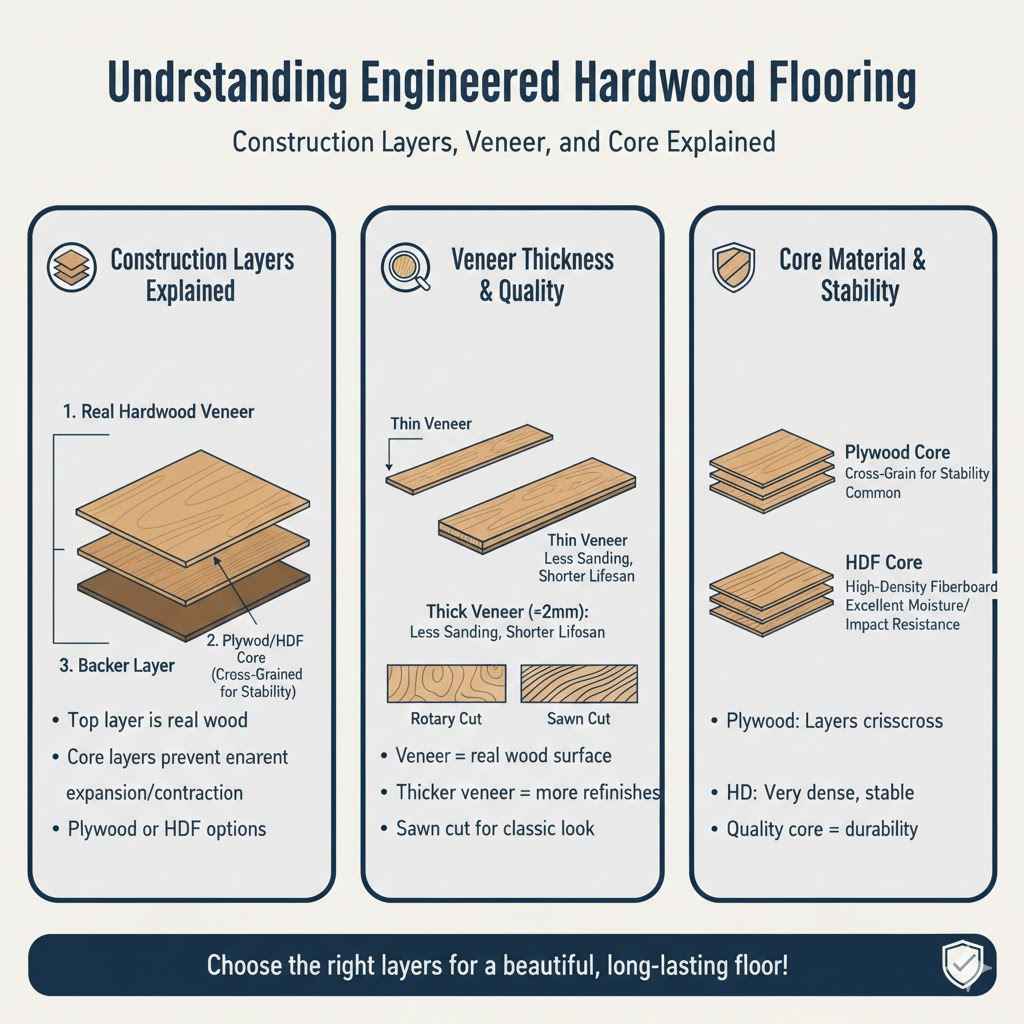

Construction Layers Explained

The way engineered hardwood is built has a big impact on how it performs. It usually has three or more layers. The top layer, the veneer, is the decorative part.

Its thickness can range from a thin 0.5mm to a thicker 4mm or more. A thicker veneer allows for more sanding over the years, giving the floor a longer life. It also means you can repair minor scratches or dents more easily.

The middle layers are typically made from cross-grained plywood. This cross-graining is key to the floor’s stability. It prevents the planks from expanding or contracting too much when humidity or temperature changes.

Some engineered wood uses a core made of high-density fiberboard (HDF). HDF is very dense and stable, offering excellent resistance to moisture and impact. The number and quality of these core layers contribute greatly to the floor’s overall strength and longevity.

Veneer Thickness and Quality

The veneer is the most visible part of your engineered hardwood floor. It’s the real wood surface. Its thickness is a major factor in both appearance and how long the floor will last.

Thin veneers are less expensive but can only be sanded once, if at all. Thicker veneers, often called “wear layers,” allow for multiple sandings and refinishing. This means you can refresh the floor’s look over time.

