How Long Should You Wait to Stain Pressure Treated Wood: Quick Tips

You should wait at least 6 months before staining pressure-treated wood to ensure it’s fully dried. Staining too soon can lead to poor adhesion and interfere with the wood’s treatment protection.

Staining pressure-treated wood offers both protection and aesthetic appeal. It’s important to understand the proper timing for staining to ensure the best results. Pressure-treated wood is infused with preservatives that prevent decay and insect damage. However, the wood needs time to dry before applying any stain or sealant.

We’ll explore the optimal timing for staining pressure-treated wood, how to test if the wood is ready, and the potential consequences of staining too soon. Following these guidelines will help you achieve a beautiful and long-lasting finish for your pressure-treated wood projects.

Introduction To Pressure Treated Wood

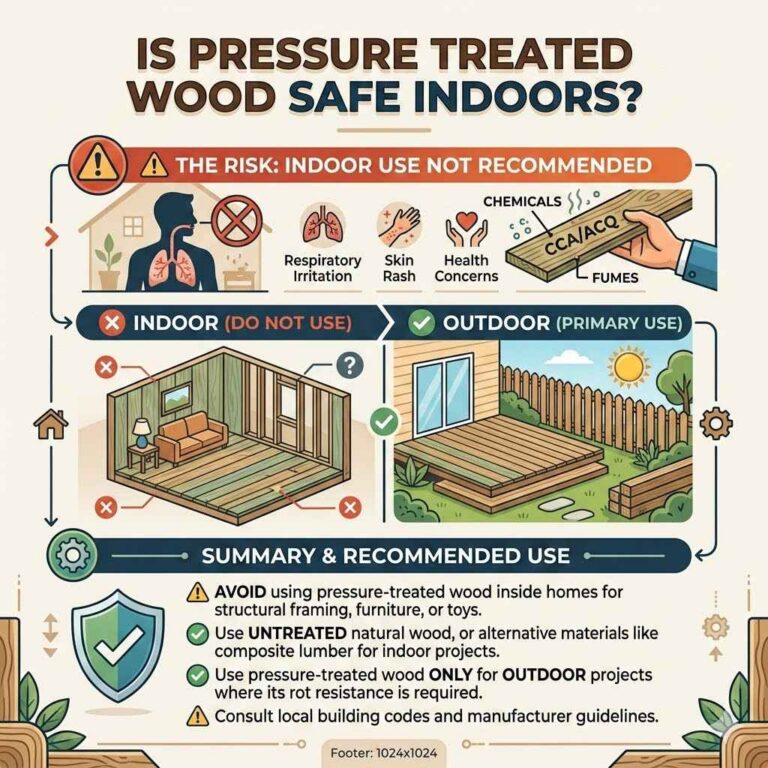

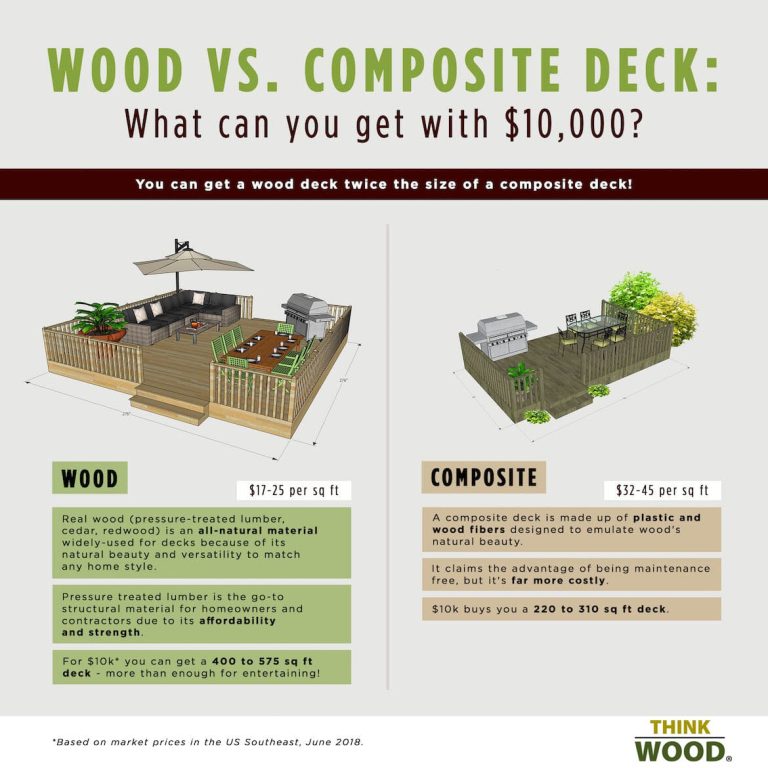

Pressure treated wood is a popular choice for outdoor projects due to its durability and resistance to decay and insect damage. It is commonly used for decks, fences, and other outdoor structures. In this section, we will explore the basics of pressure treating and the benefits of staining pressure treated wood.

The Basics Of Pressure Treating

Pressure treating is a process where wood is infused with chemicals to enhance its resistance to rot, decay, and insects. The wood is placed in a pressure chamber and subjected to high pressure, allowing the preservatives to penetrate deep into the wood fibers. This process creates a long-lasting and durable material that can withstand the harsh outdoor elements.

Benefits Of Staining Pressure Treated Wood

Staining pressure treated wood offers several benefits:

- Enhanced Aesthetics: Staining adds color and enhances the natural beauty of the wood, giving it a more polished and finished look.

- Protection from UV Rays: The sun’s UV rays can cause the wood to fade and gray over time. Stain provides a protective barrier that helps prevent sun damage.

- Water Repellent: Stain helps to repel water, preventing it from soaking into the wood and causing rot or warping.

- Increased Lifespan: By protecting the wood from moisture and UV rays, staining can extend the lifespan of pressure treated wood, saving you time and money on repairs or replacements.

