What Are The Best Screws For Pressure Treated Wood: A Secret

The best screws for pressure-treated wood are hot-dip galvanized, stainless steel, or ceramic-coated. These types prevent rust and corrosion caused by the chemicals in the wood. Using the right screw ensures your project stays strong and looks great for years, avoiding dangerous failures and ugly rust stains. This is the secret to long-lasting outdoor builds.

Hello, friend! I’m Md Meraj, and today we’re going to solve a common problem that trips up many DIYers: picking the right screws for pressure-treated wood. Have you ever built a beautiful deck or fence, only to see ugly rust streaks running down the wood a year later? Or worse, noticed the screws are failing? It’s frustrating, but it’s not your fault. It happens because treated wood is a little different.

The good news is there’s a simple secret to getting it right every time. In this guide, I’ll walk you through exactly what you need. We’ll look at the best options, what to avoid, and how to choose the perfect screw for your project. Let’s build something that lasts!

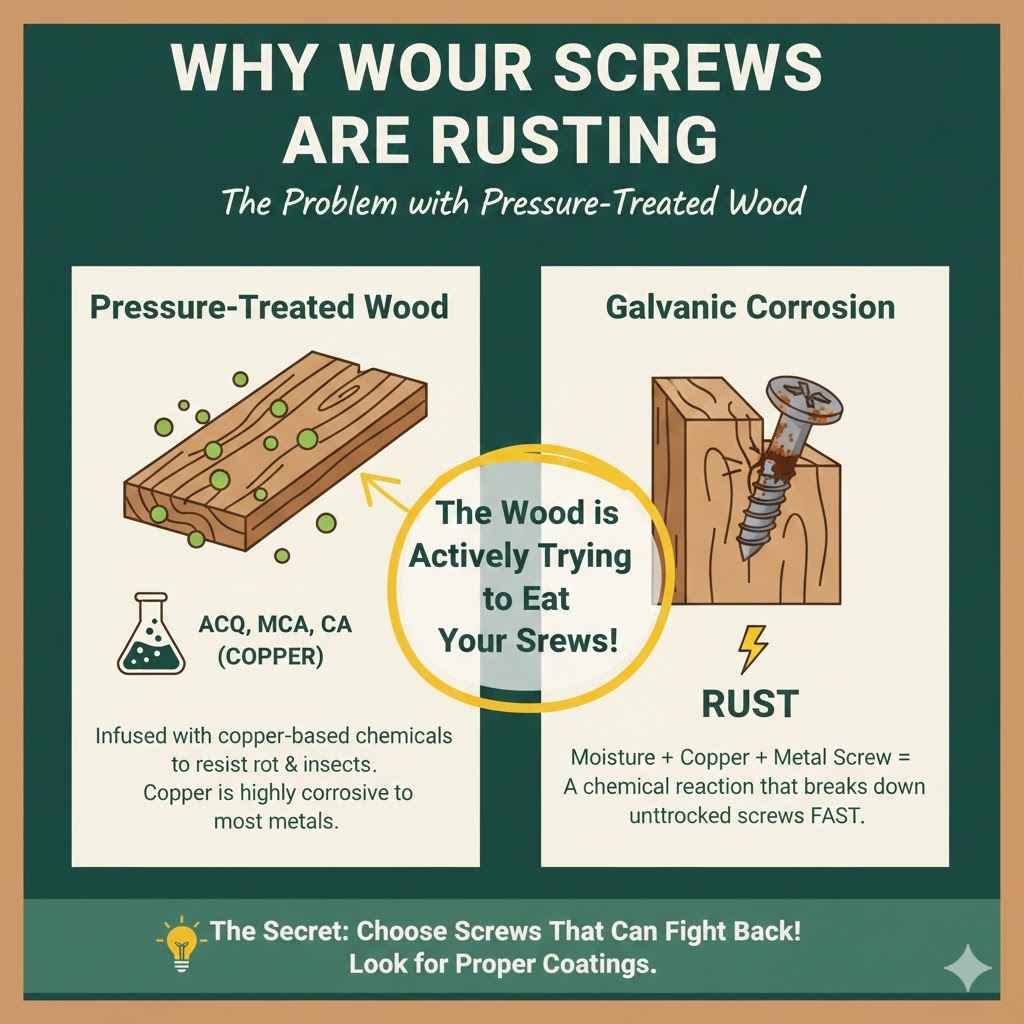

Why Your Screws Are Rusting: The Problem with Pressure-Treated Wood

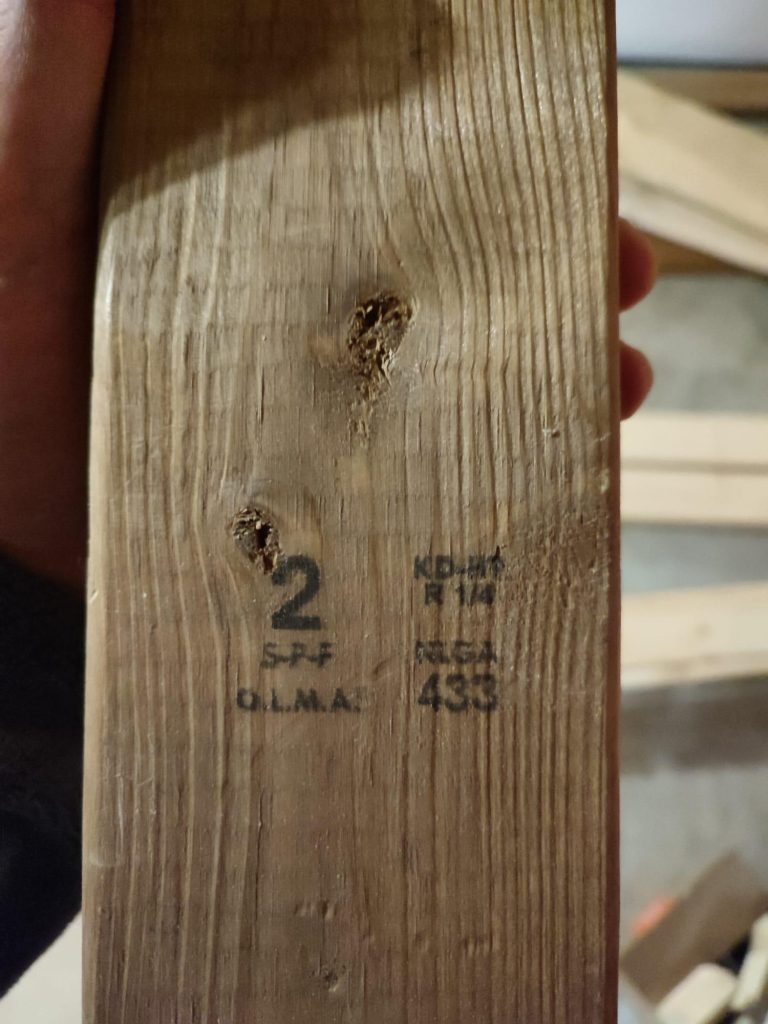

First, let’s understand why pressure-treated wood is so tough on screws. This type of wood is fantastic for outdoor projects because it’s infused with chemicals to resist rot, decay, and insects. For many years, the primary chemical was Chromated Copper Arsenate (CCA). However, due to health concerns, the industry switched to safer alternatives.

Today, most pressure-treated lumber you buy at the home improvement store is treated with chemicals like Alkaline Copper Quaternary (ACQ), Micronized Copper Azole (MCA), or Copper Azole (CA). Do you see the common ingredient? It’s copper.

