How Much Does a Small Poolside Wood Deck Cost

Wondering How Much Does a Small Poolside Wood Deck Cost? It’s a question many homeowners ask when planning to spruce up their backyard oasis. Figuring out the price can feel a bit tricky, especially if you’re new to home improvement projects. But don’t worry!

We’ll break it all down simply, step by step. Get ready to see how easy it is to get a clear picture of your deck project’s budget. We’ll guide you through what makes the price go up or down so you can plan with confidence.

Understanding Small Poolside Wood Deck Expenses

When you’re thinking about adding a small wood deck next to your pool, knowing the cost upfront is super helpful. This section will look at the different parts that add up to the total price. It covers everything from the wood itself to how much labor you might need.

We’ll help you see what goes into the final number so you can budget smartly for your dream poolside space. This guide aims to make the cost of a small poolside wood deck clear and easy to grasp, even if you’ve never built a deck before.

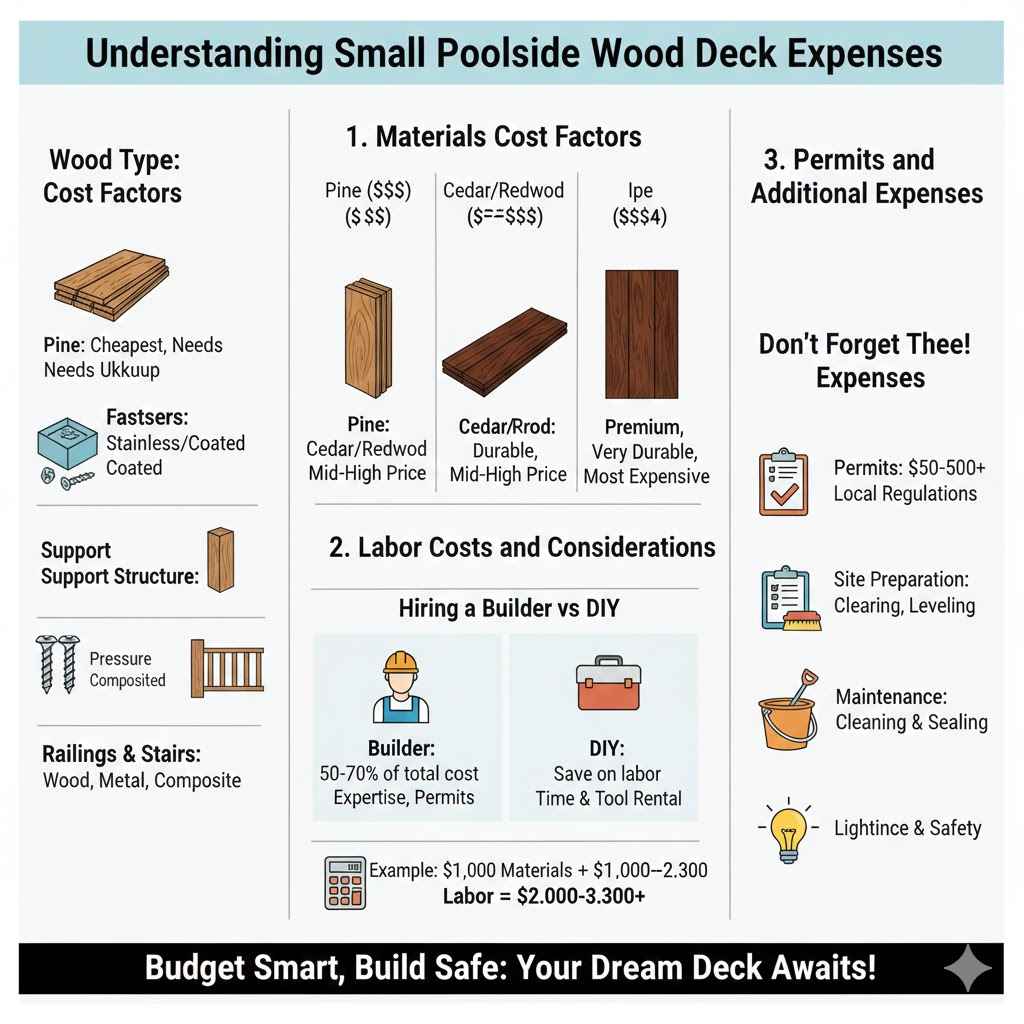

Materials Cost Factors

The type of wood you choose is a big deal for your budget. Cedar and redwood are lovely and resist rot well, but they cost more. Pine is a cheaper option, but it needs more upkeep to last.

