Washer Wood Screws: Ultimate Grip & Durability

Washer wood screws feature a flat washer-like head that distributes load evenly. They are ideal for creating sturdy connections in wood.

Washer wood screws are essential for various construction and woodworking projects. Their unique design combines the benefits of a screw and a washer, providing excellent grip and stability. The flat head allows for a flush finish, minimizing the risk of damage to the wood surface.

These screws are particularly useful in applications where strong holding power is necessary, such as decking, furniture assembly, and cabinetry. Available in different sizes and materials, washer wood screws cater to diverse needs, making them a versatile choice for DIY enthusiasts and professionals alike. Understanding their features can help you make informed decisions for your next project.

Introduction To Washer Wood Screws

Washer wood screws are essential fasteners in woodworking. They combine the features of screws and washers. This combination enhances strength and stability. These screws are ideal for various projects. They prevent wood splitting and ensure a secure hold.

Key Features

- Material: Typically made of steel, stainless steel, or brass.

- Coating: Often coated to resist rust and corrosion.

- Thread Design: Designed with sharp threads for easy penetration.

- Washer Head: Provides a larger surface area for better grip.

- Sizes: Available in various lengths and diameters.

Common Uses

Washer wood screws are versatile in their applications.

- Joining wooden pieces in furniture making.

- Securing wooden beams in construction.

- Attaching hardware to wooden surfaces.

- Building decks and outdoor furniture.

- Assembling cabinets and shelves.

| Use Case | Benefits |

|---|---|

| Furniture Making | Strong joints with minimal wood damage. |

| Construction | Reliable connections in structural applications. |

| Outdoor Projects | Resistant to weather and moisture. |

Design And Material

The design and material of washer wood screws are crucial. These factors affect strength, durability, and application. Understanding these elements helps in choosing the right screw.

Screw Anatomy

Washer wood screws feature several important components. Each part plays a specific role:

- Head: The top part that provides grip.

- Washer: A flat disc that distributes load.

- Shaft: The long body that goes into the wood.

- Threads: Helical ridges that grip the material.

Understanding screw anatomy aids in proper use. Each component enhances the screw’s performance.

Material Selection

Choosing the right material affects screw performance. Common materials include:

| Material | Characteristics | Best Use |

|---|---|---|

| Steel | Strong and durable | General woodworking |

| Stainless Steel | Corrosion-resistant | Outdoor projects |

| Brass | Attractive and rust-resistant | Decorative applications |

Consider the project environment. Select a material that suits your needs. Proper material choice ensures longevity and reliability.

Types Of Washer Wood Screws

Washer wood screws come in various types. Each type serves a specific purpose. Understanding these types helps in choosing the right screw for your project.

Flat Washers

Flat washers are simple, round discs. They help distribute the load of a screw. This reduces the risk of damage to the wood. Here are some key features:

- Made of metal or plastic.

- Available in various sizes.

- Ideal for softwood and hardwood.

Flat washers provide stability. They prevent the screw head from sinking into the wood. This is especially useful in soft materials.

Locking Washers

Locking washers keep screws secure. They prevent loosening over time. This is crucial in high-vibration areas.

Here are some important points:

- They have a unique shape.

- Available in split or toothed designs.

- Effective in outdoor projects.

Locking washers enhance durability. They ensure a tight fit, reducing the chance of failure.

| Type | Material | Use |

|---|---|---|

| Flat Washers | Metal/Plastic | Load distribution |

| Locking Washers | Metal | Prevent loosening |

Benefits Of Using Washer Wood Screws

Washer wood screws offer significant advantages for woodworking projects. They ensure a strong connection and enhance durability. Here are key benefits of using them:

Enhanced Load Distribution

Washer wood screws spread the load across a larger area. This reduces pressure on the wood. It helps prevent damage over time.

- Greater stability: The wider surface keeps the screw in place.

- Improved strength: They handle heavier loads without bending.

- Less wear: The washer reduces friction between the screw and wood.

This combination increases the overall strength of your projects. Choose washer wood screws for better performance.

Prevention Of Wood Splitting

Wood can crack easily under pressure. Washer wood screws help prevent this. They distribute the force more evenly.

| Type of Wood | Risk of Splitting | Washer Benefits |

|---|---|---|

| Pine | High | Reduces splitting risk |

| Oak | Medium | Minimizes cracking |

| Maple | Low | Enhances durability |

Using washer wood screws will protect your wood projects. They keep your work looking great and lasting longer.

Installation Tips

Installing washer wood screws correctly ensures strong connections. Follow these tips for a successful installation.

