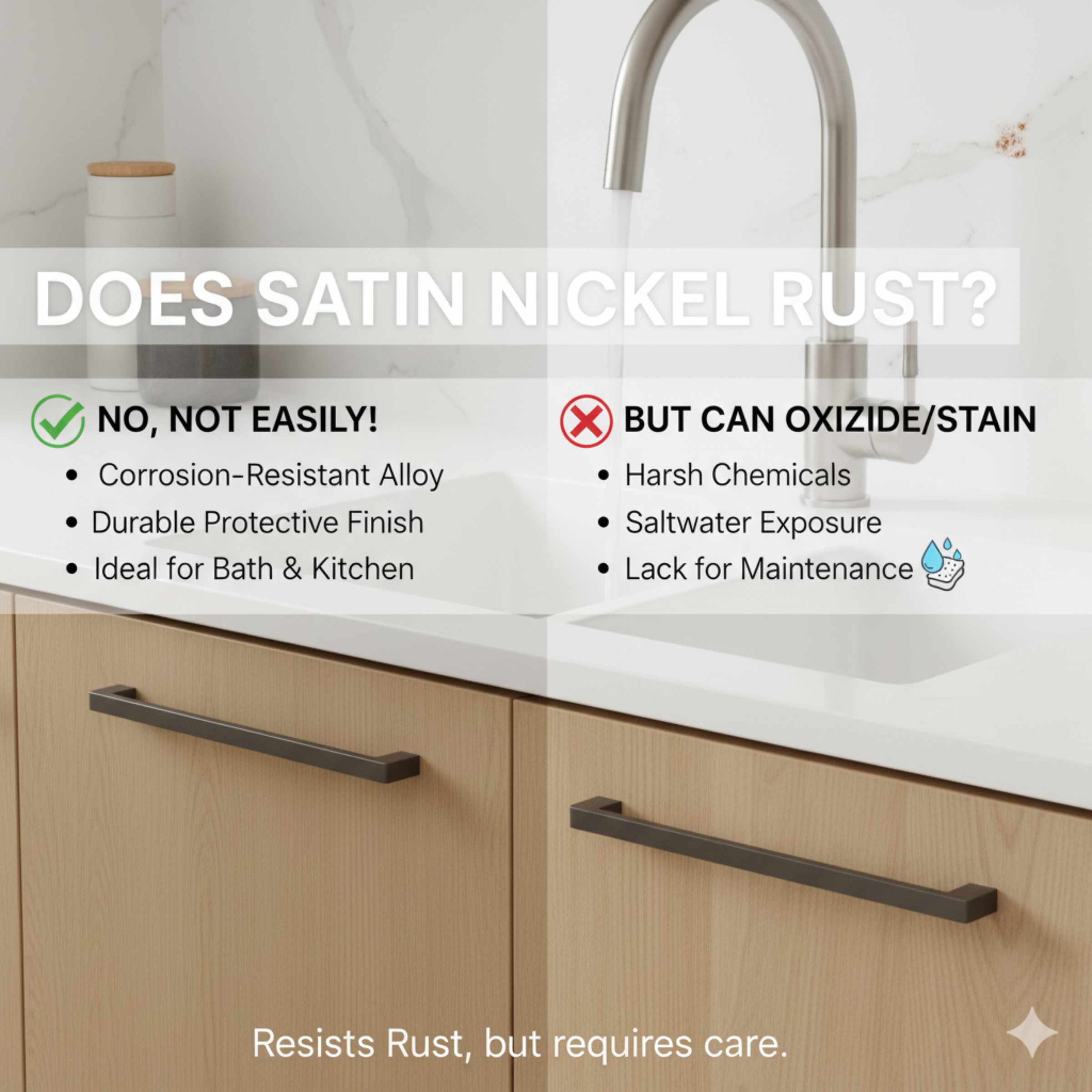

Does Satin Nickel Rust? Essential Care Guide

Quick Summary:

No, satin nickel itself does not rust. True satin nickel finishes are made of nickel alloy and are naturally resistant to corrosion. However, the underlying metal or protective coatings can rust if damaged or exposed to harsh conditions. This guide will show you how to care for your satin nickel to prevent any issues.