You’ll also need to think about fasteners like screws and nails, support posts, and any concrete for the footings. Don’t forget about deck boards, railings, and any stairs or steps. Each of these adds to the overall price tag of your small poolside wood deck.

-

Wood Type: Different woods have different prices. Softwoods like pine are usually the cheapest. Hardwoods like Ipe are very expensive but last a long time.

Pressure-treated lumber offers a good balance of cost and durability for many applications.

- Fasteners: Screws and nails hold your deck together. Using stainless steel or coated fasteners is important to prevent rust, especially near a pool. These specialized fasteners can cost a bit more than standard ones.

- Support Structure: The posts and beams that hold up your deck need to be strong and rot-resistant. Pressure-treated wood is common here. The depth and spacing of these supports depend on local building codes and the size of your deck.

- Railings and Stairs: If your deck is raised or you want safety, you’ll need railings. These can be made from wood, metal, or composite materials. Stairs also add to the material cost, depending on their width and design.

For instance, a basic 10×10 foot deck using pressure-treated pine might cost around $500 to $1,000 for just the lumber and fasteners. If you choose a premium wood like cedar for the same size deck, the lumber cost could jump to $1,500 to $3,000 or more.

Labor Costs and Considerations

Hiring professionals to build your deck will add significantly to the total cost. The hourly rates for deck builders can vary a lot by location and experience. A complex design or difficult site conditions can also increase labor hours.

If you’re a DIYer, you’ll save money on labor but need to factor in your time and any tools you might need to buy or rent.

A general rule of thumb is that labor can account for 50% to 70% of the total project cost for a deck installation. For a small poolside wood deck, this means if your materials cost $1,000, labor could add another $1,000 to $2,300. This figure can change based on how much work is involved, like if you need to clear the land or have tricky access to the pool area.

Even for a small deck, the skill of the builder matters. Proper attachment to the house (if applicable), correct footing depth, and secure railing installation are vital for safety and longevity. A good builder ensures your deck meets local building codes, which can prevent costly repairs or removals later.

Consider these points for labor:

- Builder Experience: Experienced deck builders often charge more per hour but can work faster and more efficiently. They also bring expertise that can prevent mistakes.

- Project Complexity: A simple, ground-level deck will cost less in labor than a multi-level deck or one with intricate designs. Building around existing pool features can also add time.

- Permits: Some areas require permits for deck construction. The cost of obtaining these permits is usually separate from labor but can be managed by the contractor.

- Site Preparation: If the area needs to be cleared, leveled, or excavated, this will add to the labor costs. Easy access to the work area can reduce labor time.

Permits and Additional Expenses

Before you start building, check if you need a permit from your local city or county. Permit fees vary but are usually a small percentage of the total project cost. Ignoring permits can lead to fines and the requirement to dismantle your deck.

Other costs to consider include:

- Site preparation: Clearing brush, leveling the ground, or removing old structures adds to the cost.

- Deck cleaning and sealing: To keep your wood deck looking good and lasting longer, you’ll need to clean and seal it periodically. This is an ongoing cost.

- Lighting: Adding deck lighting for evening ambiance and safety can increase the initial investment but enhances usability.

For example, permit fees can range from $50 to $500 or more, depending on your location and the project’s scope. These are often a necessary step to ensure your deck is built to code and safely integrated into your property.

Calculating the Cost of a Small Poolside Wood Deck

Now that we’ve looked at the different cost categories, let’s put it all together. We’ll explore how to estimate your budget for a small poolside wood deck. This involves looking at common sizes and material choices to give you a clearer picture.

Think of this as building your personalized cost estimate, piece by piece, so you know what to expect before you hire anyone or buy materials.

Estimating Based on Size and Material

The size of your deck is the most obvious factor influencing cost. A 10×10 foot deck is quite small and good for a limited space. A 12×12 foot deck offers a bit more room.

