What Is a Tie Down System in Construction? Your Guide for Automotive and Building Safety

Hey there, friend! So, you’re curious about what is a tie-down system is in construction? I’m really excited to dive into this with you because it’s a topic that’s super interesting and actually connects to us automotive folks more than you might think. I still remember the first time I saw a tie-down system in action at a construction site near my auto shop—it was like watching a giant puzzle come together to keep a building safe.

After years of working on cars, towing vehicles, and chatting with construction buddies who haul materials, I’ve learned how tie-down systems work and why they’re crucial for safety. Whether you’re hauling construction gear, building a garage for your classic car, or just want to understand this system, I’ve got you covered.

Let’s sit down, like we’re hanging out in your driveway with a cold drink, and I’ll break it all down in simple steps. This guide is packed with practical tips for anyone in the USA curious about construction and automotive safety. Ready to learn about tie down systems? Let’s get started!

What Is a Tie-Down System in Construction?

A tie-down system in construction is a set of hardware and straps that anchor a building to its foundation. It keeps structures like houses, garages, or sheds from lifting or sliding during strong winds, earthquakes, or floods. I was amazed when I saw how a few metal brackets and cables could hold a whole house in place!

These systems use things like anchor bolts, hold-downs, straps, and cables to secure walls, roofs, or floors to the ground. In automotive terms, it’s like strapping a car to a trailer to keep it steady during a haul. I’ve seen tie downs on construction sites for new garages, and they’re key to making buildings tough and safe.

Why Are Tie-Down Systems Important?

Buildings face all kinds of forces—wind, quakes, or even heavy snow. Without tie downs, they could tip, slide, or collapse. I learned this when a storm ripped a poorly anchored shed apart near my shop—scary stuff! Tie-down systems act like a seatbelt, keeping the structure in place.

For us, car folks, tie downs are relatable. If you’ve ever hauled a car on a trailer, you know loose straps can spell disaster. In construction, tie downs prevent costly damage and save lives. They’re especially vital in places like California with earthquakes or Florida with hurricanes. I love how they bring peace of mind to builders and homeowners.

How Do Tie-Down Systems Work?

Tie-down systems work by connecting a building’s frame to its foundation. Imagine a house as a box sitting on a concrete slab. Without anchors, it could slide or lift off. I saw this in action when a builder showed me how metal straps tied a garage wall to the foundation—it was rock-solid.

The system uses hardware like bolts embedded in concrete and straps or cables that wrap around beams or walls. These create a “continuous load path,” meaning forces like wind travel from the roof to the ground without breaking anything. I think of it like a tow strap pulling a car; every part needs to be strong to work.

Types of Tie-Down Systems

There are different tie-down systems, and I’ve seen a few on sites. Each suits specific buildings or hazards. Here’s what I’ve learned:

- Anchor Bolts: Metal bolts embedded in the foundation and bolted to the base of walls. I saw these in a new garage build—simple but strong.

- Hold-Downs: Heavy brackets that connect walls to the foundation or other walls. They’re used in tall buildings. I noticed them in a two-story house frame.

- Straps and Ties: Metal straps that wrap around beams or studs. They’re common in wood-frame homes. I used similar straps to secure car parts once.

- Hurricane Clips: Small metal clips that tie roof trusses to walls. They’re big in windy areas. A Florida builder showed me these.

- Cables and Rods: Steel cables or threaded rods that run through the building to anchor it. I saw these in a quake-prone area—they’re beefy!

Each type depends on the building’s design and location. I love how they’re tailored to keep structures safe no matter the challenge.

Components of a Tie-Down System

A tie-down system has key parts, and I’ve gotten to know them well. Here’s what makes it tick:

- Anchors: Bolts or plates set in concrete to grip the foundation. I saw J-bolts in a slab—they’re like roots holding the building.

- Connectors: Brackets, clips, or straps that link wood or steel frames to anchors. I checked out hold-downs at a site—super sturdy.

