How to Figure Out How Much Wood I Need: Expert Tips & Strategies

To figure out how much wood you need, calculate the dimensions of the area and consider the type of wood and its coverage per unit. This will give you an accurate estimate of the amount required.

Determining the amount of wood needed for your project is essential to avoid unnecessary expenses or shortages. Whether you’re planning to build furniture, fences, or even decking, understanding how much wood you need is crucial. By carefully calculating the dimensions of the area and factoring in the type of wood you’ll be using, as well as its coverage per unit, you can ensure an accurate estimate.

This guide will provide you with easy-to-follow steps and tips to help you figure out exactly how much wood you need for your project, ensuring a smooth and cost-effective process. So, let’s dive in and get your calculations underway!

Calculating Your Wood Needs

When planning a woodworking project, one of the most important things to consider is how much wood you will need. Accurately calculating your wood needs ensures you have just enough to complete the project without wasting materials. In this section, we will guide you through the process of measuring the project area and determining the type and size of wood needed.

Measuring The Project Area

The first step in calculating your wood needs is to measure the project area. Start by using a tape measure to determine the length and width of the space where the wood will be used. Be sure to measure any corners or angles accurately, as they can affect the amount of wood needed.

Once you have the measurements, calculate the total area in square feet by multiplying the length and width. For example, if the length is 6 feet and the width is 4 feet, the total area would be 24 square feet.

Determining The Type And Size Of Wood

After measuring the project area, the next step is to determine the type and size of wood that would work best for your project. Consider the purpose of the wood, whether it will be used for structural or decorative purposes, as well as the aesthetics you want to achieve.

Wood comes in various types such as hardwood, softwood, plywood, and engineered wood. Each type has its own characteristics and strengths, so choose the one that suits your project requirements.

Additionally, you will need to decide on the size of the wood, which refers to its dimensions such as thickness, width, and length. Carefully consider the specifications provided by your project plans or design and choose the appropriate size accordingly.

If you are uncertain about the type and size of wood to use, consult with a knowledgeable professional or refer to reputable woodworking resources for guidance. Properly selecting the right wood type and size ensures the success and longevity of your project.

Understanding Wood Measurement Units

When it comes to planning a woodworking project, one of the first questions that comes to mind is, “How much wood do I need?” Understanding the measurements and units used in the wood industry is crucial in accurately estimating the amount of wood required for your project. In this article, we will explore two common wood measurement units: board feet and dimensional lumber.