The material choice, as discussed, also plays a huge role. Let’s look at some rough estimates for a small deck, say 100 to 150 square feet.

| Deck Size (Sq Ft) | Basic Pressure-Treated Pine (Materials Only) | Mid-Range Cedar (Materials Only) | Premium Hardwood (Materials Only) | Estimated Labor (50-70% of Materials) | Total Estimated Cost (Materials + Labor) |

|---|---|---|---|---|---|

| 100 (e.g., 10×10) | $500 – $1,000 | $1,500 – $3,000 | $3,000 – $6,000+ | $500 – $2,100 | $1,000 – $8,100+ |

| 150 (e.g., 10×15) | $750 – $1,500 | $2,250 – $4,500 | $4,500 – $9,000+ | $750 – $3,150 | $1,500 – $12,150+ |

These are just estimates, and prices can change based on your location, the specific products you choose, and current market conditions. For example, a 10×10 foot deck made from pressure-treated pine with professional installation could realistically range from $1,500 to $3,100. On the other hand, a similar-sized deck made from Ipe hardwood could cost upwards of $6,000 for materials alone, with labor potentially adding another $3,000 to $4,200.

DIY vs. Professional Installation

Deciding whether to build it yourself or hire a pro is a major cost factor. A DIY approach can save you a lot on labor costs, which, as we’ve seen, can be a large portion of the total price. However, it requires your time, effort, and possibly the purchase or rental of tools you don’t already own.

You also need to be comfortable with construction tasks and understand building codes.

A professional installation will likely cost more upfront, but it comes with the benefit of expertise and often a warranty on the work. Professionals can also complete the project much faster than most DIYers. They are familiar with local building regulations and can navigate the permit process smoothly.

Let’s consider a 100 sq ft deck. If materials cost $800:

- DIY Cost: You would only pay for the materials ($800) plus any tool rentals or purchases. If you rent tools for a weekend, this might add $100 to $300. So, your total could be around $900 to $1,100.

- Professional Installation Cost: Labor might be $1,000 to $2,100 for this size deck. Add the material cost ($800), and your total comes to $1,800 to $2,900.

This example clearly shows the potential savings of doing it yourself, but it also highlights the value a professional brings in terms of speed and guaranteed quality.

Geographic Location Impact

Where you live has a significant impact on deck building costs. Labor rates are typically higher in urban areas or regions with a higher cost of living. The availability of specific materials can also affect prices.

For instance, certain types of wood might be more readily available and cheaper in one region than another.

Building material costs can also fluctuate based on regional demand and shipping expenses. Some areas might also have stricter building codes or environmental regulations, which can increase the complexity and cost of construction. This means that a small poolside wood deck that costs $2,000 in one state might cost $3,000 or more in another.

For example, in a high-cost-of-living area like California or New York, you might pay 20-30% more for both materials and labor compared to a more rural area in the Midwest. This geographical price difference is why getting local quotes is always essential.

Factors Influencing Your Poolside Deck Budget

Beyond the basic size and material, several other elements can influence how much your small poolside wood deck ends up costing. Understanding these factors will help you make informed decisions and manage your budget effectively. We’ll explore design choices, existing site conditions, and the importance of quality materials for long-term value.

Design Complexity and Features

A simple, square deck is the most budget-friendly option. However, if you want curves, multiple levels, built-in seating, or custom railing designs, the costs will rise. Features like planters, lighting integration, or even a pergola over part of the deck add both material and labor expenses.

For instance, a deck with a simple straight edge might use standard decking boards laid parallel. A deck with a curved edge requires cutting many boards to a specific arc, which takes more time and material waste. Built-in benches can save on the cost of separate furniture, but they add to the deck’s construction complexity and material needs.

Consider these design elements:

- Shape: Rectangular or square decks are easiest and cheapest. Complex shapes, curves, or angles increase labor and material costs due to more cuts and waste.

- Levels: A single-level deck is less expensive than a multi-level design, which requires more structural support and framing.

- Built-in features: Benches, planters, or even storage compartments add to the material and labor costs of the deck itself.

- Railing style: Basic wooden pickets are cheaper than decorative metal balusters, glass panels, or cable railing systems.

