What Are Door Handles Made Of: Essential Materials

Door handles are primarily made from durable metals like brass, stainless steel, zinc alloy, and aluminum for strength and longevity, though modern designs also utilize wood, glass, and various durable plastics for aesthetic variety. Choosing the right material depends on your budget, desired look, and the level of wear the handle will endure.

Hey there, DIY friends! Md Meraj here. Standing in the hardware aisle can feel overwhelming, right? You need new door handles, but suddenly you’re faced with choices like “satin nickel” versus “oil-rubbed bronze.” It’s easy to get lost wondering what these things are actually made of and which option will last the longest on your door. Don’t sweat it! Picking the right material is simpler than you think when you know what you’re looking for.

Understanding the core material of your door handle isn’t just about looks; it affects how long it lasts, how much cleaning it needs, and even how much it costs. We are going to break down the most common materials used for door handles today. By the end of this guide, you’ll feel totally confident picking the perfect hardware for any room in your house.

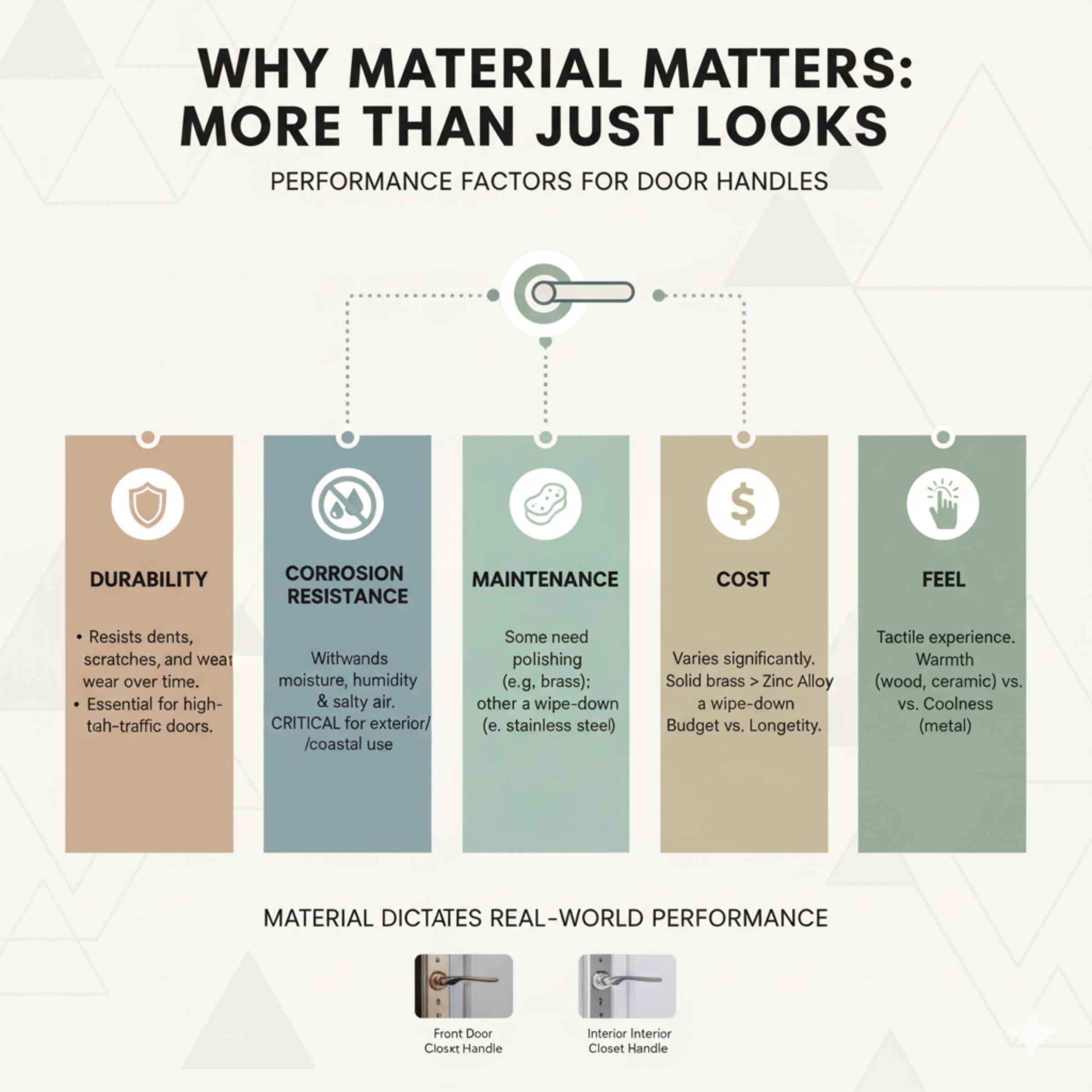

Why Material Matters: More Than Just Looks

When we talk about door handles, we aren’t just talking about aesthetics, although that’s a big part of it! The material dictates the handle’s performance in the real world. Think about the front door versus a closet door. The front door handle takes a beating from weather and constant use, while an interior bedroom handle might only see light use.

Here are the key factors influenced by the material:

- Durability: How well it resists dents, scratches, and breaking over time.

- Corrosion Resistance: How it stands up to moisture, humidity, and salty air (especially important for exterior doors).

- Maintenance: Some materials require regular polishing, while others just need a quick wipe-down.

- Cost: Solid brass will cost more than a zinc alloy handle.

- Feel: The material influences how cool or warm the handle feels in your hand.

The Big Four: Essential Metal Materials for Door Handles

Most high-quality, long-lasting door handles are made from metal. Metals offer the strength needed to withstand the turning and pulling action day after day. Let’s look closely at the heavy hitters you’ll see in every hardware store.

1. Solid Brass: The Classic Choice

Brass is a timeless favorite for door hardware. It’s an alloy made mostly of copper and zinc. It’s known for its beautiful natural luster and incredible longevity. If you see beautiful antique hardware, chances are it’s brass.