- Fasteners: Nails, screws, or bolts that secure connectors. I noticed special shear nails in a wall frame.

- Tension Devices: Cables or rods tightened to keep everything snug. A builder let me tug a cable—it was tight as a guitar string!

- Shear Walls: Reinforced walls that resist side-to-side forces. I learned that these work with tie downs for extra strength.

Every part works together like a car’s suspension—each piece has a job to keep the whole system solid.

Where Are Tie-Down Systems Used?

Tie-down systems are everywhere in construction, and I’ve seen them in action. Here’s where they shine:

- Residential Homes: Houses need tie downs to stay put in storms or quakes. I saw straps in a new home’s frame.

- Garages and Sheds: Common for car folks to build storage. I helped a buddy anchor his garage with bolts.

- Mobile Homes: These need heavy tie downs to stay grounded. I noticed cables under a mobile home nearby.

- Commercial Buildings: Warehouses or shops use hold-downs for tall walls. I visited a site with massive brackets.

- High-Risk Areas: Coastal or seismic zones rely on tie downs. A California builder told me they’re mandatory there.

For automotive fans, think about building a shop for your cars—these systems keep it standing through anything.

Tie Down Systems in Automotive Contexts

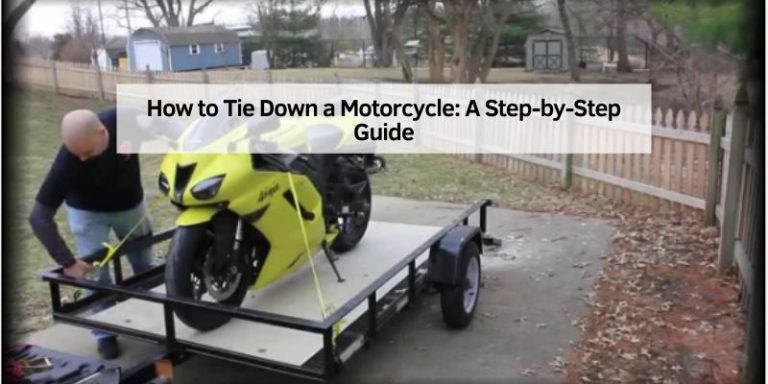

Tie-down systems aren’t just for buildings—they connect to our car world too. I’ve used similar ideas when hauling or towing. Here’s how:

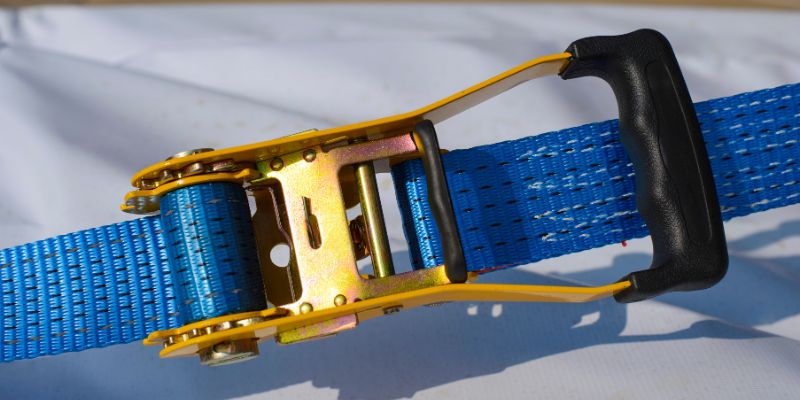

- Hauling Materials: I use ratchet straps to secure lumber or steel for shop builds, like construction tie downs secure beams.

- Towing Vehicles: Car tie downs on trailers are like building anchors, keeping loads steady. I strapped a project car with heavy-duty straps.

- Temporary Structures: At car shows, I’ve seen tie downs anchor tents or awnings, similar to hurricane clips.