A basic 10×10 deck with simple railings might cost $1,500 to $3,000 installed. Adding features like a curved edge, built-in seating, and custom lighting could push that price to $4,000 or even $6,000 or more for the same size area.

Site Conditions and Preparation

The ground where you plan to build your deck can significantly affect costs. If the area is sloped, you’ll need more extensive foundation work, including deeper footings or retaining walls, to create a level surface. Clearing dense vegetation, removing old structures like patios or sheds, or dealing with poor soil conditions will add to the preparation time and expense.

Access to the site is also critical. If the build area is far from the street or has difficult terrain, contractors may need to charge more for hauling materials and equipment. This logistical challenge can translate into higher labor costs as the crew spends more time moving things around.

Here’s how site conditions can impact costs:

- Slope: A significant slope requires more complex foundation work, potentially involving specialized footings or knee walls, increasing material and labor expenses.

- Existing Structures: Removing an old patio, concrete slab, or debris adds labor time and disposal costs. This can range from a few hundred to over a thousand dollars.

- Soil Type: Poor soil stability may require deeper footings or specific soil amendments, impacting foundation costs.

- Access: Limited access for equipment and material delivery can increase labor time and costs significantly.

For example, if your backyard slopes heavily, the cost for footings and framing for a 100 sq ft deck could double compared to a flat, easily accessible area. You might spend an extra $500 to $1,000 just on foundation adjustments.

Quality of Wood and Hardware

Choosing higher-quality materials often means a higher upfront cost but results in greater durability and longevity. For a poolside deck, resistance to moisture, UV rays, and chemicals from the pool is crucial. Investing in better wood and hardware can save you money on repairs and replacements down the line.

For example, while standard pine is affordable, it’s more prone to rot and insect damage. Pressure-treated pine offers better protection, and hardwoods like Ipe or Teak provide exceptional durability and natural resistance, albeit at a much higher price point. Similarly, using stainless steel fasteners instead of galvanized ones prevents rust stains and ensures structural integrity for years, especially in a humid, chlorine-rich pool environment.

Here’s a look at material quality impact:

- Wood Longevity: Cheaper woods might need

- Maintenance Requirements: Some woods require more frequent sealing and staining than others. Cheaper woods might need annual maintenance, while others can go longer between treatments.

- Hardware Durability: Using stainless steel or high-quality coated screws and nails prevents corrosion and staining, which is vital near a pool. This can add 10-20% to hardware costs but is often worth it.

- Warranty: Reputable material suppliers and manufacturers often offer warranties on their products. A longer warranty can provide peace of mind and indicate a higher-quality product.

For a 100 sq ft deck, upgrading from basic galvanized fasteners to stainless steel might cost an extra $50 to $100. However, this prevents potential rust issues that could stain the wood and weaken the connections over time.

Maximizing Value and Long-Term Savings

Getting the best value for your money on a small poolside wood deck means looking beyond the initial price. It’s about making smart choices that ensure your deck looks great and lasts for many years. This section will offer practical tips to help you save money without compromising quality, focusing on smart material selection and good maintenance practices.

