Can You Use Tractor Hydraulic Fluid In Wood Splitters? Proven Best

Yes, you can often use the correct type of tractor hydraulic fluid (like AW 30 or ISO 32/46) in many wood splitters, provided the viscosity and specifications meet the machine’s manual requirements. Always check your wood splitter’s owner’s manual first to ensure compatibility and prevent pump damage.

Are you staring at an empty hydraulic reservoir on your wood splitter, staring at a fresh jug of tractor hydraulic fluid, and wondering if you can just top it off? It’s a common spot to be in! Mixing up fluids or using the wrong type can seriously harm the pump—that’s the heart of your splitter. Don’t worry; we’ve all been there, wanting a quick fix without risking an expensive repair.

This guide will clear up the confusion about using common tractor hydraulic fluid (often called AW or Universal Tractor Fluid) in your wood splitter. We’ll break down the specs, show you how to check your machine, and give you the confidence to choose the right liquid for the job. Let’s make sure your splitter stays strong and ready for the next big log!

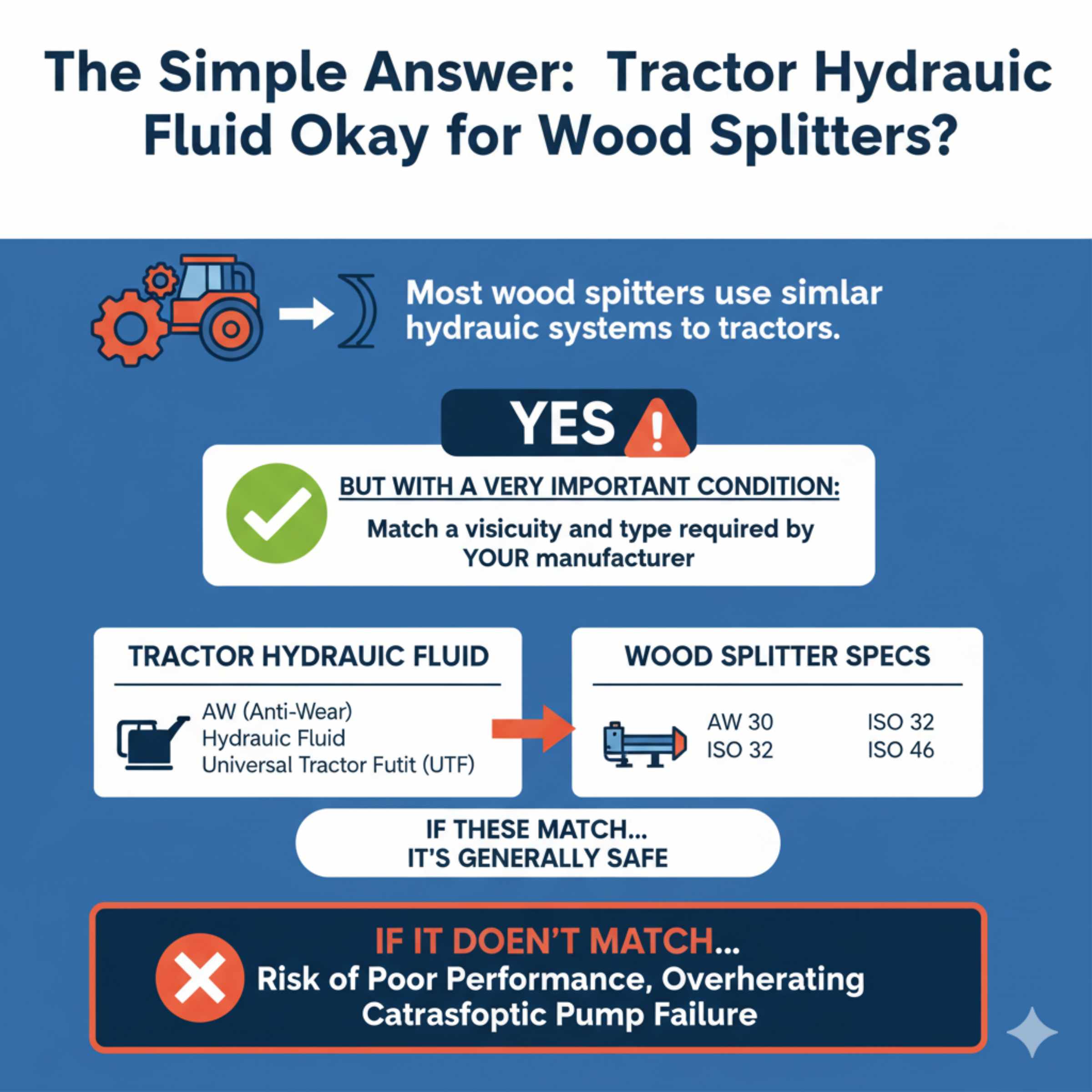

The Simple Answer: Is Tractor Hydraulic Fluid Okay for Wood Splitters?

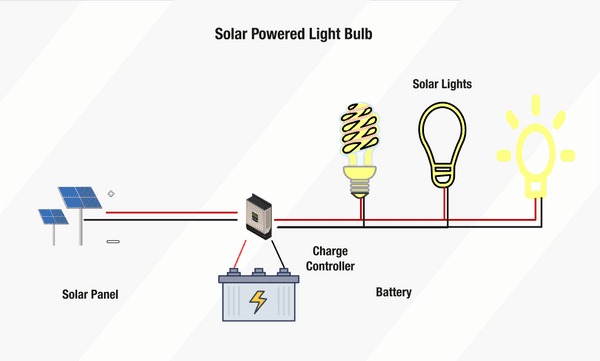

When it comes to the heart of your hydraulic system, clarity is key. Most wood splitters use a hydraulic system very similar to the hydraulics found on tractors, log splitters, and small construction equipment. Because of this similarity, there is often overlap in the recommended fluids.

The short answer is yes, often you can, but with a very important condition: you must match the viscosity and type required by your specific wood splitter manufacturer.