Pros and Cons of Brass

Brass handles are tough, but they do require a little upkeep if you want that shiny look.

- Pros: Extremely durable, highly resistant to corrosion, offers a premium, classic look.

- Cons: Generally the most expensive option; solid brass can tarnish (develop a patina) over time, which some people love, but others dislike.

Md Meraj’s Tip: If you love the look but not the maintenance, look for “PVD Brass” finishes. These use advanced coating technology to give you the look of brass without the tarnishing!

2. Stainless Steel: Strength Meets Modernity

Stainless steel is an iron alloy mixed with chromium. This combination creates a surface that actively resists rust and corrosion, making it fantastic for bathrooms, kitchens, and exterior doors where moisture is common. It’s often associated with modern, clean designs.

Stainless Steel Grades

Not all stainless steel is created equal. You will often see grades like 304 or 316. For door hardware, 304 is very common and provides excellent performance for general use.

For coastal areas or extremely harsh environments, 316 stainless steel offers even better resistance to chloride corrosion. Always check the specifications if you live near the ocean!

- Pros: Excellent durability, highly resistant to rust and staining, very low maintenance, great for modern looks.

- Cons: Can sometimes feel colder to the touch than other metals; solid stainless steel can be pricier than basic alloys.

3. Zinc Alloy (Zamak): The Budget Workhorse

Zinc alloy, often referred to by the trade name Zamak (a mix of Zinc, Aluminum, Magnesium, and Copper), is one of the most popular materials for modern, affordable door hardware. It’s easy to cast into complex shapes, which allows manufacturers to offer a huge variety of styles.

While it’s very common, it’s generally not as strong or corrosion-resistant as solid brass or stainless steel. It relies heavily on the quality of its finish (like chrome plating or powder coating) to protect the underlying metal.

- Pros: Very cost-effective, lightweight, easy to manufacture in complex designs, accepts finishes well.

- Cons: Less durable than solid metals; the finish can wear off over time, exposing the softer metal underneath, especially on high-traffic doors.

4. Aluminum: Light and Weather-Resistant

Aluminum is prized for being very lightweight and naturally resistant to rust. It’s often used in commercial settings or for exterior handles where weight is a concern. It can be easily anodized (a process that hardens the surface and adds color).