Hello there! If you’ve noticed a bit of discoloration or worry about your beautiful satin nickel fixtures, you’re in the right place. Many homeowners wonder, “Does satin nickel rust?” It’s a common question, especially when you’ve invested in stylish hardware for your home, like faucets, door handles, or cabinet pulls. The good news is, the nickel finish itself is quite resilient. Rust is typically a sign that the protective layer has been compromised, exposing the metal underneath. Don’t let this worry you! With a little understanding and some simple care steps, you can keep your satin nickel looking its best for years to come. Let’s dive into how to care for it and what to do if you encounter any issues.

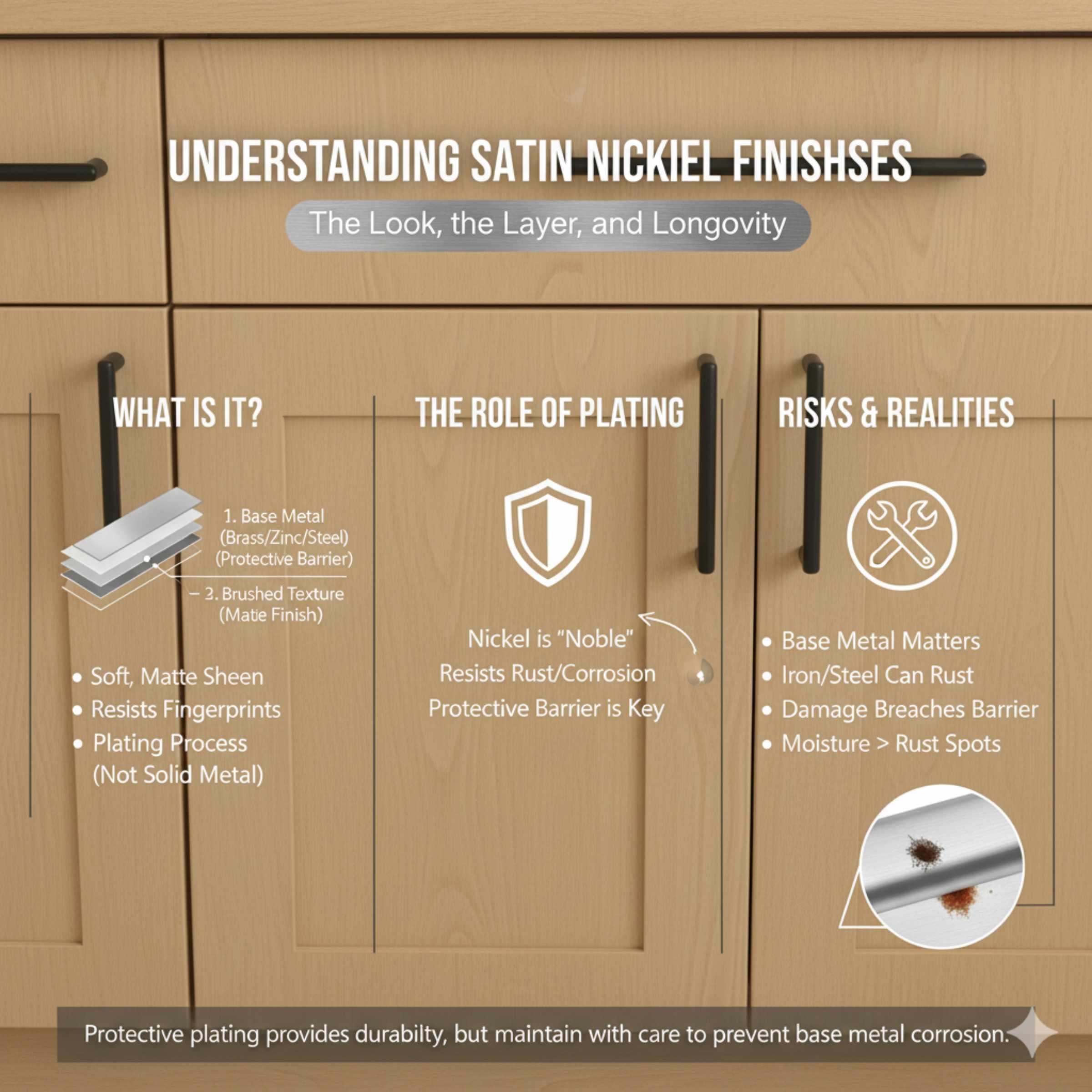

Understanding Satin Nickel Finishes

Satin nickel, often called brushed nickel, is a popular choice for home hardware because it offers a soft, matte sheen that complements many decor styles. Unlike polished chrome or brass, it doesn’t show fingerprints as easily, making it a practical option for busy households. But what exactly is it made of, and why doesn’t it rust on its own?