Tractor hydraulic fluid is usually categorized as AW (Anti-Wear) hydraulic fluid or sometimes as Universal Tractor Fluid (UTF). Wood splitters commonly specify AW 30, ISO 32, or ISO 46. If the tractor fluid matches these specs, it is generally safe to use. If it doesn’t match, you risk poor performance, overheating, and potentially catastrophic pump failure.

Understanding the Jargon: What Makes Hydraulic Fluid ‘Right’?

Before we start pouring, we need to understand the three main things that matter in hydraulic fluid. Think of these as the three rules for fluid compatibility:

- Viscosity (Thickness): This is the most critical factor. It describes how thick or thin the fluid is at operating temperature. Too thin, and it won’t lubricate properly; too thick, and the pump struggles to move it, causing strain.

- Additives (AW Rating): Modern hydraulic systems, especially those with gear pumps like most splitters use, need Anti-Wear (AW) additives. These prevent metal parts from grinding against each other under high pressure. Most tractor fluids are AW rated.

- Temperature Range: The fluid needs to work well whether it’s a cool morning in the fall or a warmer day in the spring. Viscosity ratings help define this.

Step 1: Consult Your Wood Splitter’s Owner’s Manual (The Golden Rule)

I know, I know—the manual is often hiding under a pile of greasy rags. But this step is non-negotiable for a confident, long-lasting repair. Think of the manual as the manufacturer telling you exactly what your pump needs to survive.

Why Checking the Manual Beats Guessing

Manufacturers spend a lot of time testing their pumps. They specify a fluid for a reason. Using the wrong fluid is like putting regular gasoline in a diesel engine—it might run for a bit, but it will cause serious, expensive damage over time.

What you are looking for in the manual will usually be listed under “Specifications,” “Hydraulic Fluid Type,” or “Recommended Lubricants.”