- Pros: Extremely lightweight, naturally corrosion-resistant, good heat resistance.

- Cons: Softer than brass or steel, making it more prone to scratching or denting if impacted hard.

Finishes vs. Materials: Understanding the Difference

This is where many beginners get confused! The material is what the handle is made of (brass, zinc). The finish is the layer applied on top for color and protection (satin nickel, oil-rubbed bronze).

The finish is critical because it determines the handle’s resistance to fingerprints and wear. Here is a quick comparison of popular finishes often applied over the base metal:

| Finish Name | Base Material Often Used | Durability & Care |

|---|---|---|

| Polished Chrome | Zinc Alloy, Brass | Very durable, easy to clean, shows fingerprints easily. |

| Satin Nickel | Zinc Alloy, Brass | Excellent scratch resistance, hides fingerprints well, very popular. |

| Oil-Rubbed Bronze (ORB) | Brass, Zinc Alloy | A chemical process that darkens the metal; can wear over time, revealing lighter brass underneath. |

| Matte Black | Aluminum, Zinc Alloy | Modern look; durability depends heavily on the powder coating quality. |

Lesser Used, But Interesting, Handle Materials

While metals dominate the market for function, other materials are used either for specific aesthetic purposes or in unique applications. These materials usually need a metal core or mounting hardware for structural integrity.

Porcelain and Ceramic

You often see beautiful porcelain or ceramic used for knobs, especially in older homes or for a cottage/vintage look. These are usually mounted on a metal spindle or base.

- Best For: Low-traffic interior doors, closets, or decorative accents.

- Caution: They are brittle. If dropped or struck hard, they can chip or shatter easily.

Wood

Solid wood handles offer unparalleled warmth and texture. They are typically used in high-end custom homes or rustic designs. Woods like oak, walnut, or cherry are often used because they are dense and durable.

For exterior use, wood handles must be sealed meticulously with marine-grade varnish or oil to prevent warping and water damage. Learn more about exterior wood treatments from resources like university extension services that study wood preservation.

- Best For: Interior doors where a unique, warm feel is desired.

- Caution: Requires regular sealing maintenance, especially near moisture.

Glass and Crystal

Glass handles are purely decorative and often used on bathroom or powder room doors where a touch of elegance is needed. They are almost always attached to a metal rosette or base plate for strength.

Modern tempered glass is quite strong, but like porcelain, it is susceptible to chipping if hit sharply on the edge.

Choosing the Right Handle Material for Your Project

How do you translate this knowledge into a decision for your home? It comes down to location and use. Let’s walk through a few common scenarios to help you decide what material is best.

Scenario 1: The Main Entrance Door (High Security & Weather Exposure)

Your front door handles need to be tough. They face rain, sun, temperature swings, and heavy use.

- Prioritize: Corrosion resistance and structural strength.

- Best Material Choices: Solid Brass (with a good protective lacquer) or 304/316 Stainless Steel.

- Why: These materials won’t degrade quickly when exposed to the elements, ensuring the locking mechanism remains functional for years.

Scenario 2: High-Traffic Interior Doors (Hallways, Kitchens)

These handles are used dozens of times a day, often with dirty or wet hands (from cooking or washing up).

- Prioritize: Durability against abrasion and ease of cleaning.

- Best Material Choices: Stainless Steel or Brass with a durable PVD or Electroplated finish (like Satin Nickel).

- Why: Zinc alloys can work here if the finish is high quality, but stainless steel offers superior long-term scratch resistance against keys and rings.

Scenario 3: Low-Traffic Interior Doors (Guest Rooms, Closets)

These handles don’t see much action and are usually more about matching the decor.

- Prioritize: Aesthetics and budget.

- Best Material Choices: Zinc Alloy, Aluminum, or even Ceramic/Wood accents.

- Why: Since wear and tear are minimal, you can save money by opting for less expensive, aesthetically pleasing materials like a plated zinc alloy handle.

The Impact of Manufacturing Process on Handle Quality

It’s not just what the handle is made of, but how it’s made. A solid piece of metal will always outperform a cheaper alternative, regardless of the finish.