What is Satin Nickel?

Satin nickel is not usually a solid nickel material. Instead, it’s typically a plating process. A base metal, often brass, zinc, or even steel, is coated with a layer of nickel. The “satin” or “brushed” effect comes from a mechanical process that creates fine lines on the surface, giving it that characteristic matte look. This nickel plating is what provides the resistance to corrosion and tarnishing.

The Role of the Plating

The nickel layer acts as a barrier. Pure nickel is a relatively noble metal, meaning it doesn’t readily react with oxygen or moisture to form rust. This protective plating is key to the longevity and appearance of your hardware. However, this barrier can be breached.

Common Base Metals and Their Risks

The metal underneath the nickel plating is crucial. If the base metal is iron or steel, it has the potential to rust. This is why it’s important to understand that while the nickel finish resists rust, the underlying material might not. Damage to the nickel layer can expose the base metal to moisture, leading to rust spots that can eventually push through the plating.

Does Satin Nickel Rust? The Direct Answer

Let’s get straight to the point: true satin nickel plating does not rust. Rust, chemically speaking, is the oxidation of iron. Since nickel is not iron, it cannot rust. However, what people often perceive as “satin nickel rust” is usually rust forming on the base metal (like steel or iron) that is beneath the nickel plating. This happens when the nickel layer is scratched, chipped, or worn away, exposing the iron-based material to moisture and air.

Think of it like a protective shield. As long as the shield is intact, the underlying material is safe. But if the shield gets a hole, the material underneath can be affected. Therefore, the key to preventing rust on your satin nickel fixtures is to maintain the integrity of the nickel plating.

Factors That Can Lead to Rust or Damage

Even though the nickel itself is rust-proof, several everyday factors can compromise the finish and lead to problems:

- Abrasive Cleaners: Harsh chemicals or abrasive scrubbing pads can scratch or wear down the nickel plating. Over time, this can thin the layer and expose the base metal.

- Excessive Moisture: While nickel is resistant to tarnish, prolonged exposure to standing water, especially in humid environments, can stress the finish. If there are tiny imperfections in the plating, moisture can find its way to the base metal.

- Chemical Exposure: Certain household cleaners, especially those containing strong acids or alkalis (like bleach or ammonia-based cleaners), can damage the nickel surface. Saltwater is also particularly corrosive.

- Physical Damage: Dents, deep scratches, or chips in the finish are direct breaches of the protective nickel layer. These create entry points for moisture and air to reach the underlying metal.

- Age and Wear: Over many years, even with proper care, finishes can naturally wear thin, especially in high-traffic areas.

Essential Satin Nickel Care and Cleaning Guide

Keeping your satin nickel looking great is simpler than you might think. The goal is to clean gently and protect the finish. Here’s how:

Daily Wiping

This is your first line of defense. After each use, or at least once a day, simply wipe down your satin nickel fixtures with a soft, dry microfiber cloth. This removes water spots, fingerprints, and any airborne particles before they can cause damage. This simple habit is incredibly effective.

Regular Cleaning (Weekly or As Needed)

For a more thorough clean, use a mild soap and water solution.

- Mix a Solution: Combine a few drops of mild dish soap (like Dawn) with warm water in a small bowl.

- Dampen Cloth: Dip a soft cloth (microfiber is ideal) into the soapy water and wring it out well so it’s damp, not dripping wet.

- Wipe Down: Gently wipe the satin nickel surface. Avoid scrubbing vigorously.

- Rinse: Use another clean, damp cloth (rinsed with plain water) to wipe away any soap residue.

- Dry Thoroughly: Immediately dry the fixture completely with a separate, clean, dry microfiber cloth. This step is crucial to prevent water spots and potential damage.

Dealing with Tougher Stains

If you encounter stubborn spots or grime that mild soap doesn’t remove, you can try a specialized cleaner formulated for nickel finishes. Always test any new cleaner on an inconspicuous area first.

- Specialized Cleaners: Look for cleaners specifically designed for plated finishes or nickel. Read the product label carefully to ensure it’s safe for satin nickel.

