How Long Before Staining Pressure Treated Lumber

Figuring out the right time to stain your pressure-treated lumber can feel a bit tricky. Many folks wonder, How Long Before Staining Pressure-Treated Lumber? It’s a common question because getting it wrong can lead to your stain not sticking well or even peeling off later. But don’t worry!

We’re here to make it super simple. This guide will walk you through exactly what you need to know, step by step, so your project looks great and lasts.

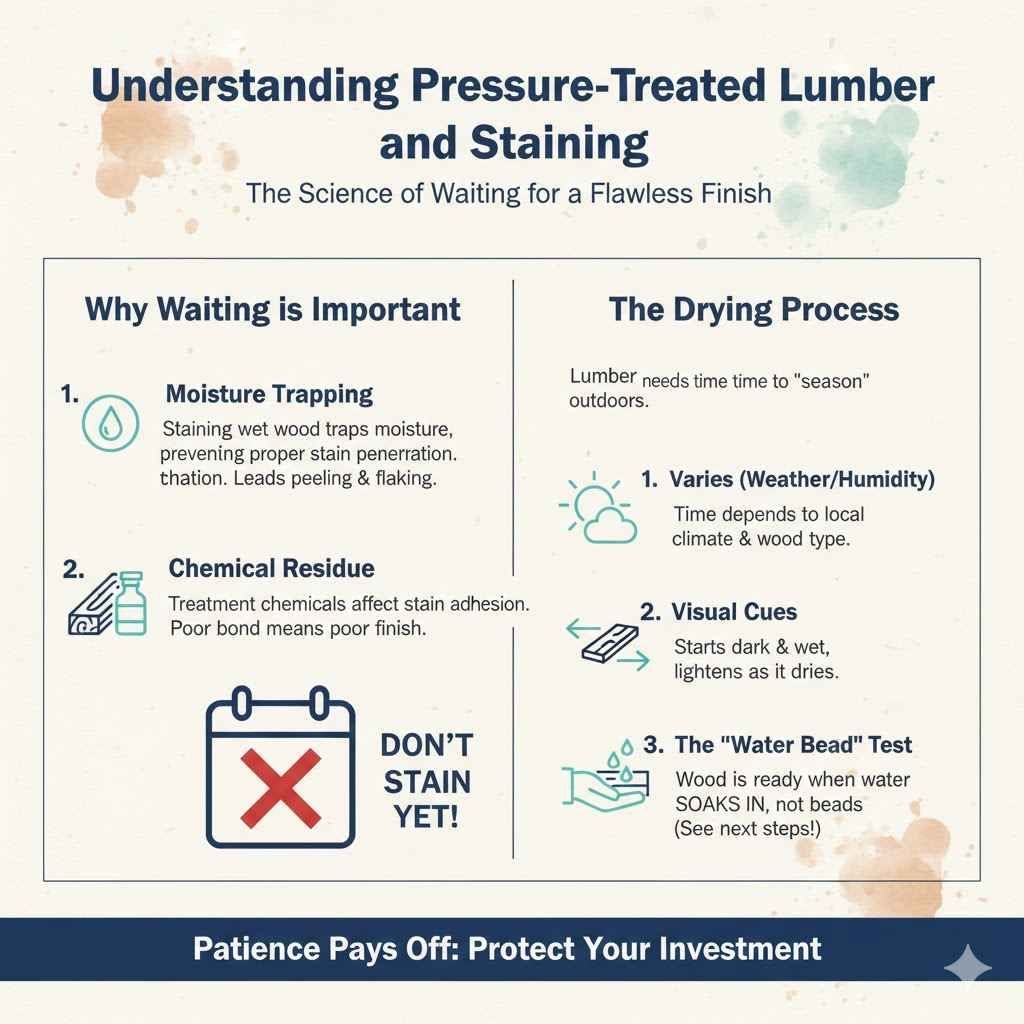

Understanding Pressure-Treated Lumber and Staining

Pressure-treated lumber is wood that has been chemically preserved to resist rot, decay, and insect damage. This makes it perfect for outdoor projects like decks, fences, and pergolas. However, the treatment process leaves the wood with a lot of moisture.