By understanding the basics of pressure treating and the benefits of staining pressure treated wood, you can make informed decisions about when and how to stain your outdoor projects. In the next section, we will discuss how long you should wait to stain pressure treated wood to ensure optimal results.

The Waiting Game

When it comes to staining pressure-treated wood, patience is key. The waiting game can make a significant difference in the final outcome of your project. Understanding the importance of proper drying and the factors affecting drying time is crucial for achieving a successful and long-lasting finish.

Importance Of Proper Drying

Proper drying of pressure-treated wood is essential before applying any stain or sealant. Moisture content in the wood directly impacts how well it will absorb the stain and how effectively the sealant will adhere. Allowing the wood to dry adequately not only ensures better penetration of the stain but also promotes a more durable and uniform finish.

Factors Affecting Drying Time

- Wood Type: Different types of pressure-treated wood may have varying levels of initial moisture content, affecting the drying time.

- Weather Conditions: Environmental factors such as humidity, temperature, and air circulation can significantly influence the drying process.

- Treatment Method: Whether the wood was kiln-dried or air-dried as well as the treatment chemicals used can impact the drying duration.

Identifying The Right Time To Stain

Determining the right time to stain pressure treated wood is crucial for optimal results. It is recommended to wait until the wood is fully dry, which can take several months depending on the climate. Staining too soon can prevent proper absorption and adherence of the finish, while waiting too long may compromise the wood’s protection.

Conducting a simple water test can help determine if the wood is ready for staining.

The Water Drop Test

One method to determine if pressure treated wood is ready to be stained is through the water drop test. Simply drop a few drops of water onto the wood surface. If the water beads up, the wood is not ready to be stained yet. However, if the water is absorbed by the wood quickly, then it is dry and ready for staining.