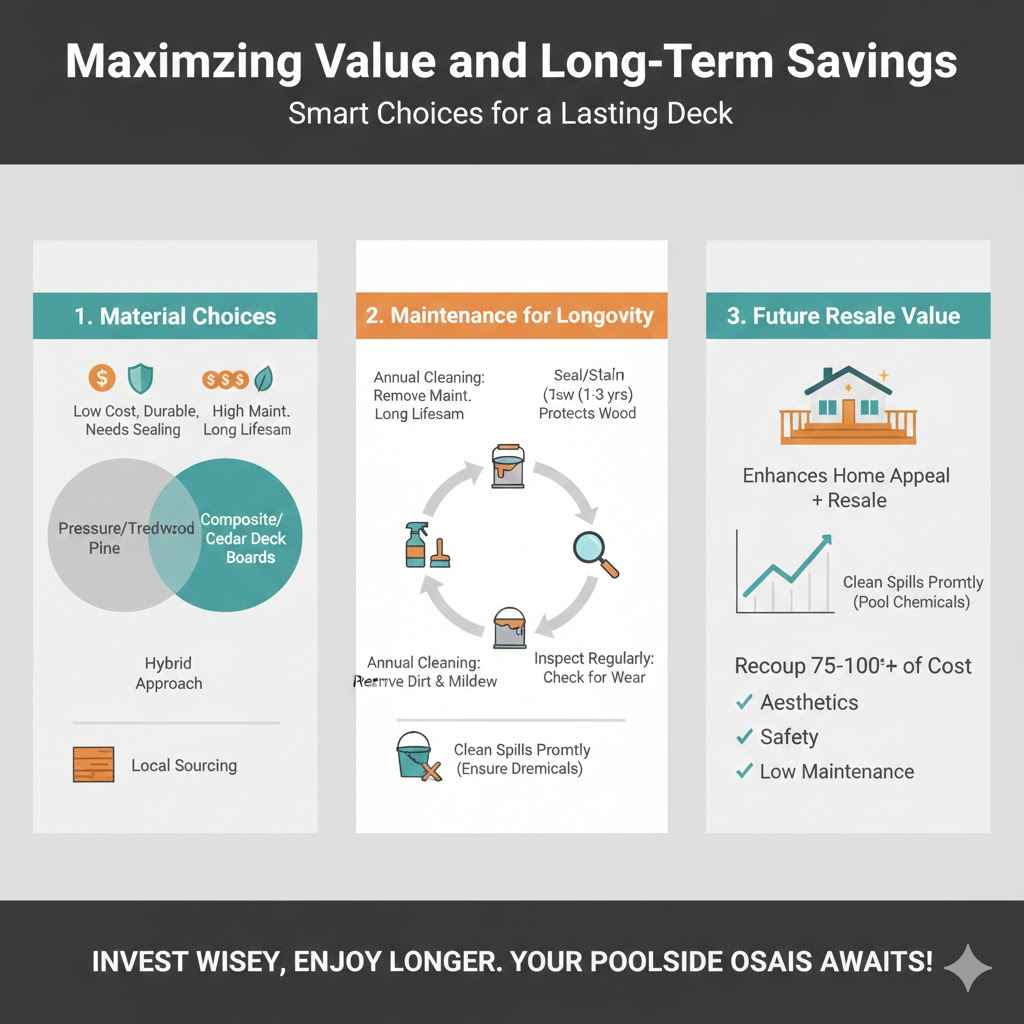

Choosing Cost-Effective Yet Durable Materials

Pressure-treated lumber is often the sweet spot for cost and durability for decks. It’s treated to resist rot, decay, and insects, making it a good choice for outdoor structures. While not as naturally beautiful as cedar or redwood, it can be stained or painted to achieve a desired look.

For a small poolside deck, using pressure-treated wood for the substructure (joists, beams, posts) and a more attractive, but still affordable, wood like cedar for the deck boards themselves can be a smart compromise.

Another option is composite decking, which is made from a blend of wood fibers and plastic. While the upfront cost of composite can be higher than natural wood, it requires very little maintenance and is highly resistant to rot, warping, and fading. This can lead to significant savings on upkeep and replacement costs over the lifespan of the deck.

Consider these material strategies:

- Hybrid Approach: Use pressure-treated wood for the hidden structure and a more aesthetically pleasing wood for the visible surfaces. This balances cost and appearance effectively.

- Engineered Wood Products: Some engineered wood products offer enhanced durability and stability at a competitive price point compared to traditional hardwoods.

- Composite Decking: While a higher initial investment, composite decking can offer excellent long-term value due to its low maintenance and high durability, especially in harsh poolside environments.

- Local Sourcing: Buying materials locally can sometimes reduce transportation costs and support local businesses, potentially offering better pricing.

A 100 sq ft deck using pressure-treated lumber for the frame and deck boards might cost $1,000 in materials. Opting for cedar for the deck boards only could raise material costs to $2,000. However, the cedar may last longer and require less frequent sealing, potentially offsetting the higher initial cost over time.

Maintenance for Longevity

Regular maintenance is key to keeping your wood deck looking good and lasting as long as possible. This typically involves cleaning the deck at least once or twice a year to remove dirt, mold, and mildew. Sealing or staining the deck every 1-3 years, depending on the climate and the product used, will protect the wood from UV damage and moisture, preventing it from drying out, cracking, and graying.