Cast vs. Forged vs. Machined

The manufacturing technique directly impacts the density and strength of the final product:

- Cast: Molten metal is poured into a mold. This is how most inexpensive Zinc Alloy handles are made. It’s fast and cheap, but the resulting metal can have tiny air bubbles (porosity) that weaken the structure.

- Forged: Metal is shaped using intense heat and pressure (hammering or pressing). This process aligns the internal grain structure of the metal, making the handle incredibly dense and strong. Solid brass handles are often forged or cast and then heavily finished.

- Machined: Metal stock (a solid bar) is cut down using computer-controlled tools (CNC). This results in extremely precise, strong handles, often seen in high-end stainless steel or solid brass levers. It is more expensive due to material waste and time.

When shopping, if a handle feels surprisingly light for its size, it’s likely cast zinc alloy. If it feels dense and heavy, you are likely holding solid brass or high-quality stainless steel.

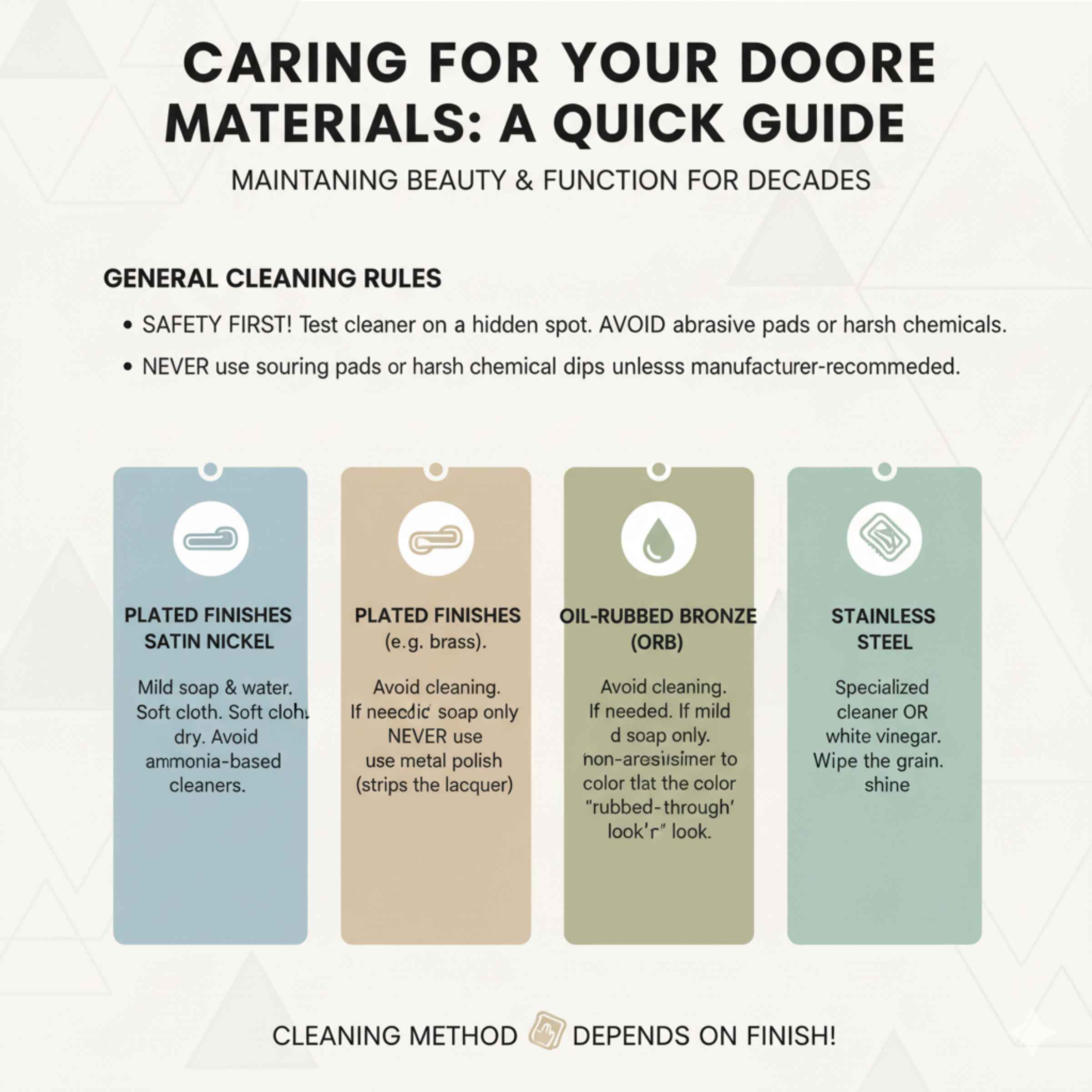

Caring for Your Door Handle Materials: A Quick Guide

Taking care of your hardware ensures it looks great and functions smoothly for decades. The cleaning method depends entirely on the finish, not just the core material.

General Cleaning Rules (Safety First!)

Before cleaning any handle, always test your cleaner on a hidden spot first. Never use abrasive cleaners like scouring pads or harsh chemical dips unless the manufacturer specifically recommends them.

Material-Specific Care Tips

- For Plated Finishes (Chrome, Satin Nickel): Use a soft cloth dampened with mild soap and water. Wipe dry immediately to prevent water spots. Avoid ammonia-based cleaners, which can dull the finish.

- For Lacquered Brass: Avoid cleaning unless necessary. If you must clean it, use only a very mild soap solution. Never use metal polish, as it will strip off the protective lacquer coating.

- For Oil-Rubbed Bronze (ORB): ORB is designed to wear. If you want to maintain the dark color, use specialty wax or non-abrasive cleaners. If you like the rubbed-through look, just clean with mild soap.

- For Stainless Steel: Use specialized stainless steel cleaner or a cloth lightly dampened with white vinegar for a streak-free shine. Always wipe with the grain of the steel.

FAQ: Beginner Questions About Door Handle Materials

Q1: Is it okay to mix different metal finishes on my doors?