Staining too soon can trap this moisture. This prevents the stain from penetrating the wood properly. It can also lead to the stain peeling or flaking off later.

Why Waiting is Important

The chemicals used in pressure treating can also affect how well stain adheres. These chemicals, along with the moisture, create a surface that is not ideal for staining immediately after purchase. If you apply stain while the wood is still too wet, the stain will sit on the surface rather than soak in.

This results in a poor finish that won’t last long.

The Drying Process

Pressure-treated lumber needs time to dry out after it’s been treated. The amount of time needed can vary quite a bit. Factors like the weather, how humid it is, and the specific treatment process used all play a role.

You’ll notice that new pressure-treated wood often looks darker and feels wet to the touch.

As it dries, the wood will lighten in color and feel drier. This is a good visual cue that it’s getting closer to being ready for stain. The goal is to let enough moisture escape so the wood can absorb the stain.

How Long Before Staining Pressure-Treated Lumber A General Guideline

The most common advice for How Long Before Staining Pressure-Treated Lumber? is to wait. But how long is long enough? Experts and manufacturers often suggest a waiting period.

This period allows the wood to dry out sufficiently. It also lets the chemicals in the wood settle.

The Standard Waiting Period

For most types of pressure-treated lumber, a waiting period of at least 6 to 12 months is recommended. Some sources might say you can stain after as little as 3 months, especially if the wood has dried out considerably. However, a full year gives you the best chance for a lasting finish.

This longer waiting time ensures that the wood has dried evenly and deeply. It allows any excess chemicals to dissipate from the surface. This creates a stable surface for your stain to bond with.

Seasonal Considerations

The time of year you buy and stain your lumber also matters. If you buy lumber in the wet spring or humid summer, it might take longer to dry. Dry, sunny weather in the fall or winter can speed up the drying process.

If you’re in a very humid climate, you might need to wait even longer.

Signs Your Lumber is Ready

Waiting a specific amount of time is a good starting point, but it’s not the only way to tell if your lumber is ready. You can do a simple test. Sprinkle a few drops of water onto the surface of the wood.

If the water beads up on the surface, the wood is still too wet and has a waxy coating. If the water soaks into the wood within a few minutes, it’s likely ready for staining.

The Water Test Explained

This water test is one of the most reliable ways to gauge readiness. When water soaks in, it means the pores of the wood are open and ready to accept a stain. If water beads up, it means the wood’s surface is still repelling moisture.

This is often due to residual treatment chemicals or simply high internal moisture content.

Repeat this test in several spots across the lumber to get a good average reading. Make sure to test on surfaces that will be exposed to the elements.

Factors Affecting Drying Time

Several factors influence how quickly your pressure-treated lumber will dry and be ready for stain. Knowing these can help you estimate the right time.

Wood Type and Thickness

Different types of wood have different densities and absorb moisture differently. Thicker boards will naturally take longer to dry than thinner ones. For instance, large beams for a deck frame will hold moisture longer than 2x4s used for railings.

Weather Conditions

Sunny, dry, and breezy weather is ideal for drying lumber. High humidity, rain, or a lack of airflow will significantly slow down the drying process. If your lumber is stored in a damp or shaded area, it will take longer to dry.

Lumber Storage

How the lumber is stored before you use it makes a difference. If it’s stacked with good airflow between boards and exposed to sun and wind, it will dry faster. Lumber stored in a covered, damp area will dry very slowly.

The Treatment Process

Different manufacturers use slightly different pressure-treating methods and chemical solutions. Some treatments are designed to release moisture more quickly than others. Always check the manufacturer’s recommendations if you can find them.

When Can You Stain Treated Lumber Immediately

While the general rule is to wait, there are rare situations and specific products that allow for quicker staining. However, for most DIYers and standard products, immediate staining is not recommended.

Specialty Stains and Sealers

Some modern stains and sealers are formulated to work on newer lumber. These products often have special wetting agents or binders that can help them adhere to wood with higher moisture content. If you plan to stain immediately, you must use one of these specialized products and carefully follow the manufacturer’s instructions.

