How Long To Let Mineral Spirits Dry: Essential Secrets

Mineral spirits usually dry in 24 to 72 hours, but the actual drying time depends heavily on temperature, humidity, airflow, and the amount used. For best results before painting or staining, ensure the surface is completely dry to the touch, often requiring a full 24 hours in ideal workshop conditions.

Welcome, fellow DIYer! Dealing with finishes and cleaning solvents can sometimes feel tricky, especially when you are waiting for things to dry. Mineral spirits are fantastic for thinning finishes, cleaning brushes, or prepping wood surfaces. But knowing exactly how long to wait before moving to the next step is the secret to avoiding sticky spots or ruined projects. If you have ever rushed the drying process only to find your varnish won’t cure right, you are not alone!

Don’t worry; getting this timing right is easier than you think. We will walk through the simple steps and essential secrets that guarantee your wood is perfectly dry and ready for its beautiful new coat. Let’s dive into achieving that smooth, professional finish every time.

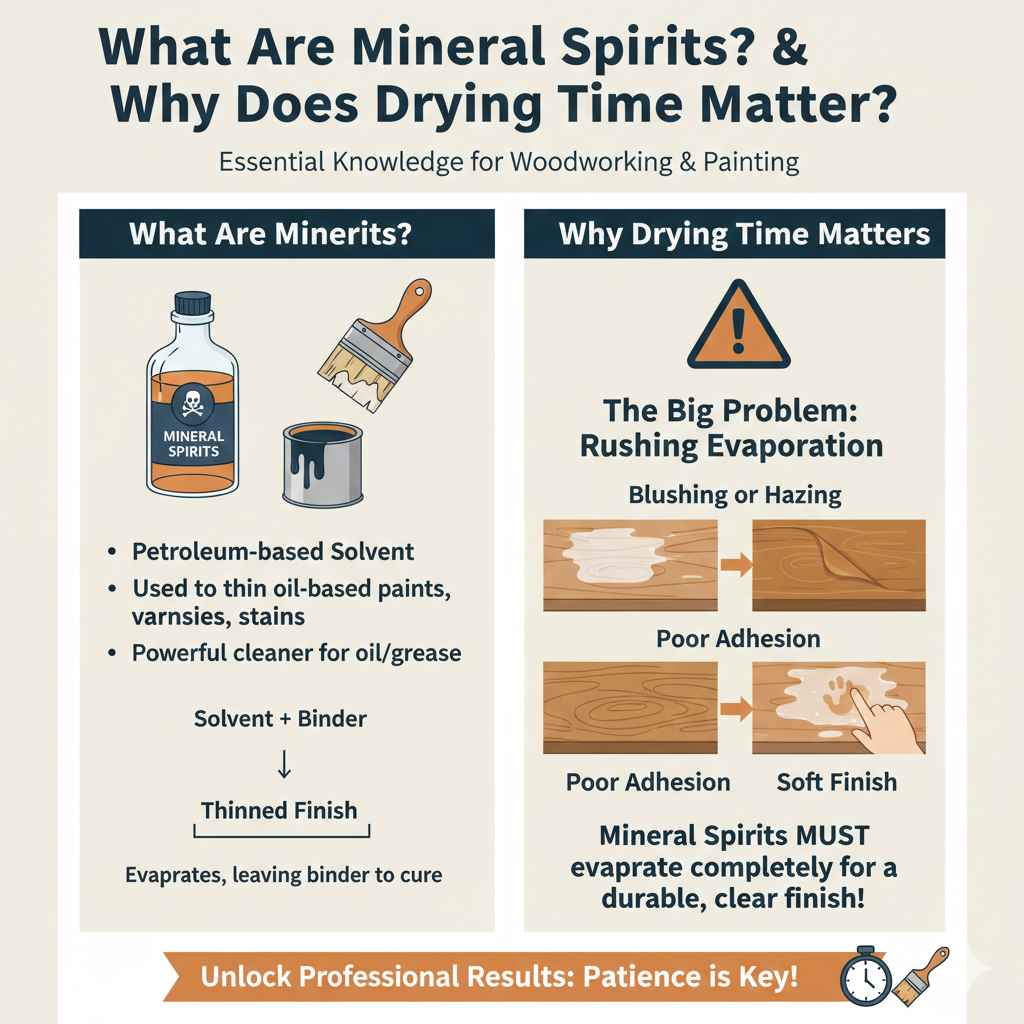

What Are Mineral Spirits, and Why Does Drying Time Matter?