Common Fluid Designations You Might See:

- ISO Grade: This is the International Organization for Standardization measurement for viscosity. Common numbers are ISO 32 or ISO 46.

- SAE Grade: This is often listed as SAE 10W, SAE 20W, or most commonly for splitters, SAE 30 (which often corresponds closely to ISO 68, but always defer to the ISO/AW rating if both are listed).

- AW Rating: Look for AW (Anti-Wear) designation.

If your manual calls for ISO 32, you need to find a hydraulic fluid that is ISO 32, whether it’s specifically labeled “Hydraulic Oil” or “Tractor Fluid.”

Step 2: Matching Tractor Fluid Types to Wood Splitter Needs

Tractor hydraulic fluid is often a jack-of-all-trades fluid designed to handle the transmission, wet brakes, and hydraulics all in one reservoir (this is called UTF or Universal Tractor Fluid). Wood splitters, however, usually only deal with the hydraulic pump and cylinder.

The most common hydraulic fluid specifications needed for wood splitters fall into two main groups:

Group A: AW 30 / ISO 68 (Common for Older or Simpler Splitters)

Many standard consumer or older model splitters often call for a standard AW 30 weight oil. This is very similar to standard motor oil, but hydraulic versions have better anti-wear properties specific to pumps.

- Tractor Equivalent: Many utility tractors use AW 30 or straight-weight 30-weight oil in their non-integrated hydraulic systems, making this fluid easy to source from tractor supply stores.

Group B: ISO 32 or ISO 46 (Common for Newer or High-Performance Splitters)

These are very common industrial hydraulic grades. ISO 32 is a lighter viscosity, often used when temperatures might dip lower, while ISO 46 is slightly thicker and handles higher heat loads better. If your manual specifies ISO 32 or 46, you should try to use a fluid explicitly labeled as “Hydraulic Oil” with that ISO rating.

If you use a UTF (Universal Tractor Fluid) from a tractor supplier, you need to confirm that its technical data sheet lists the required ISO rating (e.g., ISO 46).

Comparison Table: Fluid Specifications

This table helps illustrate why the label matters more than the name “tractor fluid.”

| Fluid Type Name | Common Viscosity (Approx.) | Best For | Wood Splitter Compatibility Note |

|---|---|---|---|

| AW 30 (Straight Weight) | SAE 30 / ISO 68 | Simple hydraulic circuits, older equipment. | Good match if manual specifies SAE 30. |

| ISO 32 Hydraulic Oil | ISO 32 | Moderate climates, standard modern splitters. | Excellent match if manual specifies ISO 32. |

| ISO 46 Hydraulic Oil | ISO 46 | Heavy-duty use, warmer climates. | Excellent match if manual specifies ISO 46. |

| UTF (Universal Tractor Fluid) | Varies Widely | Integrated tractor systems (brakes, transmission, hydraulics). | Use only if UTF specifically states it meets your splitter’s ISO/AW requirement. |

Step 3: Checking Viscosity Ratings for Temperature Control

Why is viscosity so crucial? Imagine trying to push molasses through a tiny straw versus water. Molasses (high viscosity) requires much more effort, especially when cold. Hydraulic pumps are built for a specific “thickness” of fluid.

If you use fluid that is too thin (low viscosity) on a hot day, it thins out too much. This causes metal-on-metal contact inside the pump, leading to wear. If you use fluid that is too thick (high viscosity) on a cold morning, the pump strains to pull it in, starving the system and causing wear before the fluid even warms up.

External Resource Check

For a deeper understanding of how fluid viscosity affects machinery performance, organizations like the American Society of Agricultural and Biological Engineers (ASABE) publish standards on hydraulic fluid selection, which often inform the specifications found in your manuals. You can often find general guidelines on reputable agricultural equipment sites about maintaining proper fluid levels and types for hydraulic efficiency.

Step 4: The Safety Check – Contamination and Mixing

If you are just topping off the fluid, you must consider what is already in the tank. Mixing different hydraulic fluid types is generally frowned upon, even if they look similar.