Newer Treatment Methods

Some newer pressure-treating methods are designed to reduce the drying time needed before finishing. These might involve different chemical solutions or processes that leave less residual moisture. Again, checking the product label or consulting the manufacturer is key.

DIY Staining Kits

You might see DIY kits or products that claim you can stain right away. Be cautious. While some might work under ideal conditions, they are often less forgiving than waiting.

The risk of poor adhesion or premature failure is higher.

Best Practices for Staining Pressure-Treated Lumber

Once you’ve determined that your lumber is ready, follow these best practices for a beautiful and long-lasting finish.

Preparation is Key

Even if the wood is dry, it’s essential to prepare the surface. Sweep away any dirt, debris, or cobwebs. If the wood has been exposed to the elements for a while, it might have developed a gray, weathered look.

You may need to clean it with a wood brightener or a deck cleaner. Always rinse thoroughly and let the wood dry again before staining.

Choosing the Right Stain

Select a high-quality stain designed for exterior use. Stains come in various opacities, from transparent to solid. Transparent stains show the most wood grain, while solid stains provide the most protection and color, similar to paint.

Semi-transparent stains offer a balance.

Consider a stain that contains UV inhibitors to protect the wood from sun damage and a mildewcide to prevent mold and algae growth.

Application Methods

You can apply stain using a brush, roller, or sprayer. A brush is good for detailed work and for working the stain into the wood grain. Rollers are efficient for large flat areas like deck boards.

Sprayers can be fast but require careful masking to avoid overspray and often need back-brushing to ensure even coverage.

Applying Multiple Coats

Most stains recommend one or two coats. Apply the first coat evenly and allow it to dry according to the manufacturer’s instructions. If a second coat is needed, apply it in the same manner.

Avoid applying stain in direct sunlight or on hot wood. This can cause the stain to dry too quickly, leading to lap marks and an uneven finish.

Temperature and Weather

Always check the weather forecast before you begin. You’ll want a few consecutive dry days with moderate temperatures (ideally between 50°F and 80°F or 10°C and 27°C). Avoid staining if rain is expected within 24-48 hours.

Troubleshooting Common Staining Issues

Even with careful planning, you might encounter some problems. Here’s how to fix them.

Peeling or Flaking Stain

This is usually caused by staining wood that was too wet or not properly prepared. If the peeling is minor, you might be able to sand it down and reapply stain after the wood has thoroughly dried. For widespread peeling, you may need to strip the old stain completely and start over.

Uneven Color or Lap Marks

This often happens when stain is applied too quickly, in direct sun, or when working in sections without blending. It can also occur if the wood’s moisture content is uneven. If caught early, you might be able to reapply a thin coat or use a stain conditioner to blend the color.

For significant issues, you might need to sand and reapply.

Mold or Mildew Growth

This can happen if the stain didn’t fully penetrate or if the wood wasn’t treated for mildew resistance. Regular cleaning with a deck cleaner and a stiff brush can help. Ensure good airflow around the structure.

Frequently Asked Questions

Question: How long do I have to wait to stain pressure-treated wood after it’s purchased?

Answer: Generally, you should wait at least 6 to 12 months. Some may be ready sooner, but a longer wait ensures the wood is dry enough.

Question: Can I use a moisture meter to test if my pressure-treated lumber is ready for stain?

Answer: Yes, a moisture meter is an excellent tool. Most stains require the wood to be below 15% moisture content.

Question: What happens if I stain pressure-treated lumber too soon?

Answer: The stain might not penetrate properly, leading to peeling, flaking, or an uneven finish. It can also trap moisture inside the wood.

Question: Is it okay to stain pressure-treated wood in the winter?

Answer: Yes, if the weather is dry and temperatures are above freezing and within the stain manufacturer’s recommended range. Dry winter air can help wood dry out.

Question: What is the water test for lumber readiness?

Answer: Sprinkle a few drops of water on the wood. If it soaks in within minutes, the wood is likely ready. If it beads up, it’s still too wet.

Final Thoughts

Knowing How Long Before Staining Pressure-Treated Lumber? is key to a beautiful finish. Waiting several months to a full year is usually best. Always do the water test to be sure.

Prepare your wood well and choose a good quality exterior stain. Applying it carefully will protect your project and make it look great for years.