Copper is excellent for preserving wood, but it’s highly corrosive to most metals. When you drive a plain steel or improperly coated screw into this wood, a chemical reaction called galvanic corrosion begins. Moisture from rain or humidity acts like a battery, causing the screw to rust and break down surprisingly fast. This is why a standard screw that works great indoors will fail quickly outdoors in treated lumber.

Think of it like this: the wood is actively trying to eat your screws. Our job is to choose screws that can fight back.

The Secret Revealed: Meet the Top 3 Screws for Treated Wood

The secret to success isn’t complicated—it’s all about choosing a fastener with a protective shield against corrosion. You have three fantastic, reliable choices. Let’s break them down so you can feel confident at the hardware store.

Choice #1: Hot-Dip Galvanized Screws (The Workhorse)

Hot-dip galvanized screws are the go-to choice for many professional builders, and for good reason. They are made by dipping standard steel screws into a vat of molten zinc. This process creates a thick, durable, and sacrificial coating of zinc that protects the steel underneath.

This zinc coating corrodes very, very slowly, “sacrificing” itself over many years before the copper in the wood can ever reach the steel core of the screw. It’s a tough, affordable, and effective solution for most outdoor projects.

- Pros: Excellent corrosion resistance, strong, widely available, and very affordable.

- Cons: The thick coating can sometimes be a bit rough or clog the threads and driver head. They have a dull, matte gray finish which some people don’t prefer.