Neglecting maintenance can lead to premature decay and structural issues. For a poolside deck, you’ll also want to be mindful of pool chemicals that might spill onto the wood, so prompt cleaning of such spills is advisable. A well-maintained deck not only looks better but also maintains its structural integrity, ensuring safety for years to come.

Key maintenance steps include:

- Annual Cleaning: Use a deck cleaner and a stiff brush to remove surface dirt, grime, and mildew. Rinse thoroughly.

- Sealing or Staining: Apply a quality deck sealer or stain every 1-3 years to protect the wood from the elements. Choose a product designed for your specific wood type.

- Inspect Regularly: Check for loose boards, popped nails, or signs of rot. Address any issues promptly to prevent them from worsening.

- Manage Moisture: Ensure proper drainage around the deck to prevent water from pooling. Keep plants trimmed back from the deck surface.

The cost of basic maintenance, including cleaners and sealants for a 100 sq ft deck, might be $100 to $200 per year. This is significantly less than the cost of repairing or replacing damaged deck boards, which could run into hundreds or even thousands of dollars.

Considering Future Resale Value

A well-built and well-maintained small poolside wood deck can significantly enhance your home’s appeal and resale value. Potential buyers often see decks as valuable additions that extend living space and provide outdoor enjoyment. A clean, attractive deck creates a positive first impression and can make your home stand out in the market.

The return on investment for a deck can be substantial, often recouping a good portion of its cost when you sell your home. However, this depends on the quality of the build, the materials used, and how well it’s maintained. A deck that looks worn or has structural issues can actually detract from your home’s value, making upkeep a crucial investment.

When thinking about resale value:

- Aesthetics Matter: A deck that complements your home’s architecture and landscaping is more attractive to buyers.

- Durability is Key: Buyers want assurance that the deck is built to last and won’t require immediate repairs.

- Safety First: Ensure all railings, stairs, and structural components are sound and meet current safety standards.

- Low Maintenance Appeal: Decks that require minimal ongoing upkeep are often more appealing to busy homeowners.

Studies suggest that homeowners can expect to recoup anywhere from 75% to over 100% of the cost of a deck upon selling their home, depending on the type of deck and the local real estate market. A small, well-executed poolside deck can be a strong selling point.

Frequently Asked Questions

Question: What is the average cost for a 10×10 wood deck?

Answer: For a 10×10 wood deck, you can expect material costs to range from $500 to $6,000+ depending on the wood type, with pressure-treated pine being the most affordable and hardwoods like Ipe being the most expensive. Professional installation can add another $500 to $2,100+, bringing the total estimated cost to anywhere from $1,000 to over $8,100.

Question: Does building a deck near a pool cost more?

Answer: Yes, building a deck near a pool can sometimes cost a bit more. This is because you may need to use more robust, moisture-resistant materials due to humidity and potential chemical exposure. Also, working around existing pool structures might require more specialized labor and careful planning.

Question: Is composite decking cheaper than wood?

Answer: Typically, composite decking has a higher upfront cost than basic wood options like pressure-treated pine. However, over its lifespan, composite decking can be more cost-effective due to its very low maintenance requirements and long durability, avoiding costs associated with staining, sealing, and repairs that wood decks need.

Question: How much does labor typically cost for a small deck?

Answer: Labor costs for a small deck can range from 50% to 70% of the total project cost. For a deck where materials cost $1,000, labor might add another $1,000 to $2,300, depending on the complexity of the design, site conditions, and local labor rates.

Question: Should I get a permit for a small deck?

Answer: It’s always best to check with your local building department. Many areas require permits for deck construction, even for small ones, to ensure they meet safety and building codes. Permit fees are usually a small fraction of the total project cost.

Summary

The total cost for a small poolside wood deck varies widely, from around $1,000 to over $8,000. Key factors include the size, wood type, material quality, and labor rates. Pressure-treated pine is budget-friendly, while hardwoods are premium.

DIY saves on labor, but professional installation offers expertise. Consider site conditions, design complexity, and ongoing maintenance for long-term value and to enhance your home’s appeal.