- Shop Construction: My buddy’s garage build used tie downs to anchor the frame, protecting his classic cars inside.

The principles are the same—secure something heavy against movement. I love spotting these connections between cars and construction.

Building Codes and Tie Down Systems

Tie downs aren’t optional in most places—they’re required by law. I learned this when helping a friend with his garage permit. Building codes, like the International Residential Code (IRC), set rules for tie downs based on location and hazard.

In the USA, codes vary by state. California demands heavy tie downs for quakes, while Florida focuses on hurricanes. My local code requires anchor bolts every 6 feet for garages. I check with my city’s building department before projects to stay legal. The following code keeps your building safe and avoids fines.

Installing a Tie Down System

Installing tie downs takes planning, and I’ve watched pros do it. Here’s the basic process:

- Plan the System: Engineers design where the anchors and straps go. I saw blueprints for a garage with bolt locations marked.

- Pour Foundation: Set anchor bolts in wet concrete. I watched a crew place J-bolts in a slab.

- Frame the Structure: Build walls and roofs, leaving spots for connectors. I helped nail studs around hold-downs.

- Install Connectors: Bolt or nail straps, clips, or hold-downs to the frame. I saw a builder tighten massive bolts.

- Tension Cables: If using rods, tighten with nuts to remove slack. A pro showed me how to torque them.

- Inspect: Building inspectors check the system. My friend’s garage passed after adding extra straps.

I’m no pro, so I hire contractors for big jobs. But watching them taught me how precise this work is.

Maintaining Tie Down Systems

Tie downs need occasional checks to stay strong. I learned this from a builder friend. Here’s how to maintain them:

- Inspect Annually: Look for rust, loose bolts, or damaged straps. I check my shop’s bolts every spring.

- Tighten Fasteners: Re-torque bolts or nuts if loose. I used a wrench to snug up my garage anchors.

- Clean Metal: Wipe rust with a wire brush and apply anti-rust paint. I painted my hold-downs last year.

- Replace Damaged Parts: Swap out cracked straps or bolts. I replaced a rusty bolt for $5.

- Check Foundation: Look for cracks that weaken anchors. My slab’s solid, but I monitor it.

Maintenance takes an hour a year but keeps your building secure. I make it part of my shop cleanup routine.

Cost of Tie Down Systems

Tie downs vary in price, and I’ve priced them for projects. Here’s the breakdown:

- Anchor Bolts: $1-$5 each. A garage might need 20, so $20-$100.

- Hold-Downs: $10-$50 each. My friend used 10 for $200.

- Straps and Clips: $5-$20 each. A house might need 50, so $250-$1000.

- Cables and Rods: $50-$200 per set. Rare for small builds, but pricey.

- Labor: $500-$2000 for installation, depending on size. My buddy paid $800 for his garage.

Total cost for a garage might be $500-$1500, including labor. I shop at Home Depot or construction suppliers for deals. Big projects need pro quotes.

Common Mistakes to Avoid

I’ve seen tie-down mistakes, so let’s skip these:

- Skipping Codes: Ignoring local rules can fail inspections. I always check my city’s requirements.

- Wrong Hardware: Using weak bolts or straps fails in storms. I buy code-approved parts.

- Poor Installation: Loose bolts or misaligned straps weaken the system. I watch pros to learn.

- No Maintenance: Rust or cracks can sneak up. I check my tie downs yearly to avoid surprises.

- Underestimating Forces: Small tie downs won’t cut it in high-risk areas. I consult engineers for big builds.

I learned from a friend’s shed that collapsed due to weak anchors. Now I double-check everything.

Choosing the Right Tie Down System

Picking a system depends on your project. I’ve helped buddies choose, and here’s what to consider:

- Hazard Type: Wind, quake, or flood? I used hurricane clips for a coastal shed.

- Building Size: Bigger structures need more tie downs. My garage needed 20 bolts.