- Vinegar Solution (Use Sparingly): A very dilute solution of white vinegar and water (1 part vinegar to 10 parts water) can help with hard water spots. Apply with a soft cloth, wipe gently, rinse thoroughly with plain water, and dry immediately. Do not let the vinegar solution sit on the surface.

What to AVOID

This is just as important as knowing what to do. Certain products and methods can quickly ruin your satin nickel finish:

- Abrasive Cleaners: Steel wool, scouring pads, abrasive powders (like Comet or Ajax), and even some abrasive sponges can scratch the finish.

- Harsh Chemicals: Bleach, ammonia, oven cleaners, rust removers, and strong acids or alkalis will damage the nickel plating.

- Scrubbing Brushes: Stiff-bristled brushes can scratch the delicate surface.

- Waxes and Polishes (Unless Specified): Some furniture polishes contain ingredients that can build up or react with the finish. Only use products recommended for nickel finishes.

- Leaving Water to Dry: Standing water, especially if your water is hard, can leave mineral deposits that etch the surface over time. Always dry thoroughly.

How to Prevent Rust on Satin Nickel

Prevention is always better than cure. Here are proactive steps to keep your satin nickel looking its best:

Protecting the Finish

- Be Mindful of Scratches: Avoid dragging rough items across hardware. For example, when moving appliances or furniture, cover door handles or take care not to scrape them.

- Regular Inspections: Periodically check your hardware for any signs of chipping, scratching, or unusual discoloration. Early detection makes repairs much easier.

- Dry Immediately After Use: For items like kitchen faucets or bathroom fixtures, a quick wipe with a dry cloth after each use can prevent water spots from becoming permanent issues.

Environmental Considerations

- Humidity Control: In very humid areas, consider using dehumidifiers to reduce moisture in the air, which can benefit all metal finishes.

- Avoid Harsh Environments: Try to keep harsh chemicals away from your hardware. If you’re cleaning near them, protect the fixtures or use very diluted solutions.

What to Do if You See Rust or Discoloration

If you discover rust spots or significant discoloration, don’t panic! It’s usually treatable, especially if caught early. The approach depends on whether the rust is on the plating or the underlying metal.

Step 1: Clean the Area

Start by cleaning the affected area thoroughly with a mild soap and water solution, as described in the regular cleaning section. Dry it completely. Sometimes, what looks like rust is just a stubborn stain or residue.

Step 2: Address Minor Rust Spots

If cleaning doesn’t remove the spots, and you suspect they are from the underlying metal showing through a tiny breach:

- Use a Soft Eraser: For very light rust spots, sometimes a clean pencil eraser can gently lift the rust without damaging the surrounding nickel.

- Mild Abrasive (With Caution): If the eraser doesn’t work, you can try a very mild abrasive. A paste made of baking soda and water applied with a soft cloth might help. Rub very gently in the direction of the “brush” lines. Rinse thoroughly and dry immediately.

- Commercial Rust Remover (Specific Use): If you must use a rust remover, choose one specifically designed for plated surfaces and follow the instructions meticulously. These are often solvent-based and can be harsh. Test in an unseen spot first.

Step 3: Repairing the Finish (If Necessary)

If there’s a noticeable scratch, chip, or significant rust that has eaten into the base metal, the nickel plating may need repair or the item might need replacement.

- Touch-Up Paint/Pens: For minor imperfections where the base metal is exposed, you can find touch-up paint or repair pens in “brushed nickel” or “satin nickel” colors. These are usually a temporary fix but can improve the appearance. Ensure the area is clean and dry before application.

- Professional Refinishing: For valuable or heavily damaged items, professional refinishing services are available. They can strip the old plating and re-plate the item with a new nickel finish.

- Replacement: In many cases, especially with less expensive hardware, replacing the item might be the most cost-effective and aesthetically pleasing solution if the damage is extensive.