- Best For: Decks, fences, framing, retaining walls, and general outdoor construction where function and cost are top priorities.

Choice #2: Stainless Steel Screws (The Premium Pick)

If you want the absolute best protection against rust, stainless steel is the champion. Unlike galvanized screws that rely on a coating, stainless steel has corrosion resistance built right into the metal itself. It’s an alloy of steel, chromium, and other elements that naturally resist rust.

For projects near saltwater, in areas with high humidity, or if you simply want a clean, beautiful finish that will never bleed or stain your wood, stainless steel is worth the investment. You will typically see two grades:

- Grade 305 Stainless Steel: The most common type for general deck building. It offers excellent corrosion resistance for most applications.

- Grade 316 Stainless Steel: This is the marine-grade option. It has added molybdenum for superior corrosion resistance, making it essential for projects near the ocean, pools, or areas exposed to salt spray.

- Pros: Superior, lifelong corrosion resistance. Clean, bright finish. Will not stain the wood.

- Cons: More expensive than galvanized or coated screws. The metal is slightly softer than hardened steel, so it’s important to drive them carefully to avoid stripping the head.

- Best For: High-end decks, docks, projects near saltwater or pools, cedar or redwood projects (which can be stained by other screws), and any job where appearance and maximum longevity are key.

Choice #3: Coated Screws (The Modern All-Rounder)

The third fantastic option is specially coated screws. These aren’t your average painted screws. They are steel screws covered in multiple layers of a proprietary polymer or ceramic coating designed specifically to create a barrier against the corrosive chemicals in treated wood.

These coatings are incredibly tough and are often tested to withstand hundreds or even thousands of hours of salt spray. Many brands sell deck screws that have these advanced coatings. They often come in different colors (like tan, green, or gray) to better match your decking material.

- Pros: Excellent corrosion resistance, available in multiple colors, smooth driving, and often designed with features like self-drilling tips or special thread patterns.

- Cons: The coating can be scratched off during installation if you are not careful, which can create a weak spot for rust to form. Quality can vary between brands, so stick to reputable ones.

- Best For: Decks, fences, playgrounds, outdoor furniture, and any project where you want a combination of great protection and a matching color finish.

Quick Comparison: Which Screw is Right for You?

Feeling a bit overwhelmed by the choices? Don’t worry! This simple table breaks it down for you. Just find what’s most important for your project—cost, protection, or looks—and you’ll have your answer.

| Feature | Hot-Dip Galvanized | Stainless Steel | Coated Screws |

|---|---|---|---|

| Corrosion Resistance | Good to Excellent | Best | Excellent |

| Cost | Low | High | Medium |

| Appearance | Dull, industrial gray | Bright, clean silver | Available in colors |

| Best Use Case | Structural framing, fences | Coastal areas, high-end decks | Visible decking, general outdoor |

Screws You Must Avoid (This is Important!)

Now that you know what to use, it’s just as important to know what to avoid. Using the wrong screw is a guaranteed way to see your project fail. Steer clear of these types:

- Electro-Galvanized or Zinc-Plated Screws: These may look shiny and protected, but the zinc coating is incredibly thin—think of it as a coat of paint versus a thick winter jacket. The copper in treated wood will eat through this coating in a matter of months.

- Drywall Screws: These screws are brittle and have a black phosphate coating that offers zero protection against moisture or chemicals. They will snap under the pressure of wood movement and rust away almost immediately.

- Uncoated Steel Screws: Plain steel screws have no defense at all and will begin rusting on contact with the chemicals in the wood.

Choosing the wrong fastener is not just a cosmetic issue; it’s a safety issue. A deck or railing held together with failed screws is a serious hazard. For more information on wood preservatives and their effects, you can check out resources like the U.S. Forest Products Laboratory, which studies these materials extensively.

Matching the Screw to Your Project: A Simple Guide

Let’s make this super practical. Here is what I recommend for some common DIY projects.

For Decks and Docks (High Moisture)

These projects are constantly exposed to rain, sun, and foot traffic. Don’t cut corners here.

- Best Choice: Stainless Steel Screws. For a deck that will last a lifetime with no rust stains, this is the way to go. Use Grade 316 if you are anywhere near saltwater.

- Good Choice: High-Quality Coated Deck Screws. Choose a reputable brand known for a durable coating. They provide excellent protection and come in colors to match your deck boards.

For Fences and Pergolas (General Outdoor Use)

These projects are vertical, so they shed water better than a deck. They still need solid protection, but you have more flexibility.