Using A Moisture Meter

Another way to determine if pressure treated wood is ready for staining is by using a moisture meter. This tool will measure the amount of moisture in the wood. To use, simply press the prongs of the moisture meter into the wood and read the moisture level. If the reading is below 15%, then the wood is dry and ready for staining.

It’s important to wait until the wood is dry before staining it, otherwise, the stain won’t adhere properly and the finish won’t last as long. Additionally, staining too soon can interfere with the pressure treatment protection.

To ensure the best results, always follow the manufacturer’s instructions and recommendations for staining pressure treated wood. Proper preparation and timing will help ensure a beautiful and long-lasting finish.

Prepping Your Wood

When it comes to staining pressure treated wood, it’s important to wait for the wood to dry out before applying any stain. Generally, it’s recommended to wait at least 6 months before staining, but it’s best to test the wood’s moisture content with a moisture meter to ensure it’s ready.

Staining too soon can result in the finish not adhering properly or interfering with the pressure treatment protection.

Before you start staining pressure-treated wood, you need to prepare it properly. This process involves cleaning the surface and sanding (if required).

Cleaning the Surface:

Cleaning the surface is an essential step before staining. You can use a pressure washer or a wood cleaner to clean the surface. However, if you choose to use a wood cleaner, make sure to follow the instructions on the label and rinse the surface thoroughly with water.

Sanding: Yes or No?

Sanding can help to smooth out rough spots and splinters in the wood. However, pressure-treated wood is often already smooth, so sanding may not be necessary. If you do choose to sand the wood, use a fine-grit sandpaper and sand in the direction of the wood grain.

Once you have cleaned and sanded (if needed) the surface, you need to wait for the wood to dry before staining. How long you need to wait depends on the type of pressure-treated wood you have and the weather conditions in your area.

According to experts, you should wait at least 6 months before staining pressure-treated wood. This allows the wood to dry and the chemicals in the treatment to dissipate. However, if you live in a humid or rainy area, you may need to wait longer.

In conclusion, prepping your wood is an important step before staining pressure-treated wood. Cleaning the surface and sanding (if needed) can help to ensure the best results. However, you must wait for the wood to dry before staining to ensure the stain adheres properly.

Choosing Your Stain

When it comes to staining pressure treated wood, choosing the right stain is crucial for achieving the desired look and protection for your project. There are various types of stains available, each with its own characteristics and benefits. Let’s explore the different types of stains for pressure treated wood and some stain application tips to ensure a successful result.

Types Of Stains For Pressure Treated Wood

When selecting a stain for your pressure treated wood, it’s important to consider the type of stain that will best suit your needs. Here are a few common types:

| Stain Type | Description |

|---|---|

| Transparent Stain | This type of stain allows the natural beauty of the wood grain to show through while providing minimal color enhancement. |

| Semi-Transparent Stain | With a semi-transparent stain, you’ll get a bit more color enhancement, while still allowing the wood grain to be visible. |

| Solid Stain | If you’re looking to completely change the color of your pressure treated wood, a solid stain is the way to go. It provides excellent coverage and hides the wood grain. |

Stain Application Tips

Once you’ve chosen the right stain for your pressure treated wood, it’s important to follow these stain application tips to ensure a smooth and long-lasting finish:

- Prepare the wood: Before applying the stain, make sure the wood is clean and free from any dust, dirt, or debris. You can use a power washer or a brush and mild detergent to clean the wood surface.

- Apply the stain evenly: Use a brush, roller, or sprayer to apply the stain evenly across the wood surface. Make sure to follow the manufacturer’s instructions for application techniques and drying time.

- Allow proper drying time: After applying the stain, allow sufficient drying time before using or exposing the wood to any moisture. This will ensure that the stain fully penetrates the wood and provides optimal protection.

- Maintain the stain: To keep your pressure treated wood looking its best, it’s important to regularly maintain the stain. This may involve periodic cleaning, reapplication of stain, or adding a protective topcoat.