A: Absolutely! Mixing finishes like matte black on the exterior and satin nickel on the interior is a popular design choice. Just try to keep the finishes consistent within a single room or space for a cohesive look.

Q2: Which material is the best for resisting fingerprints?

A: Satin Nickel and Oil-Rubbed Bronze finishes are generally the best at hiding fingerprints because their texture diffuses light. Polished Chrome and Polished Brass show prints very easily.

Q3: How can I tell if my old handle is solid brass or just brass-plated?

A: If the handle is very old and heavy, it’s likely solid. If you see any scratches or chips where a different, often duller, metal color shows through the gold, it is plated. You can also use a magnet—solid brass is not magnetic, but some base metals used in plating might have a slight attraction.

Q4: Are plastic door handles safe or durable?

A: Plastic handles are usually reserved for very temporary setups or specialized low-use applications (like utility closets). While they are cheap, they lack the structural integrity needed for daily turning and pulling and can crack easily under stress.

Q5: Do I need special hardware for a bathroom door handle?

A: Yes! Bathrooms are high-humidity areas. You need a material highly resistant to rust. Stainless steel or solid brass with a high-quality finish (like PVD) is best to prevent the handle mechanism from seizing up due to moisture.

Q6: What does “living finish” mean when buying hardware?

A: A living finish, like traditional unlacquered brass or ORB, is designed to change over time based on how you use it and what it’s exposed to. It develops a unique patina—it ages naturally rather than staying static. This is great for a rustic look but not for someone who wants a consistent shine.

Conclusion: Confidence in Your Hardware Choice

See? You’ve got this! Deciding what your door handles are made of stops being a guessing game and starts being a smart decision based on function and environment. Remember the core principle: Exterior doors and high-use areas demand high-durability materials like stainless steel or solid, well-finished brass.

For lower-traffic interior doors, you have the freedom to prioritize style and budget, often leaning toward durable zinc alloys with excellent finishes. By focusing on the material’s inherent strength—whether it’s the rust-fighting power of stainless steel or the dense quality of forged brass—you ensure your hardware will stand up to years of opening and closing. Happy upgrading, and remember, every confident choice you make on your DIY journey builds your skills for the next project!