When choosing, look for engineered hardwood with a wear layer of at least 2mm. For a floor that can be sanded and refinished multiple times, aim for 3mm or more. The quality of the veneer also matters.

Look for consistent grain patterns and good color. Some floors offer “rotary cut” veneers, which can show more swirling patterns. “Sawn cut” veneers often have straighter grain lines and a more classic look.

The milling and finishing of the veneer also affect its appearance and durability.

Core Material and Stability

The core of engineered hardwood flooring is what gives it its strength and stability. Most commonly, this core is made of plywood. The plywood layers are arranged in a cross-grain pattern, meaning the grain of each layer runs perpendicular to the layer below it.

This crisscross structure is what makes the floor resistant to expanding and contracting.

Some engineered wood flooring uses an HDF core. HDF stands for High-Density Fiberboard. This material is made from wood fibers that are compressed together with a resin.

It’s very dense and extremely stable, making it even more resistant to moisture and impact than plywood. Floors with HDF cores are excellent for areas where moisture levels might fluctuate, such as basements or kitchens. The quality of the core material directly affects how well the floor holds up to daily wear and tear.

Key Features to Inspect

When you’re at the store or looking online, there are specific details to check. These details will tell you how good the flooring really is. Think about how the wood is finished, how it’s put together, and even how it feels.

These small things make a big difference in how your floor looks and lasts.

Finishing and Protection

The finish on your engineered hardwood floor is its first line of defense. It protects the wood from scratches, spills, and wear. Most floors use a polyurethane finish.

Some are UV-cured, which makes them very hard and durable. Look for finishes that have aluminum oxide added. This is a very tough material that makes the finish even more resistant to scratches and abrasions.

The finish can also affect the floor’s appearance. Some finishes are matte, which hides dirt and scratches better. Others are semi-gloss or high-gloss, which can make a room feel brighter but show every mark.

You’ll also find different types of stains. Some are oil-based, giving a richer color. Water-based stains are more eco-friendly and dry faster.

Installation Methods

How your engineered hardwood floor is installed is crucial for its performance. Most engineered wood can be installed in a few ways. One common method is the “floating floor” system.

This is where planks are clicked or glued together, and the floor isn’t attached to the subfloor. This method is often easy for DIYers and works well over existing floors.

Another option is “glue-down” installation. Here, the planks are glued directly to the subfloor. This creates a very solid and stable floor.

It’s a great choice for larger areas or in places with a lot of foot traffic. “Nail-down” installation is also possible for some engineered wood products, especially those with thicker veneers. This involves using staples or nails to secure the planks to the subfloor.

The best method often depends on your subfloor type and the specific product you choose.

Edge and End Treatments

The edges and ends of the planks have a big effect on the final look of your floor. Plank edges can be “beveled” or “eased.” A beveled edge has a small, sharp angle. An eased edge is slightly rounded.

Beveled edges create a more distinct shadow line between planks, which can make a floor look more rustic or traditional.

Eased edges create a smoother transition between planks, giving a cleaner, more modern appearance. The ends of the planks also have treatments. Some have micro-beveled edges, which are very fine bevels.

Others have square edges, which create a very flat surface. The type of edge and end treatment you choose will influence the overall aesthetic of your finished floor.

Evaluating Durability and Longevity

When you’re investing in flooring, you want it to last. Engineered hardwood can be very durable, but certain factors make some floors last much longer than others. Thinking about how tough the wood is and how it’s made will help you choose a floor that can handle life’s messes and fun for years.

Abrasion Resistance

Abrasion resistance is how well the floor’s surface stands up to rubbing and scraping. This is mostly determined by the finish. As mentioned, finishes with aluminum oxide are highly resistant to abrasion.

This means they can take a lot of foot traffic without showing wear. Look for ratings or information from the manufacturer about the hardness of the finish.

A floor with good abrasion resistance will resist scuffs and scratches from pets, furniture, and everyday activities. This is especially important in busy households. Even the hardest woods can be damaged by abrasive grit, so keeping floors clean helps a lot.

The quality of the finish is truly the key to resisting these daily wear and tear marks.

Impact Resistance

Impact resistance refers to how well the floor can handle being hit or having things dropped on it. The core material plays a big role here. A denser core, like HDF, provides better impact resistance than softer core materials.

The thickness of the veneer also matters; a thicker veneer might absorb some of the impact better than a very thin one.

While engineered hardwood is generally more stable, heavy impacts can still cause damage. Things like dropping a heavy pot in the kitchen or a toy can leave dents. Choosing a floor with a good quality core and a decent veneer thickness will help minimize the risk of such damage.