Tools and Materials for Satin Nickel Care

You don’t need a lot of specialized tools to keep your satin nickel in top shape. Here’s a simple list of what’s helpful:

| Tool/Material | Purpose | Notes |

|---|---|---|

| Microfiber Cloths | Cleaning, polishing, drying | Soft, non-abrasive, lint-free. Have several on hand. |

| Mild Dish Soap | General cleaning | Gentle, effective for removing grease and grime. |

| Warm Water | Cleaning solution | Helps dissolve soap and lift dirt. |

| Small Bowl | Mixing cleaning solution | For preparing your mild soap and water mixture. |

| White Vinegar (Diluted) | Tackling hard water spots | Use sparingly and rinse thoroughly. |

| Baking Soda | Mild abrasive for stubborn spots | Mix with water to form a paste. Use gently. |

| Pencil Eraser | Removing light rust spots | A clean, soft eraser can be surprisingly effective. |

| Specialized Nickel Cleaner (Optional) | Tougher stains, deep cleaning | Choose products made for plated finishes. Test first. |

| Touch-Up Paint/Repair Pen (Optional) | Minor finish repairs | For covering exposed base metal. |

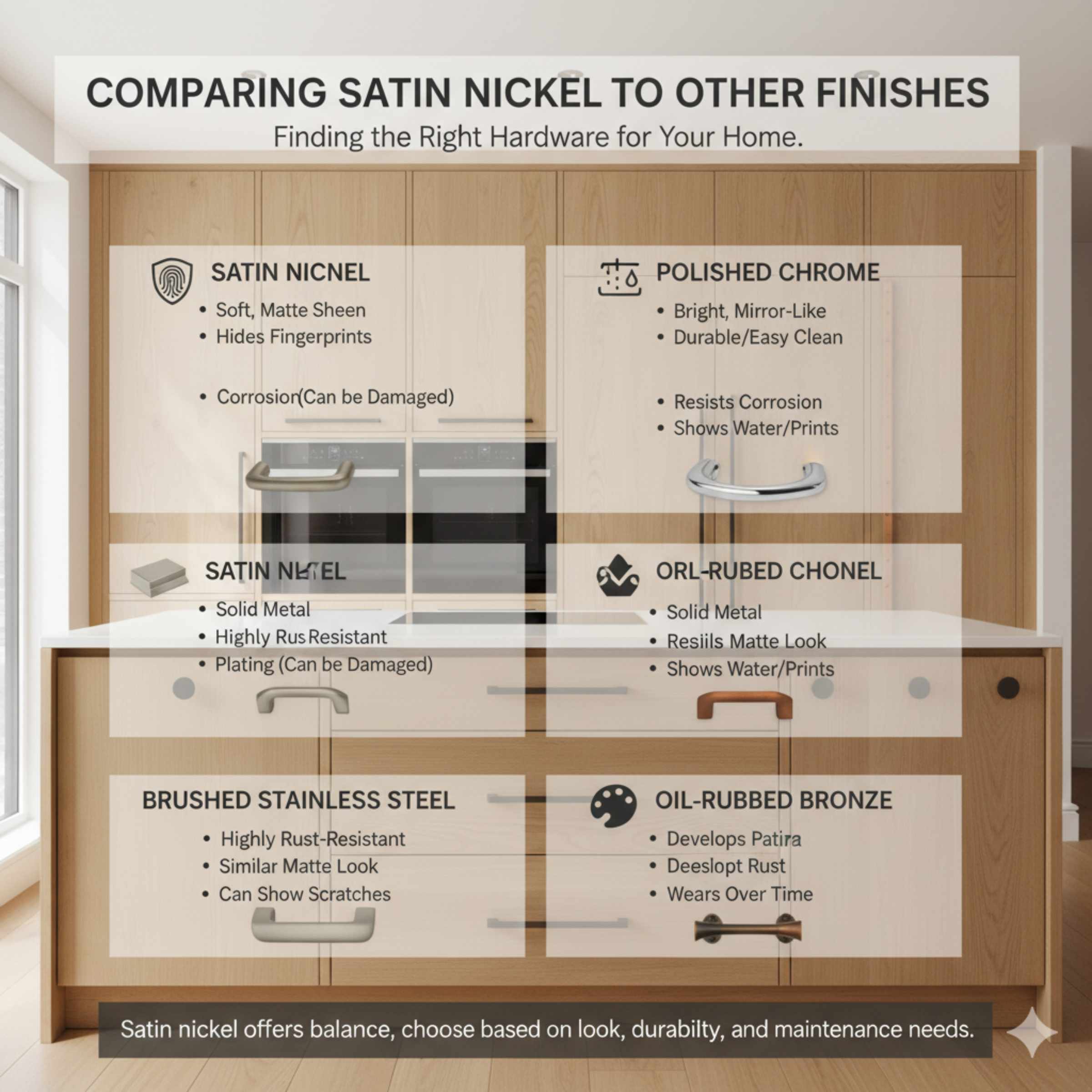

Comparing Satin Nickel to Other Finishes

Understanding how satin nickel compares to other common hardware finishes can help you appreciate its benefits and know its limitations.