By following these stain application tips and choosing the right stain for your pressure treated wood, you can enhance its beauty, protect it from the elements, and prolong its lifespan. Remember to always read and follow the instructions provided by the stain manufacturer for best results.

Common Mistakes To Avoid

To ensure your pressure treated wood is ready for staining, it’s important to wait for it to dry properly. Avoid the common mistake of staining too soon, which can interfere with the wood’s protection and prevent proper adhesion of the finish.

It’s recommended to wait a minimum of one month, but the drying process can take several months depending on the climate and humidity levels.

Staining Too Soon

One common mistake is staining pressure-treated wood too soon. When wood is too wet, it can’t absorb the stain properly, leading to adhesion issues.

Neglecting Weather Conditions

Ignoring weather conditions is another mistake. Staining in high humidity or direct sunlight can cause the stain to dry too quickly, resulting in an uneven finish.

Maintenance And Longevity

To ensure the longevity of pressure treated wood, it’s essential to allow it to dry thoroughly before staining. A simple water test can determine if the wood is ready for treatment: sprinkle a few drops of water on the surface, and if it’s absorbed quickly, the wood is dry and ready to be stained.

Staining pressure treated wood enhances its durability and lifespan. Regular maintenance is crucial to ensure the wood remains protected from the elements and retains its aesthetic appeal.

How Often To Restain

To maintain the appearance and protection of your stained wood, consider restaining every 2-3 years. Regularly checking for signs of wear and weathering can help determine when it’s time for a fresh coat.

Protecting Your Stained Wood

Protect your stained wood by applying a sealant after staining. This helps shield the wood from moisture, UV rays, and other damaging factors. Regularly inspecting the wood for any signs of damage and promptly addressing them can further extend its longevity.

Professional Insights

Expert Advice On Staining

Before staining pressure treated wood, ensure it’s properly dried.

Moisture content affects how stain adheres and protects the wood.

When To Seek Professional Help

If unsure about the wood’s readiness, consult a professional for guidance.

Experts can assess moisture levels and recommend the best staining time.

Faqs On Staining Pressure Treated Wood

To ensure proper adhesion and protection, it is recommended to wait at least one month before staining pressure treated wood. This allows the wood to dry out sufficiently and ensures that the stain will penetrate the surface effectively.

Can You Stain Wood That’s Still Wet?

Staining wet wood leads to poor adhesion and absorption issues.

How Long Can You Wait Before Staining?

Allow pressure treated wood to dry for 6 months before staining.

Frequently Asked Questions

How Long Should Pressure Treated Wood Dry Before Staining?

It is recommended to wait for the pressure-treated wood to dry for at least 6 months before staining. This allows the wood to fully dry and ensures better adhesion of the stain. Testing the wood’s dryness can be done by performing a water test – if the water beads up, the wood is not ready for staining yet.

What Happens If You Stain Pressure Treated Wood Too Soon?

Staining pressure treated wood too soon can result in poor absorption and adhesion, affecting the wood’s protection. Wait for the wood to dry adequately before staining to ensure the best results. Use a simple water test to determine if the wood is ready for staining.

How Can I Determine If Pressure Treated Wood Is Ready For Staining?

Perform a water test by sprinkling a few drops on the wood. If it beads up, wait a few days. If it absorbs quickly, it’s ready for staining.

How Soon Can You Seal Pressure Treated Wood?

You can seal pressure treated wood after it dries, typically within 3-6 months. It’s important to test for dryness by sprinkling water on the wood. If the water is absorbed quickly, it’s ready to be sealed or stained. Avoid sealing too soon to ensure the best protection.

Conclusion

The timing of staining pressure treated wood is crucial for a successful finish. It’s important to allow the wood to dry thoroughly before applying any stain or sealant. By conducting a simple water test, you can determine if the wood is ready for treatment.

Following the recommended drying period will ensure a long-lasting and attractive result for your project.