Never Mix These:

- Standard Motor Oil with AW Hydraulic Oil: While AW 30 motor oil is sometimes acceptable, mixing it with a high-spec ISO 46 hydraulic fluid can upset the additive package and reduce protection.

- Brake Fluid with Hydraulic Oil: These are chemically different and mixing them can ruin seals and damage the system instantly. (This is usually not an issue with wood splitters but is a general hydraulic safety rule.)

- Used Fluid with New Fluid: If the existing fluid is dark, sludgy, or smells burnt, do not just top it off. You need a full flush and replacement with the correct new fluid.

The Best Practice for Topping Off

If you need to add fluid and the current fluid looks clean and clear:

- Identify the exact fluid type currently in the reservoir (if possible).

- If it matches the required specification (e.g., both are ISO 46), top it off carefully.

- If you cannot identify the current fluid, or if it looks different from the tractor fluid you have, it is safest to drain the reservoir completely and refill it with the correct, known fluid. A full change is cheaper than a new pump!

How to Safely Drain and Change the Fluid in Your Wood Splitter

If you decide that replacing the fluid entirely is the safest route, follow these straightforward steps. This is a great DIY project that builds confidence!

Tools and Materials Needed:

- The correct new hydraulic fluid (matching the manual’s ISO/AW spec).

- Large, clean catch pan (rated for at least 5 gallons).

- Wrenches or socket set (to reach the drain plug, if present).

- Funnel with a fine screen filter.

- Clean rags.

- Safety glasses and gloves.

The Step-by-Step Fluid Change Process:

- Safety First: Ensure the engine is off and cool. Disconnect the spark plug wire (for gas-powered models) to prevent accidental starting while you are working near moving parts or near the reservoir cap.

- Locate the Reservoir and Drain: The reservoir is usually a metal tank near the engine or pump. Look for a drain plug on the lowest point of the tank or a large hose connected near the bottom.

- Position the Catch Pan: Place your clean catch pan directly under the drain point. Remember, hydraulic fluid is messy!

- Drain the Old Fluid: Open the drain plug or carefully disconnect the bottom hose. Let the fluid drain completely. This might take a few minutes.

- Inspect the Old Fluid: Look at the fluid in the pan. If you see metal shavings, black sludge, or milky discoloration (water contamination), your system has a serious internal problem that needs professional diagnosis later.

- Replace Components: Reinstall the drain plug tightly (but do not overtighten, as this can crack the housing) or reconnect the hose securely.

- Refill Slowly: Remove the reservoir cap. Place your funnel (with a clean screen filter over the opening) into the reservoir. Pour the new, correct hydraulic fluid slowly.

- Monitor the Level: Watch the sight glass or dipstick. Fill only to the “Full” mark. Do not overfill, as this can cause aeration and foaming.

- Cycle the System: Replace the cap tightly. Reconnect the spark plug wire. Start the engine and cycle the ram (push it out completely, then pull it back in) several times. This forces the new fluid through the entire system.

- Final Check: Shut the engine off. Let the fluid settle for five minutes. Check the sight glass/dipstick one last time and top off slightly if necessary to reach the full mark. Check all drain points for leaks.

Advantages of Using the Correct Hydraulic Fluid (Even if it’s Tractor Grade)

When you use the fluid specified by the manual—whether it happens to be a common tractor fluid type or a dedicated hydraulic oil—you gain several key benefits that save you money in the long run.

Pros of Proper Fluid Selection:

- Maximized Pump Life: Correct viscosity ensures the pump is always lubricated, drastically reducing wear on high-pressure components.

- Consistent Splitting Power: The fluid won’t thin out excessively under load, meaning you maintain full tonnage even when splitting tough wood.

- Seal Longevity: Hydraulic oils are formulated not to degrade the rubber seals and O-rings inside the cylinder and pump, preventing costly leaks.

- Easier Cold Weather Starting: The correct low-temperature rating means your splitter will start easier and perform sooner on chilly mornings.