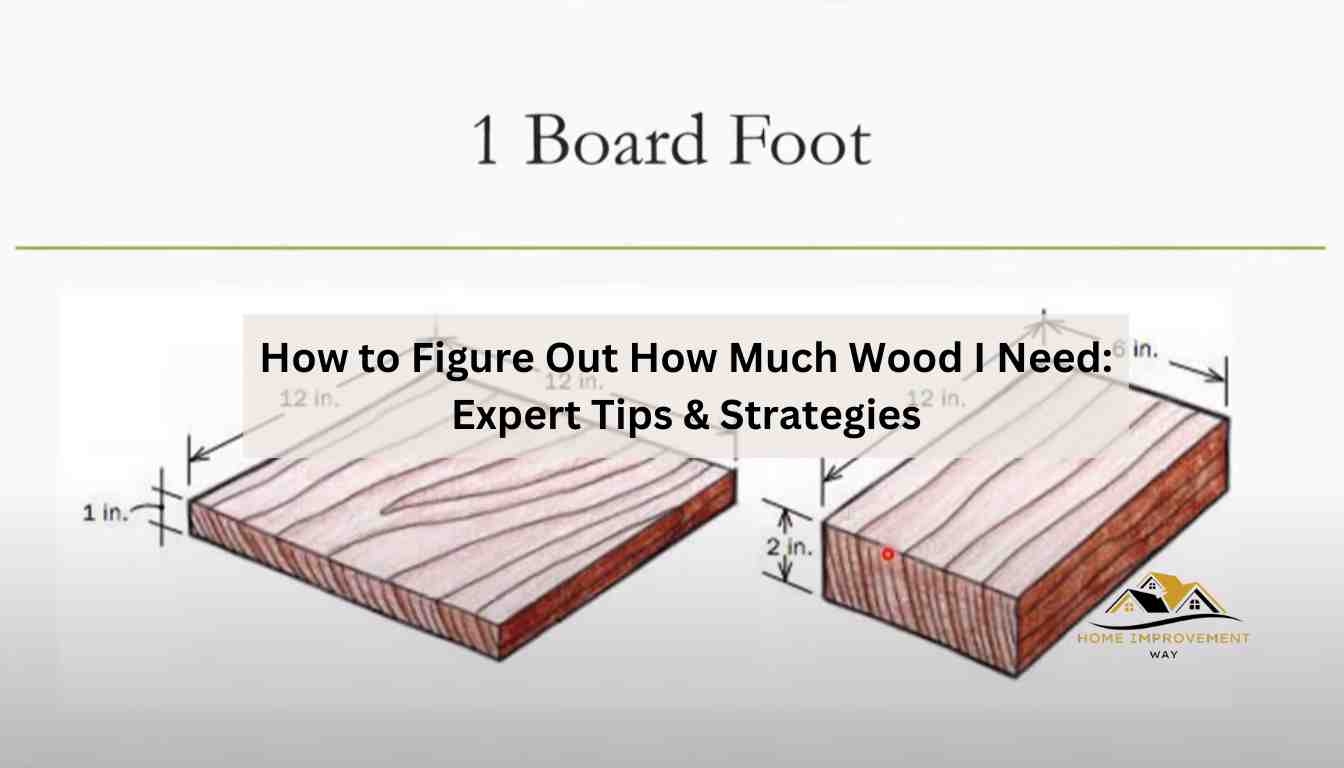

Exploring Board Feet

Board feet is a standard unit of measurement used in the lumber industry to measure the volume of lumber. It is calculated based on the thickness, width, and length of a board.

Here’s the formula to calculate board feet:

Board Feet = (Thickness (in inches) x Width (in inches) x Length (in feet)) / 12

For instance, if you have a piece of wood that is 2 inches thick, 6 inches wide, and 8 feet long, you can calculate the board feet as follows:

Board Feet = (2 x 6 x 8) / 12 = 8 board feet

Understanding board feet allows you to accurately estimate the amount of wood you’ll need for your project and ensures you don’t end up with too much or too little.

Grasping The Concept Of Dimensional Lumber

Dimensional lumber is another common unit of measurement used in the woodworking industry. It refers to pre-cut pieces of wood that are commonly used in construction and woodworking projects, such as 2x4s or 1x6s.

It’s important to note that the actual dimensions of dimensional lumber differ from their nominal sizes. For example, a 2×4 board actually measures 1.5 inches thick and 3.5 inches wide. This difference is due to the milling and drying process.

Here are some commonly used dimensional lumber sizes and their actual dimensions:

| Nominal Size | Actual Dimensions |

|---|---|

| 2×4 | 1.5 inches thick, 3.5 inches wide |

| 1×6 | 0.75 inches thick, 5.5 inches wide |

| 4×4 | 3.5 inches thick, 3.5 inches wide |

Understanding the actual dimensions of dimensional lumber will help you make precise calculations and ensure that the wood you purchase fits perfectly into your project.

Factoring In Waste And Additional Cuts

When planning for a woodworking project, it’s crucial to consider the potential waste and the need for additional cuts. By factoring in these aspects, you can ensure that you have the right amount of wood for the job while accounting for any errors or unexpected requirements.

Accounting For Waste

To avoid running short on materials, it’s essential to account for waste when calculating the amount of wood needed. Typically, it’s recommended to allocate an extra 10-15% for waste, which accounts for cutting errors, damaged pieces, and imperfect sections of the wood. By factoring in this additional amount, you can avoid the frustration of running out of wood mid-project.

Considering Extra Cuts And Errors

In addition to waste, it’s also important to consider the potential need for extra cuts and the possibility of errors. By planning for these contingencies, you can ensure that you have enough wood to accommodate any unforeseen adjustments or mistakes that may arise during the construction process. This proactive approach can save time and prevent unnecessary delays in completing your project.