- Material: Wood frames use straps; steel needs bolts. I matched my wood shop’s needs.

- Budget: Basic bolts are cheap; cables cost more. I balanced cost and safety.

- Local Codes: Follow your area’s rules. I checked my city’s quake standards.

Talk to a structural engineer or contractor. I got advice from a builder friend, and it saved me from guesswork.

Tie Down Systems for DIY Automotive Projects

If you’re building a garage or shop, tie downs are your friend. I helped a buddy anchor his car shop, and here’s how it applies:

- Secure Foundation: Use anchor bolts for concrete slabs. We set 16 bolts for his shop.

- Protect Cars: A tied-down shop won’t collapse on your ride. His Mustang stayed safe.

- Store Gear: Straps keep walls steady for heavy shelves. We hung tools on reinforced walls.

- Expand Later: Strong tie downs support additions. He plans to add a lift area.

- Save Money: DIY with code-approved parts cuts costs. We saved $500 doing it ourselves.

I love how tie downs make my shop a safe haven for my cars. It’s worth the effort for any gearhead.

Here’s a table comparing tie-down components:

| Component | Best For | Pros | Cons | Cost Each |

|---|---|---|---|---|

| Anchor Bolts | Foundations | Cheap, easy | Limited strength | $1-$5 |

| Hold-Downs | Tall walls | Very strong | Pricey | $10-$50 |

| Straps/Clips | Wood frames | Versatile | Needs many | $5-$20 |

| Cables/Rods | Quake zones | High tension | Complex install | $50-$200 |

Advanced Tie Down Systems

For big or risky builds, advanced systems kick in. I’ve seen these on commercial sites:

- Tensioned Rod Systems: Run rods from roof to foundation for max strength. I saw this in a warehouse.

- Base Isolators with Tie Downs: Cushion quakes but anchor tightly. Rare for homes, but cool!

- Hybrid Systems: Mix bolts, straps, and cables. A big shop used this for wind and quakes.

- Retrofit Kits: Add tie downs to old buildings. I helped retrofit a friend’s old garage.

These are overkill for most garages but show how far tie downs can go. I stick to basics for my shop but love learning about advanced stuff.

Why I’m Fascinated by Tie Down Systems

Tie-down systems are like the unsung heroes of construction. They’re simple but keep buildings—and our cars inside—safe from nature’s wrath. I feel like a detective figuring out how bolts and straps work together. They’re perfect for automotive folks building shops or hauling materials, tying our worlds together. My shop’s tie downs give me confidence to park my cars inside, knowing they’re protected.

Wrapping It Up with a Secure Anchor

Hey, buddy, you’re now a tie-down system expert! From anchor bolts to hurricane clips, you’ve got the know-how to keep buildings safe and sound. I remember my first peek at a construction site, and now I grin every time I spot a well-placed hold-down. Head to your next project, whether it’s a garage for your hot rod or hauling materials, and use tie downs with confidence. You’ll keep your builds strong and your automotive dreams safe. So, grab your bolts, check those codes, and build something solid—I’m rooting for you!

FAQ

What is a tie-down system in construction?

It’s hardware like bolts, straps, and cables that anchor a building to its foundation to resist wind or quakes.

Are tie downs required for a ll buildings?

Most need them, but it depends on local codes. My garage needed bolts per my city’s rules.

Can I install tie downs myself?

Yes, for small projects, but follow the codes and plans. I helped a buddy, but hired pros for big jobs.

How much do tie downs cost?

$500-$1500 for a garage, including labor. I spent $600 on my shop’s bolts and straps.

Do tie downs need maintenance?

Yes, check for rust or loose bolts yearly. I inspect my shop’s anchors every spring.

Are tie downs used in mobile homes?

Yes, they’re critical to anchor them to the ground. I saw cables under a mobile home.

How do tie downs help in earthquakes?

They keep the building from sliding or lifting. I used heavy hold-downs in my quake-prone area.