When Tractor Fluid Might Be a Bad Idea (The Caveats)

While the fluid type might match, the packaging might lie, or the application might be wrong. Here are times to avoid using fluid just because it came from the tractor shed:

- If the Manual Specifies “AW 46 Only”: Do not substitute it with SAE 30 motor oil, even if that’s what you use in the tractor’s engine. Engine oil has different friction modifiers that can harm the hydraulic pump.

- If the Fluid is Old/Stale: If that jug of tractor fluid has been sitting in a damp shed for five years, the additives may have settled or broken down. Always use fresh fluid.

- If You See “Wet Brake” or “Gear Lube” Warnings: Some UTF is designed for transmissions with friction clutches (wet brakes). These fluids contain friction modifiers that can cause hydraulic components to foam or operate sluggishly. If your splitter manual warns against using UTF designed for wet brakes, heed that warning!

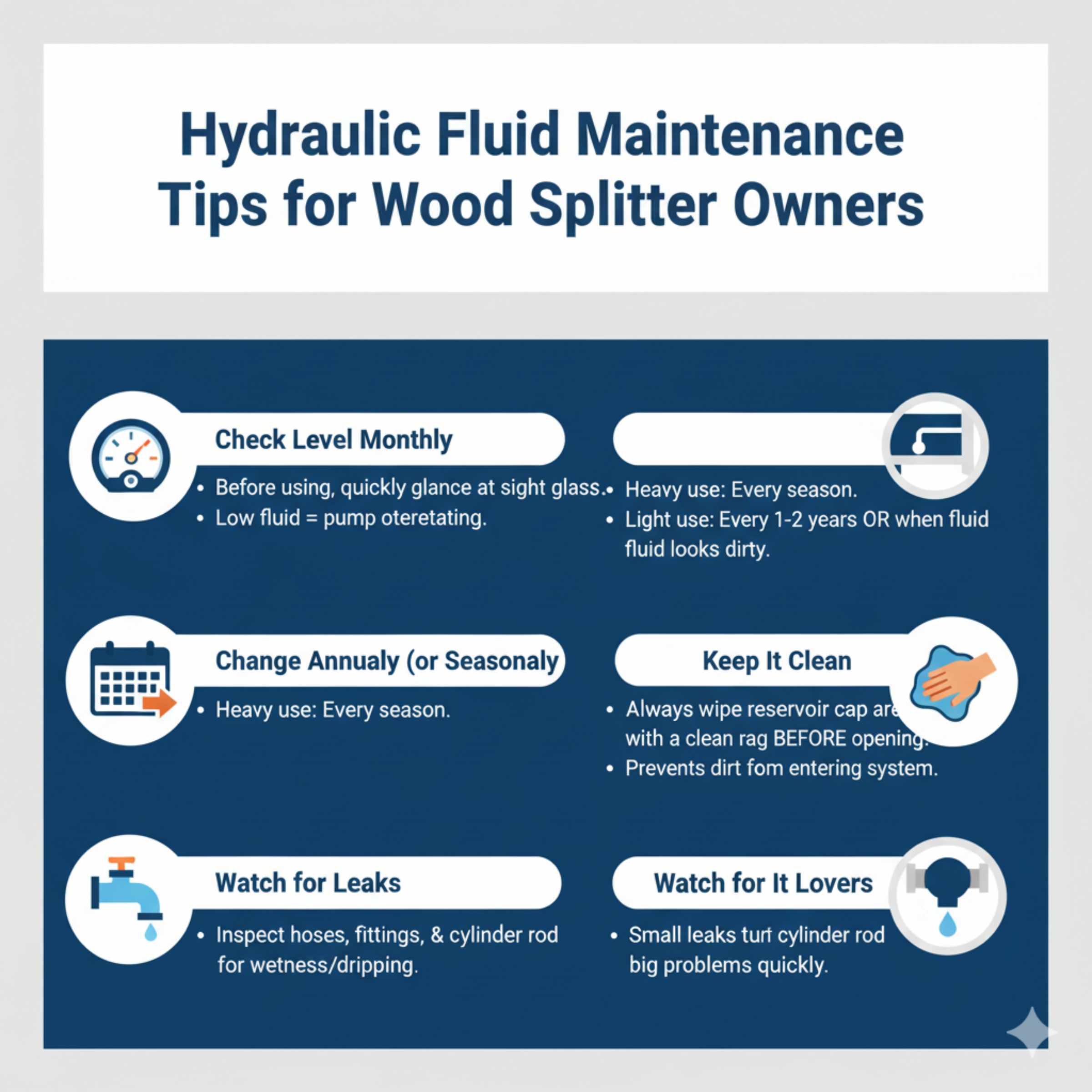

Hydraulic Fluid Maintenance Tips for Wood Splitter Owners

Keeping the right fluid in the tank is only half the battle. Regular maintenance ensures your splitter works reliably year after year. Here are a few easy maintenance habits every homeowner can adopt:

- Check Level Monthly: Before using the splitter, quickly glance at the sight glass. Low fluid is the number one cause of pump overheating.

- Change Annually (or Seasonally): If you use your splitter heavily (splitting cords of wood), change the fluid every season. If you only use it a few weekends a year, change it every two years, or whenever the fluid looks noticeably dirty or dark.

- Keep It Clean: Always wipe down the reservoir cap area with a clean rag before removing the cap. You don’t want dirt falling into your pristine hydraulic system.

- Watch for Leaks: Inspect the hoses, fittings, and the cylinder rod area for any signs of wetness or dripping. Small leaks turn into big problems quickly.

Frequently Asked Questions (FAQ)

Q1: What happens if I put standard motor oil in my wood splitter instead of hydraulic fluid?

A: If your manual calls for AW 30, a high-quality, straight-weight SAE 30 motor oil might work temporarily. However, dedicated hydraulic fluid has superior anti-wear additives for pumps. Using engine oil can lead to overheating and premature wear on the pump seals and bearings over time.

