Top Wheels For A Table Saw: Enhance Mobility Today!

When selecting wheels for a table saw, precision engineering and robust design are paramount to enhancing mobility and ensuring optimal stability during operation. These specialized wheels must accommodate the weight distribution of heavy machinery while providing seamless maneuverability across varied surfaces. Key factors such as load capacity, tread composition, and locking mechanisms play a critical role in determining the efficacy and safety of the wheels.

Understanding the various specifications and models available can significantly improve both workflow efficiency and workspace organization. To delve deeper into the intricate details of choosing the right wheels for your table saw, continue reading the full article.

Choosing The Best Wheels For A Table Saw: A Complete Guide

Choosing the right wheels for a table saw can significantly enhance mobility and workspace efficiency. The ideal wheels not only improve portability but also provide stability during operation. Factors such as wheel size, material, load capacity, and attachment style play crucial roles in ensuring a safe and functional setup. Understanding these elements is essential for any woodworker looking to optimize their table saw’s performance while maintaining ease of movement throughout their workshop or job site.

Understanding the Importance of Wheels for a Table Saw

Role of wheels in mobility and stability. Impact on workspace efficiency.

Wheels play a crucial role in making a table saw easy to move. They provide mobility, allowing users to transport the saw quickly when needed. This saves time and energy during projects.

Moreover, wheels enhance stability when locked in place.

A steady saw ensures safer cutting and better results. With wheels, you can rearrange your workspace without hassle, improving overall efficiency.

- Quick movement to different areas

- Stable cutting surface

- Enhanced workspace organization

Types of Wheels for Table Saws

Fixed wheels vs. swivel wheels. Material options: plastic, rubber, and metal.

Choosing the right wheels for your table saw can feel like picking shoes for a dance party. You want fixed wheels for stability, or swivel wheels for smooth moves around corners. Each type has its perks, like fixed wheels keeping everything steady, while swivel ones let you turn on a dime.

Then, there’s the material: plastic is lightweight, rubber offers grip, and metal screams durability. It’s like the wheel world is your buffet, but with fewer calories!

| Type | Advantages |

|---|---|

| Fixed Wheels | Stable and sturdy, perfect for long-term setups. |

| Swivel Wheels | Flexible movement, great for tight spaces. |

| Plastic | Lightweight and easy to transport. |

| Rubber | Better grip and shock absorption. |

| Metal | Durable and long-lasting, can handle heavy loads. |

How to Choose the Right Wheel Size for Your Table Saw

Factors influencing wheel size selection. Compatibility with different table saw models.

Choosing the right wheel size can be a bit of a puzzle. Think about your workspace; a small shop may not need giant wheels. Consider the weight of your table saw too. If it’s a hefty model, bigger wheels help with mobility.

Compatibility is key; not all wheels fit every table saw. Check your specific model to avoid a hilarious game of “wheel roulette”.

| Factors | Wheel Size Recommendation |

|---|---|

| Workspace Size | Smaller wheels for tight spaces |

| Table Saw Weight | Bigger wheels for heavier models |

| Model Compatibility | Always check the manual |

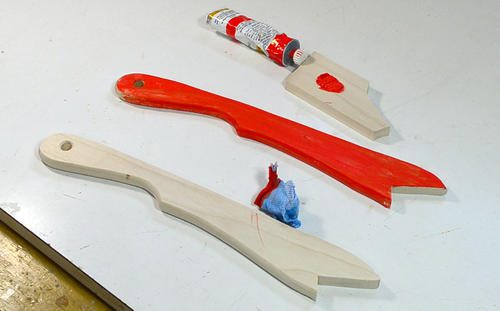

Installation Process for Table Saw Wheels

Stepbystep installation guide. Common tools required for installation.

To install wheels on your table saw, follow these simple steps:

- Gather necessary tools: screwdriver, wrench, and measuring tape.

- Lift the table saw carefully to access the base.

- Align the wheels with the mounting holes.

- Secure each wheel using screws and your screwdriver.

- Double-check the tightness to ensure stability.

- Test the wheels by rolling the saw on a flat surface.

Having these tools will make the process easier:

- Screwdriver

- Wrench

- Measuring tape

With this guide, you’ll have your table saw ready to roll!

Best Brands and Models of Table Saw Wheels

Comparison of toprated brands. Key features of recommended models.

Several brands stand out in the world of table saw wheels. They offer various models with unique features that cater to different needs. Here are some top-rated options to consider:

- Hilti: Known for durability and smooth mobility, these wheels are easy to install.