Regular maintenance, like using rugs in high-traffic areas or placing felt pads under furniture, also helps protect the floor.

Moisture Resistance

One of the biggest advantages of engineered hardwood over solid hardwood is its better resistance to moisture. The layered construction with cross-grained core helps prevent warping and cupping caused by changes in humidity. However, it’s important to remember that it is still wood, and prolonged exposure to standing water can cause damage.

Floors with HDF cores tend to have even better moisture resistance than those with plywood cores. When choosing for areas like kitchens, bathrooms, or basements, look for products specifically advertised as moisture-resistant. Proper sealing and maintenance are also important for maximizing moisture resistance.

Cleaning up spills quickly is always a good practice to prevent any damage.

Janka Hardness Rating

The Janka hardness test measures the resistance of wood species to denting and wear. It works by measuring the force needed to embed a steel ball halfway into a piece of wood. A higher Janka rating means the wood is harder and more resistant to dents.

For example, red oak typically has a Janka rating of around 1290, while maple is around 1450. Exotic woods like Brazilian walnut can have ratings over 3000. When considering engineered hardwood, the Janka rating applies to the top veneer layer.

A higher rating for the species means the hardwood surface itself will be more durable against impacts. However, remember that the core and finish also contribute to the overall durability.

Design and Aesthetic Considerations

Flooring is a major design element in any room. The look of your engineered hardwood floor can completely change the feel of your home. From the color and grain to the width of the planks, these choices matter for style and how the room feels.

Wood Species and Color

The species of wood used for the top veneer greatly influences the floor’s appearance. Oak is a popular choice because of its attractive grain patterns and durability. It comes in various shades, from light natural oak to darker stained finishes.

Maple offers a smoother, more uniform grain and a lighter color, giving a clean, modern look.

Walnut is prized for its rich, dark color and beautiful, natural grain. Other species like hickory, ash, and cherry also offer unique looks. When selecting a color, think about the existing decor in your home.

Light colors can make a room feel larger and brighter, while darker colors can create a more intimate and luxurious atmosphere. The stain also plays a huge role, so consider how it interacts with the wood’s natural tones.

Plank Width and Length

The width of the engineered hardwood planks can dramatically change the visual impact of a room. Wider planks (5 inches and up) tend to create a more contemporary and spacious feel. They can make a room look larger and less busy, as there are fewer seams.

This is often a popular choice for open-plan living areas.

Narrower planks (2 to 4 inches) can give a more traditional or classic look. They can make a room feel cozier. If you have a smaller room, very wide planks might overwhelm the space.

Conversely, very narrow planks in a large room might look too busy. Plank length also matters. Longer planks generally contribute to a more expansive feel, while shorter planks can create a sense of movement or pattern.

Surface Textures and Finishes

Beyond color, the surface texture and finish of engineered hardwood can add a lot of character. You can find smooth, hand-scraped, or wire-brushed finishes. A smooth finish is classic and simple.

Hand-scraped finishes have slight undulations and variations that mimic the look of floors that were traditionally scraped by hand.

Wire-brushed finishes use a wire brush to lift the softer wood grain, creating a textured surface. This texture can hide minor imperfections and add a rustic or casual feel. The sheen of the finish also affects the look.

Matte finishes are subtle and hide wear well. Satin finishes offer a soft glow, while glossy finishes are high-shine and can make a room feel more formal. The combination of texture and sheen can significantly impact the overall style.

Comparing Engineered Hardwood Options

When you’re choosing engineered hardwood, it’s helpful to compare different types. Not all engineered wood is made the same. Understanding the differences can help you pick the best fit for your budget and needs.

| Feature | Good Quality Option | Budget Option |

|---|---|---|

| Veneer Thickness | 3mm+ | 1mm-2mm |

| Core Material | Multi-ply plywood or HDF | Fewer plywood layers, potentially lower density |

| Finish | Aluminum Oxide, multiple coats | Standard polyurethane, fewer coats |

| Installation | Versatile (floating, glue-down, nail-down) | Often limited to floating |

| Price | $$$ | $ |

A good quality engineered hardwood will have a thicker veneer that allows for refinishing. Its core will be stable and dense, providing excellent durability. The finish will be robust, offering great protection against daily wear and tear.

These floors might cost more upfront, but their longevity and ability to be refreshed make them a sound investment over time.

Budget-friendly options often have thinner veneers. This means they cannot be sanded or refinished. The core material might be less dense, making them more prone to dents and scratches.