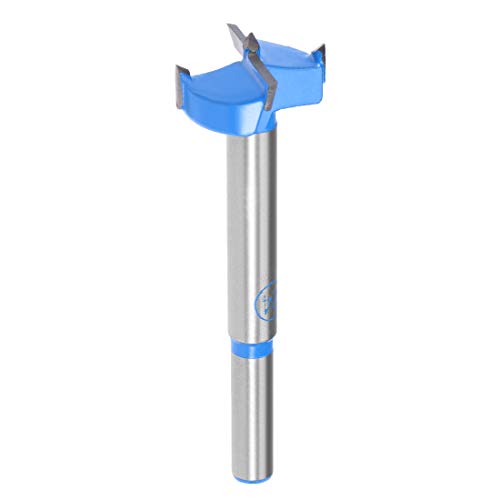

Pre-drilling Holes

Pre-drilling holes helps to prevent wood from splitting. Use the following guidelines:

- Choose a drill bit slightly smaller than the screw’s diameter.

- Drill to a depth matching the screw length.

- Ensure holes are straight and aligned.

Consider this table for drill bit sizes:

| Screw Size | Drill Bit Size |

|---|---|

| #6 | 3/32 inch |

| #8 | 1/8 inch |

| #10 | 9/64 inch |

| #12 | 5/32 inch |

Torque And Tightening

Proper torque ensures washer wood screws hold securely. Follow these steps:

- Use a torque wrench for accuracy.

- Start tightening slowly to avoid stripping.

- Increase torque gradually until secure.

Remember these tips:

- Check the manufacturer’s recommendations for torque settings.

- Don’t overtighten; it may damage the wood.

- Use a screwdriver or drill for consistent pressure.

Comparative Analysis

Understanding the differences between washer wood screws and other types is crucial. This analysis helps in choosing the right screw for your project. Let’s explore two key comparisons: washer vs. non-washer screws and metal vs. wood screws.

Washer Vs. Non-washer Screws

Washer wood screws have a built-in washer. This feature offers unique advantages:

- Increased surface area: Distributes load better.

- Reduces stripping: Prevents damage to the material.

- Improved sealing: Offers better resistance to moisture.

Non-washer screws lack this feature. They may not distribute load as effectively. Here’s a quick comparison:

| Feature | Washer Screws | Non-Washer Screws |

|---|---|---|

| Load Distribution | Better | Less Effective |

| Stripping Resistance | Higher | Lower |

| Moisture Resistance | Enhanced | Standard |

Metal Vs. Wood Screws

Metal screws are strong and durable. They work best for heavy-duty projects. Wood screws are designed specifically for wood. Here are their main differences:

- Material: Metal screws are usually made of steel.

- Thread Design: Wood screws have deeper threads.

- Use Cases: Metal screws are for metal connections.

- Corrosion Resistance: Metal screws may rust without coatings.

Choose wood screws for woodworking tasks. They grip better and reduce splitting. Here’s a simple table summarizing the differences:

| Characteristic | Metal Screws | Wood Screws |

|---|---|---|

| Strength | High | Moderate |

| Thread Depth | Shallow | Deep |

| Best Use | Metal | Wood |

| Corrosion | May rust | Usually treated |

Maintenance And Longevity

Taking care of your washer wood screws enhances their lifespan. Regular maintenance prevents issues like rust and loosening. This section covers key practices for long-lasting screws.

Periodic Checks

Conducting periodic checks keeps your screws in top shape. Here are some tips:

- Inspect screws every few months.

- Look for signs of wear or damage.

- Ensure screws are tight and secure.

- Replace any damaged screws immediately.

Regular inspections help catch problems early. This simple step can save time and money later.

Corrosion Resistance

Corrosion resistance is vital for washer wood screws. Here are key points to consider:

| Material | Corrosion Resistance Level |

|---|---|

| Stainless Steel | High |

| Coated Steel | Medium |

| Plain Steel | Low |

Choose screws with high corrosion resistance for outdoor use. This prevents rust and extends their life. Always store screws in a dry environment. Moisture can quickly lead to corrosion.

Innovations In Screw Technology

Innovations in screw technology have transformed the industry. New materials and features improve performance and sustainability. This section explores two exciting advancements: eco-friendly materials and smart screws.

Eco-friendly Materials

Manufacturers now focus on using eco-friendly materials. These materials reduce environmental impact and enhance durability. Here are some key points:

- Bamboo: Strong and renewable, bamboo screws are a great option.

- Recycled Metals: Using recycled metals cuts down on waste.

- Biodegradable Plastics: These plastics break down naturally over time.

Switching to eco-friendly materials helps protect our planet. Many consumers prefer these sustainable options. They offer similar performance to traditional screws but with less harm.

Smart Screws

Smart screws are another exciting innovation. These screws come with advanced features. They can monitor their own performance. Here are some benefits:

| Feature | Benefit |

|---|---|

| Self-Tightening | Automatically adjusts tension, preventing loosening. |

| Integrated Sensors | Detects stress and alerts users before failure. |

| Smartphone Connectivity | Provides real-time data on screw performance. |

Smart screws enhance safety and reliability. They are ideal for critical applications. These innovations are changing how we think about fastening technologies.