Before we talk time, let’s quickly remember what mineral spirits are. They are a common, petroleum-based solvent. In woodworking and painting, we use them mostly for thinning oil-based paints, varnishes, and stains, or as a powerful cleaner for oil residue.

They work by dissolving binders in those oil-based products. When you apply a thinned finish, the mineral spirits must evaporate completely so the binder (the part that actually sticks to the wood and hardens) can cure properly.

The Big Problem: Rushing the Evaporation

If you try to paint, stain, or seal wood too soon after using mineral spirits—whether for cleaning or thinning—you run into trouble. The solvent gets trapped under the new layer of finish. This leads to several frustrating issues:

- Blushing or Hazing: The finish looks cloudy instead of clear.

- Poor Adhesion: Your new coat won’t stick well and can peel off later.

- Soft Finish: The final surface stays tacky or soft, taking weeks to fully harden.

Understanding the drying time is key to unlocking professional-looking results right in your workshop.

The Typical Drying Time for Mineral Spirits

This is the question everyone asks! While there is no single answer carved in stone, we can give you reliable ranges based on typical use. Remember, mineral spirits are volatile, meaning they evaporate, but “volatile” doesn’t mean instant!

Drying Time Based on Use Case

The time needed changes drastically depending on how you used the mineral spirits:

- As a Thinner for Oil-Based Finishes: If you mixed a small amount into paint or varnish, the drying time is often dictated by the finish itself. Most manufacturers suggest waiting 24 hours for recoating, even if the spirits seem gone faster.

- As a Cleaner on Wood Surfaces: If you wiped down wood to remove wax or dirt before staining, you need the surface completely dry. In good conditions, this can take as little as 1 hour, but 4 to 6 hours is much safer.

- As a Finish Remover (Stripper): When used heavily to strip old paint, the soaking process traps a lot of solvent. You must allow ample time—often 48 to 72 hours—to ensure deep evaporation.

The Five Core Factors That Control Drying Speed

This is where we unlock the “essential secrets.” Drying is not just about the clock; it’s about the environment surrounding the treated surface. Here are the five biggest game-changers for how fast those spirits vanish.

1. Airflow and Ventilation (The Most Critical Factor)

Solvents need fresh, dry air to move in and carry the vapor away. Stagnant air traps the solvent vapor right near the surface, slowing evaporation dramatically.

- Good Airflow: Using fans, opening windows, or working outdoors significantly speeds drying. Think of it like blowing steam away from a mirror after a shower.

- Poor Airflow: A closed closet or a damp garage with no circulation can keep mineral spirits wet for days.

2. Temperature Matters

Heat provides energy for molecules to escape into the air faster (evaporation).

- Warmer Temps (70°F – 80°F): Ideal range for quick evaporation.

- Cooler Temps (Below 60°F): Drying slows down considerably. Cold air just doesn’t hold solvent vapor as well.

3. Humidity Levels

High humidity is the enemy of evaporation. When the air is already saturated with water vapor, it has less capacity to accept new vapor (the mineral spirits).

If humidity is above 70%, drying will be noticeably slower, even with good airflow. If you are in a humid climate, plan for at least double the drying time.

4. Application Thickness

This is simple physics. A thin, wiped-on layer evaporates much faster than a thick puddle.

- If you are cleaning, use just enough to wet the rag, not saturate the wood.

- If thinning finish, use the least amount necessary. Less solvent means faster drying.

5. Substrate Porosity

The wood itself plays a role. Highly porous woods (like raw pine or open-grain oak) absorb the spirit deeper than dense woods (like maple or cherry). The spirits trapped deep inside take longer to work their way out to the surface to evaporate.