- Best Choice: Hot-Dip Galvanized Screws. They provide all the strength and corrosion resistance you need at a great price point. Their industrial look is perfect for structural connections.

- Good Choice: Coated Screws. If you want the screw heads to blend in with your fence pickets or pergola beams, a color-matched coated screw is an excellent option.

For Garden Beds and Playgrounds (Safety and Longevity)

For these projects, safety and long-term stability are critical. You also want to avoid any rust bleeding into the soil of your garden bed.

- Best Choice: Stainless Steel Screws. They are completely inert and will never leach rust into your garden soil. For a playground, they provide the ultimate peace of mind that the structure will remain secure.

- Good Choice: Ceramic-Coated Screws. A high-quality coated screw is a great alternative. The coating provides a strong barrier, and they often feature a smooth head that is less likely to snag clothes or skin.

A Beginner’s Guide to Screw Anatomy

When you look at a box of screws, you might see a lot of terms. Here’s a quick rundown of what they mean for you.

| Part | What It Means | What to Look For |

|---|---|---|

| Head Type | The top of the screw. A “flat head” or “bugle head” is designed to sit flush or slightly below the wood surface. | Most deck screws have a flat head for a clean finish. |

| Drive Type | The shape of the recess your drill bit fits into. Common types are Phillips, Square, and Star (Torx). | Star drive (Torx) is the best for outdoor projects. It provides a much better grip, preventing the bit from slipping and stripping the screw head. |

| Threads | The helical ridges on the screw. Coarse threads are standard for softwood like pressure-treated pine. | Look for screws with coarse threads. Some may have a self-drilling tip to help prevent the wood from splitting. |

Why I Love Star Drive (Torx) Screws

If you take one piece of advice from this section, it’s this: use screws with a star drive head. Unlike the traditional Phillips head that can easily slip and “cam out” (which is what we call it when the bit strips the screw), the star shape provides six points of contact. This gives your drill bit a firm, positive grip, allowing you to drive screws more easily and with more control. It saves a lot of frustration, especially on a big project like a deck.