Choosing The Right Screw For Your Project

Choosing the right screw is essential for your project’s success. Washer wood screws are popular for their durability and versatility. Understanding the key factors helps in making the best choice. Pay attention to size, length, and load-bearing capacity.

Size And Length Considerations

Size and length are crucial for proper fastening. Using the wrong size can weaken the structure. Here are some tips to guide your selection:

- Gauge Size: Choose a gauge that fits your project needs.

- Length: Measure the thickness of the materials you are joining.

- Minimum Length: Use screws that are at least twice the thickness of the thinner material.

For example:

| Material Thickness (inches) | Recommended Screw Length (inches) |

|---|---|

| 1/2 | 1 |

| 3/4 | 1.5 |

| 1 | 2 |

Load-bearing Capacity

Load-bearing capacity determines how much weight a screw can hold. Choosing screws with the correct capacity ensures safety and stability. Consider these factors:

- Material: Hardwoods require stronger screws than softwoods.

- Thread Design: Coarse threads grip better in soft materials.

- Diameter: Thicker screws generally hold more weight.

Use the following guidelines:

- For light loads, use smaller screws (1.25 to 1.5 inches).

- For medium loads, consider screws between 2 to 3 inches.

- For heavy-duty applications, opt for screws longer than 3 inches.

Always check the manufacturer’s specifications for precise load limits.

Case Studies

Exploring real-life applications of washer wood screws can provide valuable insights. These case studies highlight successful builds and the lessons learned during the process.

Successful Builds

Many projects have benefited from using washer wood screws. Here are a few examples:

- Deck Construction: A family built a sturdy deck using these screws. They provided excellent support.

- Furniture Assembly: A woodworking shop used washer wood screws in tables. The screws ensured durability and stability.

- Outdoor Structures: A community center constructed a gazebo. Washer wood screws helped withstand weather conditions.

Lessons Learned

Projects using washer wood screws often reveal important lessons. Here are some key takeaways:

- Proper Sizing Matters: Always choose the right screw length and diameter.

- Pre-drilling is Essential: Pre-drill holes to avoid splitting wood.

- Quality Counts: Invest in high-quality screws for better performance.

- Weather Resistance: Select screws with corrosion resistance for outdoor use.

| Project Type | Key Benefits | Challenges |

|---|---|---|

| Deck Construction | Strong support, long-lasting | Weather exposure |

| Furniture Assembly | Stability, aesthetic appeal | Weight distribution |

| Outdoor Structures | Durability, safety | Installation difficulty |

Future Trends In Fastening

The fastening industry is evolving rapidly. New technologies and materials are changing how we use screws. Washer wood screws are at the forefront of these changes. They offer better performance and versatility. Understanding future trends helps in making informed decisions.

Advancements In Manufacturing

Manufacturing processes for washer wood screws are becoming more advanced. Automation plays a big role in this shift. Here are some key advancements:

- 3D Printing: Custom screws can be made quickly.

- Smart Technology: Sensors monitor screw integrity.

- Eco-Friendly Materials: Sustainable options are now available.

These advancements lead to:

- Higher quality products.

- Reduced waste in production.

- Faster delivery times.

Emerging Market Demands

Market needs are shifting. Consumers want more durable and reliable products. The demand for washer wood screws is increasing in various sectors:

| Sector | Demand Trend |

|---|---|

| Construction | High demand for strength and durability. |

| Furniture | Focus on aesthetics and functionality. |

| DIY Projects | Growing interest in easy-to-use fastening solutions. |

As markets evolve, so do the specifications for washer wood screws. Manufacturers must adapt to meet these new demands.

Frequently Asked Questions

What Are Washer Wood Screws Used For?

Washer wood screws are primarily used to attach wood pieces securely. The washer increases the surface area of the screw head, distributing pressure evenly. This prevents the wood from splitting and ensures a tighter grip. They’re ideal for various woodworking and construction projects.

How Do I Choose Washer Wood Screws?

Choosing washer wood screws involves considering several factors. First, assess the thickness of the materials you’re working with. Next, select the appropriate length and diameter for your project. Finally, choose the right material, like stainless steel or galvanized, for durability and resistance to corrosion.

Can Washer Wood Screws Be Reused?

Yes, washer wood screws can often be reused if they remain intact. However, their effectiveness can diminish over time due to wear or corrosion. Inspect the threads and washers for any damage before reusing. If they appear compromised, it’s best to use new screws for safety.

Are Washer Wood Screws Better Than Regular Screws?

Washer wood screws offer advantages over regular screws in specific applications. The added washer provides better load distribution and reduces the risk of wood splitting. This makes them preferable for heavy-duty tasks or softer woods. However, the choice depends on your project’s specific requirements.

Conclusion

Washer wood screws are essential for strong and secure connections in woodworking projects. Their unique design helps distribute load evenly, preventing damage to materials. Choosing the right washer screw can enhance durability and performance. Invest in quality screws to ensure your projects stand the test of time.

Happy building!