Step-by-Step Guide: Ensuring Complete Dryness Before Staining

For our target audience—the DIY homeowner—the most common use for mineral spirits is prepping wood before applying a new coat of stain or paint. Getting this prep phase right saves hours of frustration later.

Here is the foolproof process, focusing on “how long to let mineral spirits dry before staining”:

Phase 1: Preparation and Cleaning

Assume you just wiped down your wood to remove sanding dust, grease, or old wax using mineral spirits.

- Wipe Lightly: Apply the mineral spirits to a clean rag, not directly onto the wood. Wipe the surface quickly and evenly.

- Wipe Off Residue: Immediately follow up with a second, clean, dry rag to remove any lingering moisture or residue. You want to use as little as possible.

- Maximize Airflow: Place a fan directed across the surface, not directly down onto it. Open windows if possible.

Phase 2: Waiting and Testing (The Crucial Waiting Period)

Even in great conditions, always buffer your time. If you think it will take 2 hours, wait 4.

The Time Benchmark Table

Use this table as a starting guide for mineral spirits used as a light cleaner (not a thick coating):

| Environmental Condition | Minimum Safe Wait Time (Before Staining) | Ideal Wait Time |

|---|---|---|

| Warm (75°F) & Low Humidity (<50%) | 2 Hours | 4 Hours |

| Room Temperature (68°F) & Moderate Humidity (55-65%) | 4 Hours | 6-8 Hours |

| Cool (70%) | 8 Hours | 24 Hours |

Phase 3: The Touch Test (The Only True Indicator)

Never rely only on the clock. You must perform a touch test before applying your stain or topcoat.

- The Feel Test: Gently touch an inconspicuous area of the wood. It should feel completely dry, not cool, damp, or slightly tacky.

- The Smudge Test (Use Caution): Rub your clean, dry finger firmly across a section of the wood. If any residue or stickiness transfers to your finger, the solvent has not evaporated. Wipe it again with a clean rag and wait longer.

- The Smell Test: You should not strongly smell the sharp odor of mineral spirits anymore. A very faint scent is okay, but strong odors mean the vapors are still present.

Mineral Spirits as a Finish Thinner: When to Re-coat

This scenario requires a slightly different approach because you are dealing with two components drying simultaneously: the spirit and the finish (like alkyd paint or oil varnish).

Understanding Viscosity vs. Evaporation

When you thin varnish, the goal is to reduce its thickness (viscosity) so it flows better. You often need the paint film to be “set up” but not fully dry before the next layer goes on.

Check the technical data sheet (TDS) for your specific paint or varnish. Most oil-based finishes recommend recoating times based on specific factors:

- Dry to the touch: Usually 4–12 hours.

- Recoat Window: The time frame where the previous layer is firm enough to accept a new layer without lifting or wrinkling. For many oil paints, this is often within 24 hours.

Md Meraj’s Expert Tip for Thinned Finishes: If you thinned your oil-based product heavily (more than 15% thinner), increase your wait time between coats by 50%. Trapped mineral spirits are the number one cause of soft, sticky oil finishes.

Safety First: Handling and Disposal of Used Spirits

We need to talk about safety, friends. Mineral spirits are flammable, and improper drying or disposal can be dangerous. This isn’t directly about drying time on the wood, but it’s essential for responsible DIY work.

Ventilation for Health

Always ensure good ventilation not just for drying speed, but for your health. Mineral spirit fumes are unpleasant and can cause headaches or dizziness if inhaled too long.

The Environmental Protection Agency (EPA) notes that proper ventilation helps reduce Volatile Organic Compounds (VOCs) released into your immediate work area, improving air quality. (Source: EPA guidelines on solvent usage).

Storing Used Spirits

Do not just pour used mineral spirits down the drain or into the trash if they have paint or heavy residue.

- Settle Out: Pour used spirits into a sealable, non-reactive metal container (like an old paint can with a tight lid). Let it sit for several weeks or months in a safe, dry area away from heat sources. The solids (paint sludge) will sink to the bottom.