The finish may also be less durable. While these floors can look good initially, they may not hold up as well to heavy use and might need

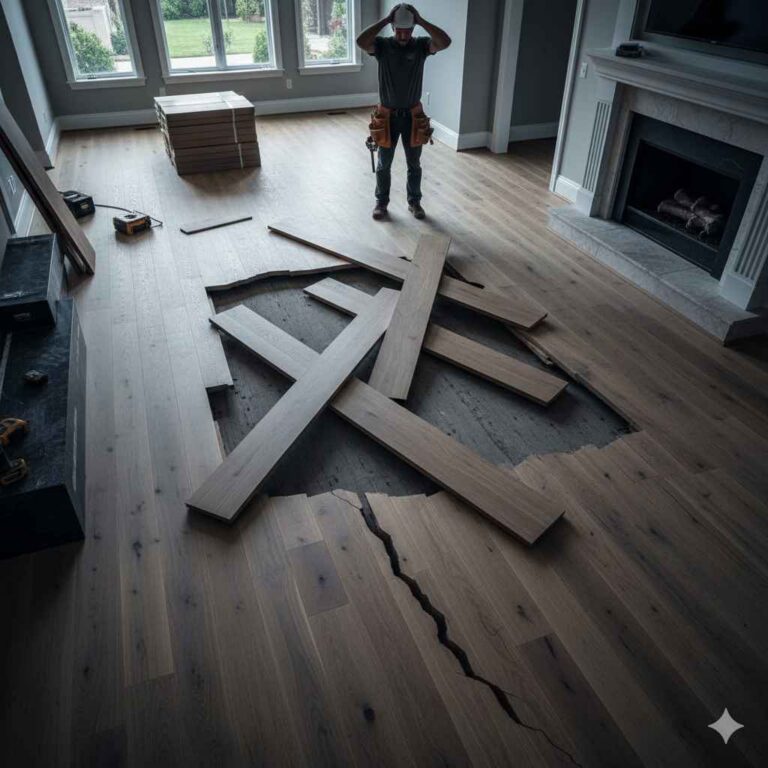

Real-Life Examples

Consider Sarah, who was renovating her busy family home. She chose engineered oak flooring with a 3mm veneer and a hard-wearing aluminum oxide finish. The planks were 7 inches wide, giving her living room a modern feel.

Even with two energetic kids and a dog, the floors held up well. After five years, a few minor scratches appeared, but they were barely noticeable thanks to the textured finish. She found that the stability of the engineered wood was also great, as her basement area, where she installed it, experienced some humidity changes without issue.

Mark, on the other hand, was looking for a budget-friendly option for his rental property. He opted for engineered bamboo with a thin veneer and a standard finish. The installation was quick and easy using the click-lock system.

The floors looked attractive and made the apartment feel updated. However, after a couple of years, the finish started to show wear, especially in high-traffic areas near the entryway. He knew these floors wouldn’t last as long as a premium option, but they served their purpose for the rental.

Sample Scenarios

-

Scenario: You have young children and pets and want a floor that can withstand spills and playtime.

Consideration: Look for engineered hardwood with a thick wear layer (3mm+) and a durable, scratch-resistant finish like one with aluminum oxide. HDF core options will also offer better impact resistance. -

Scenario: You are installing flooring in a basement where moisture can be a concern.

Consideration: Prioritize engineered hardwood with an HDF core, as it offers superior moisture resistance. Ensure proper sealing of the subfloor and prompt cleanup of any spills. -

Scenario: You want a classic, timeless look for your formal dining room.

Consideration: Choose a species like red oak or walnut with a medium to dark stain and a smooth or slightly eased edge treatment. Plank width can be adjusted to your preference, but narrower planks might enhance the traditional feel.

Maintenance and Care

Keeping your engineered hardwood floor looking its best is simple with the right care. Regular cleaning and a few smart habits will help it last for many years. It’s not difficult, and it makes a big difference in how your floor looks and ages.

Daily Cleaning Routine

For daily cleaning, a soft-bristle broom or a vacuum cleaner with a hard floor attachment is ideal. Avoid using vacuums with beater bars, as they can scratch the surface. The goal is to remove dust, dirt, and grit that can act like sandpaper over time.

If you have pets, this step is especially important to manage shedding and track-in dirt.

For most spills or sticky spots, a slightly damp mop can be used. It’s very important that the mop is only damp, not wet. You should never let water pool on the floor.

After mopping, dry the area with a clean towel. This quick and simple routine prevents dirt buildup and keeps your floor looking fresh.