Q2: What type of hydraulic fluid is best for a wood splitter?

A: The best hydraulic fluid is the one specified by the manufacturer. Most wood splitters commonly require AW 30, ISO 32, or ISO 46 hydraulic oil. Using the correct viscosity ensures proper lubrication, pressure, and pump longevity.

Q3: Is Universal Tractor Fluid (UTF) safe for wood splitters?

A: UTF can be used only if the product’s data sheet confirms it meets the required ISO or AW rating for your splitter. Some UTFs contain friction modifiers for wet brakes that may not be ideal for standalone hydraulic systems.

Q4: What happens if you use the wrong hydraulic fluid in a wood splitter?

Using the wrong fluid can cause overheating, poor splitting performance, seal damage, foaming, or premature pump failure. Incorrect viscosity is one of the most common causes of hydraulic system damage.

Q5: Can you mix different hydraulic fluids in a wood splitter?

Mixing hydraulic fluids is not recommended. Different additive packages may react poorly together, reducing lubrication and protection. If you’re unsure what fluid is currently in the system, it’s safest to drain and refill completely.

Conclusion

Yes—you can often use tractor hydraulic fluid in a wood splitter, as long as it meets the exact viscosity and specifications listed in your owner’s manual. The name on the jug matters far less than what’s inside it. Matching the correct ISO or AW rating is the key to protecting your hydraulic pump, maintaining full splitting power, and avoiding costly repairs.

Taking a few minutes to check the manual, confirm fluid specifications, and avoid mixing incompatible oils can dramatically extend the life of your wood splitter. Whether you choose a dedicated hydraulic oil or a compatible tractor fluid, using clean, fresh, properly rated fluid ensures smooth operation in both hot and cold conditions.

When in doubt, a full fluid change with the manufacturer-recommended hydraulic oil is always the safest choice. It’s a small investment that keeps your splitter reliable, powerful, and ready for every tough log you put in front of it!