Consulting Woodworking Resources

When it comes to determining how much wood you need for your woodworking project, consulting woodworking resources can be invaluable. Whether you’re a beginner or an experienced woodworker, tapping into online calculators and seeking advice from professionals can help you accurately estimate the amount of wood required.

Utilizing Online Calculators

Online calculators are user-friendly tools that can calculate the quantities of wood needed based on your project specifications. Simply input the dimensions and details of your project, and the calculator will provide estimates for the amount of wood required. This resource can save you time and effort in manually calculating the quantities.

Seeking Advice From Professionals

Professional woodworkers possess valuable expertise and can offer personalized guidance on determining the right amount of wood for your project. Whether you consult with a local woodworking shop or connect with an online woodworking community, seeking advice from experienced professionals can ensure you get accurate estimations and recommendations for your specific project.

Comparison Of Wood Suppliers

When determining how much wood you need for your project, comparing wood suppliers is crucial.

Evaluating Quality And Price

Quality and price are key factors in selecting a wood supplier.

Considering Sustainable And Eco-friendly Options

Choosing sustainable and eco-friendly wood options benefits both the environment and your project.

Credit: www.amazon.com

Budgeting For Wood Expenses

Budgeting for wood expenses is a critical step in any construction or woodworking project. To ensure that you have enough wood to complete your project while staying within your budget, you need to estimate your project costs and consider alternative wood materials. Estimating project costs can help you determine how much wood you’ll need, while exploring alternative wood materials can save you money without compromising on quality.

Estimating Project Costs

To estimate your project costs, start by calculating the total area or volume that needs to be covered with wood. Then, calculate the cost per unit of wood and multiply it by the total area or volume to determine the total cost of wood for your project. It’s also wise to include a contingency amount in your budget to account for any unexpected expenses that may arise during the project.

Considering Alternative Wood Materials

When planning your project, consider alternative wood materials that may be more cost-effective without compromising on quality. Plywood and engineered wood are affordable options that can be used in place of solid wood for various projects. These materials offer durability and versatility at a lower cost, making them a viable alternative for budget-conscious individuals.

Efficient Wood Handling And Storage

Efficient wood handling and storage are crucial when it comes to figuring out how much wood you need for your project. By optimizing wood cuts and properly storing excess wood, you can reduce waste, save money, and ensure you have enough wood to complete your project without multiple trips to the lumberyard.

Optimizing Wood Cuts

One way to efficiently handle your wood is by optimizing wood cuts. By carefully planning and measuring your cuts, you can minimize waste and maximize the amount of usable wood. Here are a few tips to help you optimize your wood cuts:

- Measure twice, cut once: Take accurate measurements of your project’s dimensions before cutting any wood. This ensures you minimize errors and avoid unnecessary waste.

- Create a cut list: Make a detailed plan of the required cuts, including the length and width for each piece. Organize the list to minimize the number of cuts and maximize the usage of each board.

- Consider board sizes: Take into account the standard sizes of lumber available to you. This way, you can optimize your cuts to make the most of the available stock sizes and minimize waste.

- Plan for extra: Factor in a small margin of error or extra length for each cut. This will give you some flexibility during construction and ensure you don’t fall short on wood.

Properly Storing Excess Wood

When working on a project, you might end up with excess wood after all your cuts are made. Properly storing this wood is essential to maintain its quality and usability for future projects. Here are some tips for storing excess wood:

- Keep it off the ground: Store your wood on racks, pallets, or any elevated surface to prevent moisture absorption from the ground.

- Cover it up: Protect your wood from dust, moisture, and direct sunlight by covering it with a tarp or plastic sheet.

- Choose a dry area: Store your wood in a dry and well-ventilated space to prevent mold or decay.

- Organize by size and type: Organize your excess wood by size and type for easy access and efficient storage.

By following these tips for efficient wood handling and storage, you can ensure you have enough wood for your project, reduce waste, and make the most of your available resources.

Adapting To Changes In The Project

In adapting to changes in the project, it is essential to accurately calculate the necessary amount of wood required. Begin by measuring the dimensions of the project area and estimating the quantity of wood needed based on these measurements. Consistently reassess and adjust the wood requirements throughout the project as needed.