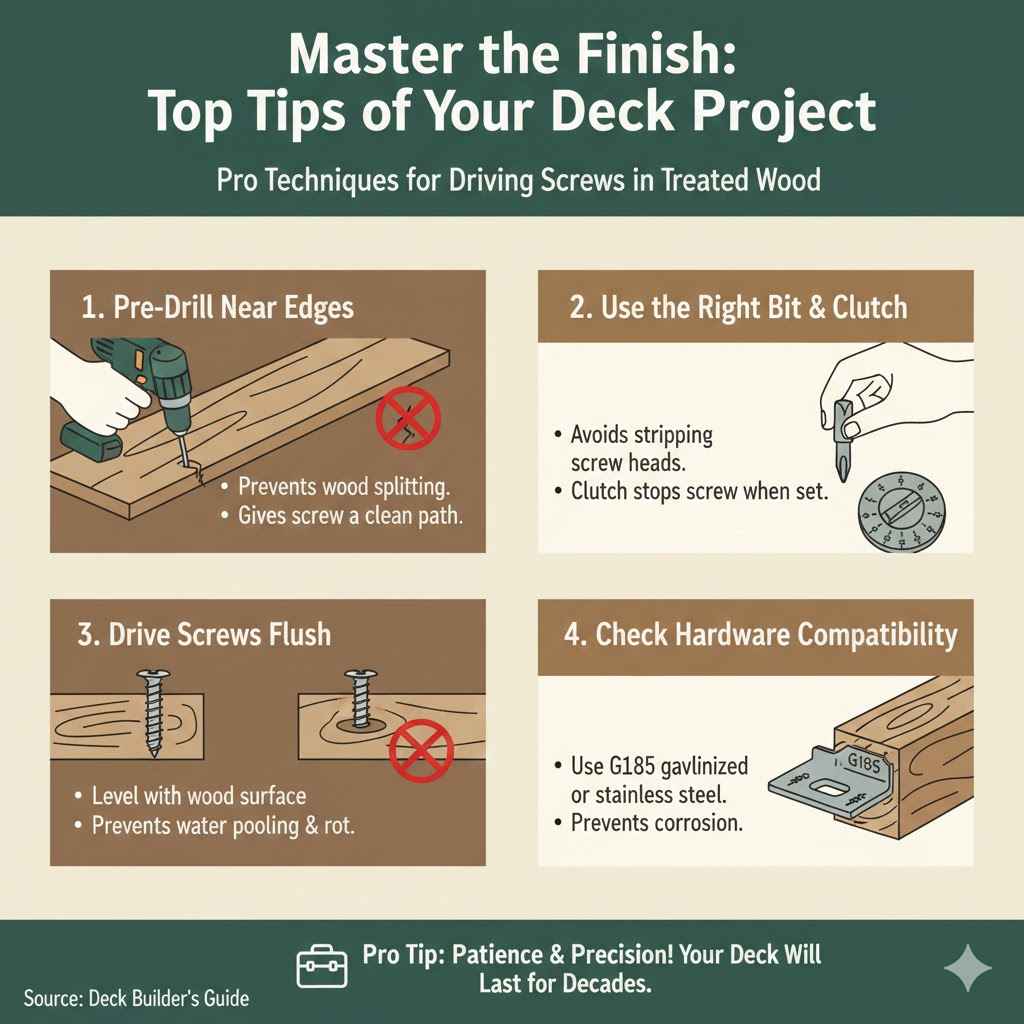

My Top Tips for a Perfect Finish

Choosing the right screw is step one. Using it correctly is step two. Here are a few simple tips to ensure your project looks professional.

- Always Pre-Drill Near Edges: Pressure-treated wood can be prone to splitting, especially when you drive a screw close to the end of a board. Drilling a small pilot hole first gives the screw a clear path and prevents the wood from cracking.

- Use the Right Driver Bit: The box of screws will often come with the correct size star or square driver bit. Use it! Using the wrong size is the fastest way to strip a screw head.

- Set Your Drill’s Clutch: Your drill has a numbered ring behind the chuck. This is the clutch. Set it to a medium number to start. This will stop the screw from turning once it’s driven in, preventing you from driving it too deep and damaging the wood fiber.

- Drive Screws Flush, Not Too Deep: The bottom of the screw head should be level with the surface of the wood. If you drive it too deep, you create a small crater where water can pool, which can lead to rot over time.

- Check Hardware Compatibility: If you are using metal hardware like joist hangers or post bases, make sure they are also rated for pressure-treated wood (usually labeled G185 galvanized). Never use standard galvanized hardware with stainless steel screws, as it can accelerate corrosion.

Frequently Asked Questions (FAQ)

Can I use regular deck screws in pressure-treated wood?

It depends. If the box specifically says the screws are approved for use with pressure-treated wood (ACQ, etc.), then yes. If they are just generic “deck screws” with a basic zinc plating or a thin coating, then no. Always check the packaging for compatibility.

What’s the difference between hot-dip galvanized and zinc-plated screws?

The thickness of the coating. Hot-dip galvanizing creates a very thick, durable layer of zinc that provides long-term protection. Zinc-plating (electro-galvanizing) is a very thin, cosmetic layer that will corrode away quickly in treated wood.

Are stainless steel screws worth the extra cost?

For certain projects, absolutely. If your project is in a high-moisture environment, near a coast, or if you want a perfect, stain-free finish that will last for decades, the extra cost of stainless steel is a wise investment in longevity and peace of mind.

Do I need to pre-drill holes for these screws?

It is always a good practice, especially when working within an inch or two of a board’s end. Many modern coated screws have self-drilling tips that reduce the need for pre-drilling in the middle of a board, but it never hurts and is the best way to prevent splitting.

How long do coated screws last?

This depends on the quality of the coating and the environment. High-quality ceramic or polymer-coated screws from reputable brands are designed to last for the life of the wood project, often carrying a limited lifetime warranty against corrosion.

What happens if I use the wrong screws?

First, you will see ugly black or orange rust streaks staining the wood around the screw head. Over time, the screw will corrode and weaken. In a structural application like a deck or railing, this will eventually lead to a dangerous failure of the connection.

Can I use nails instead of screws?

You can, but screws provide much greater holding power and make it easier to disassemble or repair the project later. If you do use nails, they must also be rated for pressure-treated wood—look for hot-dip galvanized or stainless steel nails.

Conclusion: Building with Confidence

And there you have it—the secret is out! Choosing the best screws for pressure-treated wood is all about fighting corrosion. By selecting either hot-dip galvanized, stainless steel, or a quality coated screw, you are giving your project the protection it needs to stand strong against the elements for many, many years.

You don’t need to feel confused in the hardware store aisle anymore. Think about your project, your budget, and the look you want to achieve, and you can choose with complete confidence. Now you have the knowledge to build it right the first time. Go ahead and start that project you’ve been dreaming of. You’ve got this!