- Reuse or Dispose: The relatively clean liquid on top can often be carefully decanted and reused for cleaning brushes later. The sludge at the bottom must be disposed of according to your local hazardous waste guidelines. Never mix large amounts of solvent waste with regular garbage.

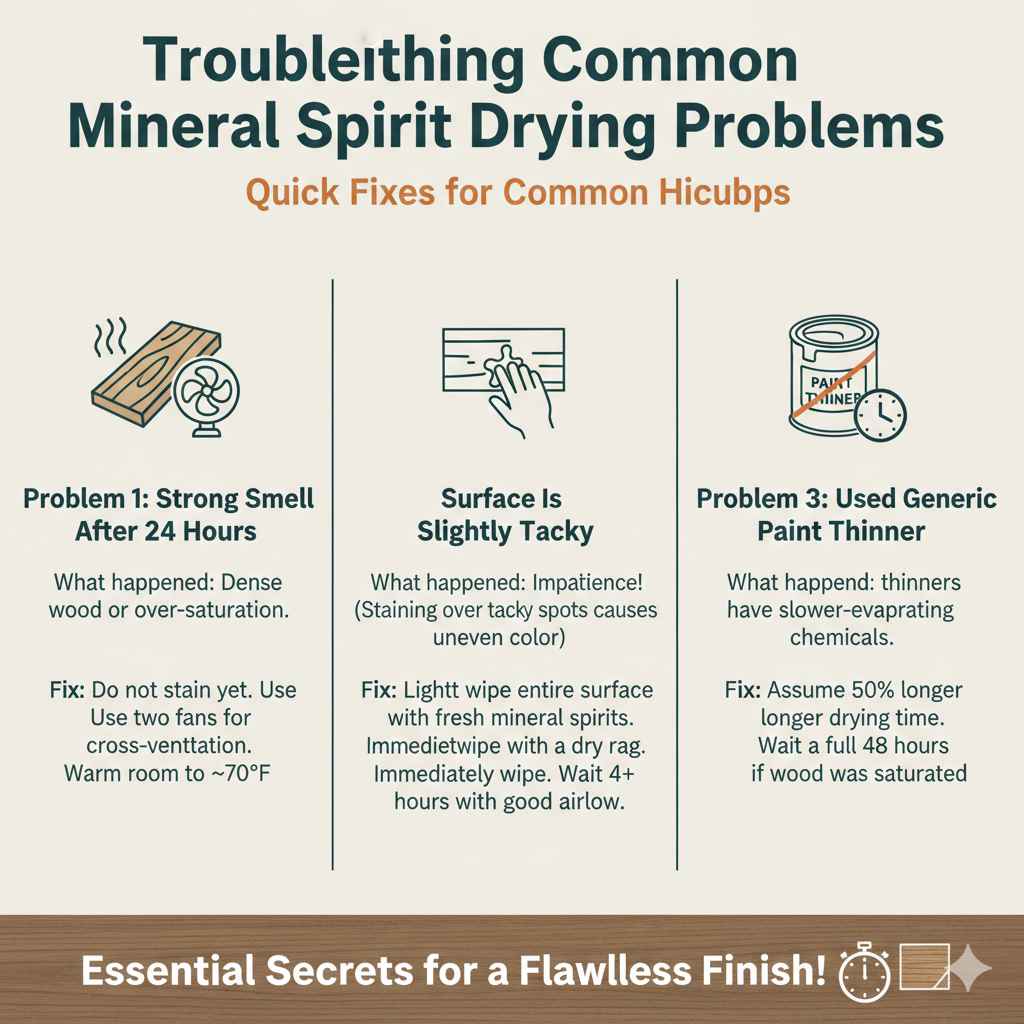

Troubleshooting Common Mineral Spirit Drying Problems

Even when you try to be patient, sometimes things don’t dry as expected. Here are quick fixes for common hiccups.

Problem 1: The Wood Still Smells Strongly After 24 Hours

What happened: The wood is very dense, or you used too much spirit, soaking deep into the grain.