Managing a woodworking project can be an exciting and rewarding endeavor, but it’s not uncommon for changes to arise along the way. Whether due to design modifications or unexpected circumstances, being able to adapt and make adjustments to your wood orders is crucial to keeping your project on track. In this section, we will explore strategies for managing scope changes and resizing or adjusting wood orders, ensuring that you have the right amount of wood to complete your project.

Managing Scope Changes

One of the challenges you may face during a woodworking project is managing scope changes. These changes can vary in magnitude, from minor adjustments to major redesigns. To effectively navigate through these changes, consider the following tips:

- Stay in Communication: Regularly communicate with your project stakeholders, including clients, contractors, or other team members involved. This helps to ensure that everyone is aware of any modifications or alterations to the scope.

- Document Changes: Keep a detailed record of all changes that occur throughout the project. This includes revised plans, revised specifications, and any additional requirements. Having a clear and organized documentation can help minimize confusion and ensure that everyone is on the same page.

- Assess Impact: Determine the impact of each scope change. This involves analyzing the resources, including wood, that will be affected by the modification. By assessing the impact, you can better understand the adjustments that need to be made to your wood orders.

- Collaborate with Suppliers: Consult with your wood suppliers to discuss any alterations in your wood orders. They can provide valuable insights and recommendations on how to adapt your orders to meet the revised project requirements.

- Adjust Timeline and Budget: Lastly, be prepared to modify your project timeline and budget accordingly. Scope changes often result in shifts in deadlines and financial considerations. By adjusting your timeline and budget, you can ensure that you have enough time and resources to accommodate the changes.

Resizing Or Adjusting Wood Orders

When scope changes necessitate resizing or adjusting your wood orders, there are several strategies you can employ:

- Review the Updated Plans: Carefully review the updated plans to determine the new wood requirements. Note any additions, subtractions, or modifications that need to be made to your initial order.

- Calculate Wood Quantities: Use a reliable wood volume calculator to calculate the new quantities of wood needed. Take into account any waste factors, such as cutting losses or damaged pieces, to ensure you have enough wood to complete the project.

- Check Supplier Inventory: Reach out to your wood supplier to verify their inventory and availability. If adjustments need to be made to your initial order, inquire about the possibility of exchanging or returning excess wood or acquiring additional wood.

- Consider Alternatives: In case your initial wood order cannot be resized or adjusted, explore alternative wood options that may be readily available. Discuss with your supplier the feasibility of using different wood species or sizes that can still meet the project’s requirements.

- Revise Budget: Re-evaluate your project budget to account for any changes in wood orders. Make the necessary adjustments to ensure that the revised wood quantities align with your financial resources.

By effectively managing scope changes and resizing or adjusting your wood orders, you can confidently adapt to any changes that arise during your woodworking project. This allows you to maintain control while ensuring that you have the right amount of wood to bring your vision to life.

Credit: superiorfencecosa.com

Frequently Asked Questions On How To Figure Out How Much Wood I Need

How Do You Calculate How Much Lumber You Need?

To calculate lumber needed, measure project dimensions, factor in waste, and divide total linear feet by board feet per thickness.

What Is The Formula For Determining The Amount Of Wood?

To determine the amount of wood, use the formula: Length x Width x Height = Total volume.

How Do I Know How Many 2×4 I Need?

To calculate the number of 2x4s needed, measure the length in feet and divide by 8. For example, 16-foot long wall requires 32 2x4s.

How Much Wood Do I Need For A 2000 Square Foot House?

For a 2000 square foot house, you would need approximately [insert amount] of wood. Keep in mind that this is an estimate and the exact amount may vary depending on the design and construction requirements of your house. It is recommended to consult with a professional builder or contractor to determine the precise quantity needed.

Conclusion

Calculating the amount of wood needed is crucial for any project. By following the steps outlined you can accurately determine the quantity necessary for your specific needs. Remember to consider factors like waste, overage, and potential errors to ensure you have enough wood for your project.

With these tips, you can confidently plan and purchase the right amount of wood for your next undertaking.