Deep Cleaning and Protecting

Occasionally, you might need to do a deeper clean. Use a pH-neutral wood floor cleaner. Always follow the manufacturer’s instructions for the specific cleaner you are using.

Never use harsh chemicals, abrasive cleaners, or steam mops, as these can damage the finish and the wood itself. Steam can penetrate the wood and cause swelling or warping.

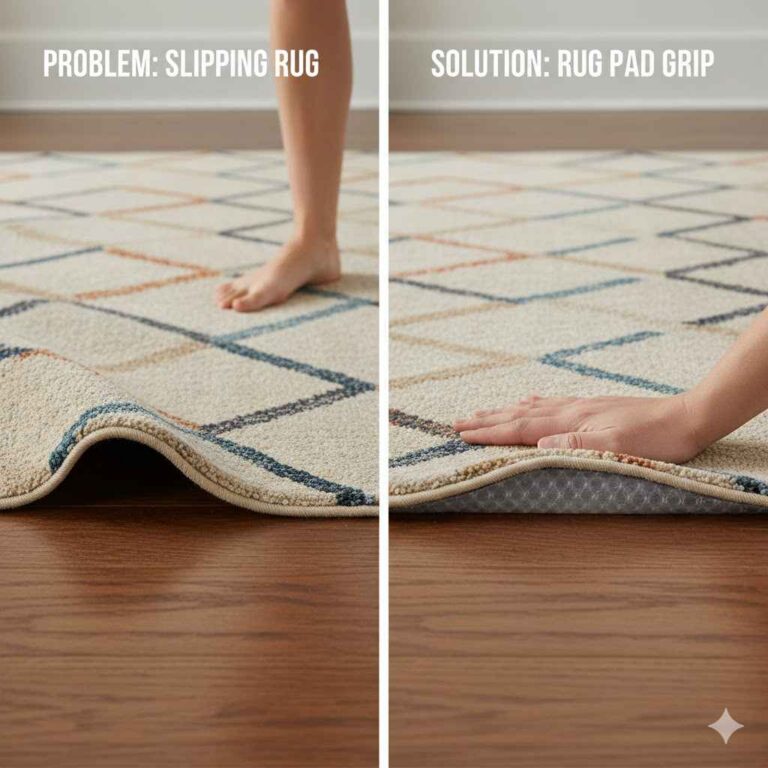

To protect your floor from dents and scratches, use felt pads on the legs of all furniture. Avoid dragging chairs or tables; lift them instead. For areas with heavy foot traffic, consider using area rugs.

This is especially useful at entryways to catch dirt and moisture. Taking these protective measures will significantly extend the life and beauty of your engineered hardwood flooring.

Dealing with Scratches and Dents

If minor scratches appear, they can often be buffed out with a wood floor polish designed for your floor’s finish. For deeper scratches on floors with a thick veneer, you might be able to sand and refinish the affected area or the entire floor. This is a significant advantage of engineered hardwood over laminate or vinyl flooring.

For dents, if the veneer is thick enough, a professional refinisher might be able to repair them. However, prevention is key. Using furniture pads and rugs is the best way to avoid dents in the first place.

If a dent is significant and cannot be repaired, replacing the damaged plank might be an option, though this can be complex depending on the installation method.

Frequently Asked Questions

Question: What is the most important factor when choosing engineered hardwood flooring?

Answer: The thickness of the top hardwood veneer is very important. A thicker veneer means you can sand and refinish the floor more times, extending its life.

Question: Can engineered hardwood flooring be used in kitchens?

Answer: Yes, engineered hardwood can be used in kitchens, especially those with HDF cores, due to their improved moisture resistance. However, always clean up spills immediately.

Question: How often should I clean my engineered hardwood floors?

Answer: You should sweep or vacuum your floors daily or every other day to remove dirt and grit. Damp mop as needed for spills or deeper cleaning.

Question: Will my engineered hardwood floor scratch easily?

Answer: It depends on the wood species, veneer thickness, and the quality of the finish. Floors with aluminum oxide finishes and harder wood species are more scratch-resistant.

Question: Can I install engineered hardwood myself?

Answer: Many engineered hardwood floors are designed for DIY installation using a floating method. However, if you are not comfortable with DIY projects, professional installation is recommended.

Wrap Up

Choosing engineered hardwood floors involves looking at the veneer thickness, core stability, and finish quality. Consider the wood species, plank size, and edge details to match your style. Proper installation and consistent maintenance are key for durability.

By focusing on these points, you will find a beautiful and lasting floor.