- DeWalt: Offers a range of sturdy wheels designed for heavy loads and stability.

- Makita: These wheels feature a locking mechanism for secure positioning and quick release.

Each brand has its strengths, making them popular among woodworking enthusiasts.

Maintenance Tips for Table Saw Wheels

How to keep wheels in optimal condition. Signs that wheels need replacement.

Keeping table saw wheels in good shape is important for safety and smooth operation. Regular checks can help you spot problems early. Clean the wheels often to remove dust and debris. Lubricate them with oil to allow easy movement.

Look for these signs that wheels may need replacement:

- Wobbling during use

- Excessive noise while rolling

- Cracks or breaks on the wheels

By following these tips, you can ensure your wheels last longer and work better!

Real User Experiences and Reviews

Case studies of user perspectives. Common issues and solutions from users.

Many users have shared their experiences with wheels for a table saw. They often highlight the importance of smooth movement and stability. Here are some common insights:

- Ease of use: Users appreciate wheels that glide easily.This helps in moving the saw around during projects.

- Sturdiness: A sturdy set of wheels can prevent tipping over, which is a common concern.

- Installation: Quick and easy installation is a must. Users prefer designs that require minimal tools.

Many also report issues with wheel durability. Some suggest shorter wheels can wear down quickly. Solutions include choosing high-quality materials or adding maintenance routines.

Cost Considerations for Purchasing Wheels

Price range analysis for different wheel types. Budgeting tips for table saw upgrades.

Choosing wheels for your table saw involves understanding prices. Different wheel types come with various price tags.

- Standard wheels: Around $20 – $50

- Heavy-duty wheels: $50 – $100

- Locking wheels: $30 – $80

Set a clear budget for upgrades to avoid overspending. Look for sales or discounts to save money.

Planning helps you find the best wheels for your needs.

Conclusion

In summary, choosing the right wheels for a table saw can significantly enhance mobility, precision, and safety in your workshop. Whether you opt for stationary lockable wheels or durable swivel models, investing in quality wheels ensures ease of movement and stability. Upgrade your setup today for a more efficient and productive woodworking experience. Quality wheels can make all the difference!

FAQs

Sure! Here Are Five Related Questions On The Topic Of Wheels For A Table Saw:

1. What types of wheels are best for a table saw stand? 2. How do wheel sizes affect the portability of a table saw? 3. What materials are commonly used for table saw wheels? 4. Can I upgrade the wheels on my existing table saw stand? 5. What safety considerations should I keep in mind when using wheels on my table saw?

Sure! Please provide the question you’d like me to answer.

What Are The Benefits Of Adding Wheels To A Table Saw For Mobility?

Adding wheels to a table saw enhances mobility, allowing for easier movement across a workshop or job site. This mobility facilitates quick setups and adjustments, saving valuable time during projects. It also promotes better space management, enabling users to stow the saw when not in use. Overall, wheeling a table saw contributes to increased efficiency and flexibility in woodworking tasks.

How Do You Choose The Right Type Of Wheels For A Table Saw Based On Its Weight And Design?

Choosing the right wheels for a table saw involves considering both the weight of the saw and its design. For heavier models, opt for larger, sturdier wheels that can support the weight and provide stability during movement. The design of the table saw should also be taken into account, ensuring that the wheels can be mounted securely without interfering with the saw’s operation. Additionally, select wheels with a locking mechanism to prevent any unintended movement when in use.

Are There Specific Wheel Kits Designed For Different Models Of Table Saws, And How Do They Differ?

Yes, there are specific wheel kits designed for different models of table saws. These kits vary in terms of compatibility with saw sizes, weight capacities, and attachment mechanisms. Some wheel kits are tailored for portability, offering features like swivel casters for easier maneuverability, while others focus on stability and durability for larger saws. It’s essential to choose a kit that matches your specific table saw model to ensure proper fit and functionality.

What Installation Considerations Should You Take Into Account When Fitting Wheels To A Table Saw?

When fitting wheels to a table saw, consider the weight and stability of the saw to ensure it can support both the tool and the additional mobility without tipping. Ensure the wheels are lockable to prevent unintended movement during operation. Additionally, assess the floor surface to select appropriate wheel types for smooth mobility. Finally, make sure the wheels are installed at a height that allows for easy maneuverability without compromising the saw’s cutting height or stability.

How Do You Ensure The Stability And Safety Of A Table Saw While Using Wheels For Movement?

To ensure the stability and safety of a table saw with wheels, first, choose a high-quality mobile base designed specifically for the saw’s weight and dimensions. Always engage the locking mechanism on the