The Fix: Do not stain yet. Introduce forced, warm air. Set up two fans—one blowing air across the surface and another pulling the air out of the room (creating cross-ventilation). If possible, slightly warm the room (aiming for 70°F).

Problem 2: My Surface is Slightly Tacky, But I Need to Finish Today

What happened: You’re impatient (and I understand!), but staining over tacky areas will result in an uneven, patchy color.

The Fix: If the tackiness is light, you can try wiping the entire surface down one last time with a rag lightly dampened with fresh mineral spirits. This brief re-wetting can sometimes help redistribute the remaining solvent, allowing it to flash off faster when combined with good airflow. Wipe immediately with a dry rag, then wait at least 4 more hours before testing again.

Problem 3: I Used Paint Thinner (Not Pure Spirits)

What happened: Paint thinners (like lacquer thinner or hardware store “paint thinner”) often contain stronger, slower-evaporating chemicals than pure VM&P naphtha or Stoddard solvent (what most woodworkers call mineral spirits).

The Fix: If you used a generic “paint thinner,” assume the drying time is extended by 50% compared to pure mineral spirits. Wait a full 48 hours if you saturated the wood during cleaning.

FAQs for Beginner Woodworkers

Here are some common questions you might have when dealing with this solvent.

Q1: Can I speed up mineral spirit drying with a heat gun?

A: No, absolutely not. Heat guns can cause the mineral spirits to boil rapidly, potentially causing small flare-ups, and more importantly, they can quickly drive the solvent deeper into the wood rather than helping it evaporate.

Q2: How long do I wait to paint over a surface cleaned with mineral spirits?

A: For oil-based paints, wait until the wood is dry to the touch, generally 4 to 6 hours under good airflow. For water-based paints, you must be extremely cautious. Wait at least 8 to 12 hours, as water-based topcoats do not play well with residual petroleum solvents.

Q3: Is it safe to use acetone or denatured alcohol instead of mineral spirits to speed up drying?

A: You can use a faster solvent like naphtha or acetone to “chase” the mineral spirits out, but this must be done carefully. Apply a very small amount to a clean rag and wipe down the surface, then immediately follow with a dry rag. These chemicals evaporate much faster, carrying some of the slower-evaporating spirits with them. However, they are far more aggressive and require excellent ventilation.

Q4: What is the difference between “mineral spirits” and “paint thinner”?

A: Mineral spirits (or Stoddard solvent) are a specific grade of petroleum distillate. “Paint thinner” is a general term. Some paint thinners are just mineral spirits, while others contain stronger, faster-evaporating, or residue-leaving chemicals. Always check the label for the purest option if fast drying is your goal.

Q5: If the wood feels dry but smells a little, is it okay to stain?

A: If you are staining with an oil-based stain, a little faint odor is usually okay, but for best results, wait until the smell is almost gone. If you are using a water-based gel stain, wait until the odor is completely gone, as the water in the gel stain can react poorly with the trapped petroleum vapors.

Q6: Do I need to seal the wood after cleaning with mineral spirits but before staining?

A: No sealing is necessary or recommended. The entire point of cleaning with mineral spirits before staining is to ensure the wood pores are open and clean so the stain absorbs evenly. Adding a sealant now will just block the stain from doing its job.

Final Thoughts on Patience and Perfection

We’ve covered the environmental conditions, the essential touch tests, and the specific scenarios for thinning versus cleaning. Remember, achieving that professional, long-lasting wood finish doesn’t come from speeding up the clock—it comes from respecting the chemistry of evaporation.

Mineral spirits need time for the environment to pull the vapors away from the wood surface. By prioritizing good airflow, maintaining a moderate temperature, and always performing the touch and smell tests, you are ensuring that when you finally apply that beautiful stain or varnish, it adheres perfectly and cures hard, not sticky. Confidence in your project comes from knowing you didn’t cut corners. Go ahead, set up that fan, grab a cup of coffee, and give your project the time it deserves. You’ll be rewarded with a finish you can be truly proud of!