Satin Nickel vs Chrome

Chrome is known for its hard, bright, reflective surface. It’s extremely durable and resistant to corrosion and tarnish. Chrome is generally easier to clean and maintain than satin nickel, but it shows fingerprints and water spots very easily. While chrome itself doesn’t rust, like nickel, if the plating is damaged, the base metal could be exposed.

Satin Nickel vs Brushed Stainless Steel

Brushed stainless steel is a solid material, not a plating. It’s highly resistant to rust and corrosion, making it an excellent choice for kitchens and bathrooms. It has a similar matte, brushed look to satin nickel. However, stainless steel can be more expensive and might show scratches more visibly than nickel plating, though it won’t rust from scratches.

Satin Nickel vs Oil-Rubbed Bronze

Oil-rubbed bronze is a finish that mimics aged bronze. It often has a dark, antiqued appearance with coppery undertones. This finish is typically a coating over another metal and is designed to wear over time, revealing lighter tones in high-use areas, which is considered part of its charm. It doesn’t rust but can wear down or change color.

Satin Nickel vs Brass (Unlacquered/Lacquered)

Unlacquered brass will naturally tarnish and develop a patina over time, which many people find attractive. It does not rust. Lacquered brass has a protective coating to prevent tarnishing, but if this lacquer wears off or cracks, the brass underneath can corrode or pit. It won’t rust but can oxidize.

Satin nickel offers a good balance of aesthetic appeal, fingerprint resistance, and decent durability against rust and tarnish, provided the protective plating remains intact. For more information on metal finishes and their properties, you can refer to resources like the Decorative Hardware Association’s guide to finishes, which offers detailed insights into various options available for home hardware.

Frequently Asked Questions (FAQ)

Q1: Can I use stainless steel cleaner on my satin nickel fixtures?

A: It’s generally best to avoid stainless steel cleaners on satin nickel. While some might be mild enough, stainless steel cleaners can sometimes contain abrasives or chemicals that are too harsh for nickel plating. Stick to mild soap and water or cleaners specifically designed for nickel or plated finishes.

Q2: My satin nickel faucet has small brown spots. Is it rust?

A: Those brown spots are likely rust, indicating that the nickel plating has been compromised, and the underlying iron-based metal is oxidizing. Clean the area gently, and if the spots remain, you may need to use a mild rust remover for plated surfaces or consider a touch-up repair.

Q3: How often should I clean my satin nickel hardware?

A: For high-use items like kitchen faucets or bathroom door handles, a quick wipe with a dry microfiber cloth daily is ideal. A more thorough cleaning with mild soap and water can be done weekly or as needed when you notice grime or water spots accumulating.

Q4: Can I polish satin nickel to a shine?

A: Satin nickel is designed to have a matte, brushed finish. Polishing it with standard metal polishes will likely remove the satin effect and could even damage the plating. If you want a high-shine finish, you might consider a polished nickel or chrome fixture instead.

Q5: What if my satin nickel hardware is in a very humid environment, like a steamy bathroom?

A: In humid environments, it’s crucial to ensure thorough drying after use. Wipe down fixtures immediately after showering or bathing to remove condensation. Good ventilation in the bathroom also helps reduce overall moisture levels, protecting all metal finishes.

Q6: Is satin nickel more durable than polished nickel?

A: Both satin and polished nickel are typically plated finishes. The durability against rust is similar, as it depends on the quality of the plating and the base metal. However, satin nickel is generally more forgiving when it comes to showing fingerprints and minor smudges compared to highly reflective polished nickel.

Conclusion

So, to wrap it all up, does satin nickel rust? The nickel finish itself is resistant to rust, but the metal underneath can rust if the plating is damaged. By understanding what satin nickel is, being mindful of what can harm its finish, and following a simple, gentle cleaning routine, you can keep your satin nickel hardware looking beautiful and functional for a long time. Remember, a soft cloth, mild soap, and prompt drying are your best friends in maintaining that lovely satin sheen. With these tips, you can confidently care for your home’s fixtures and enjoy their aesthetic appeal without worry. Happy home maintaining!