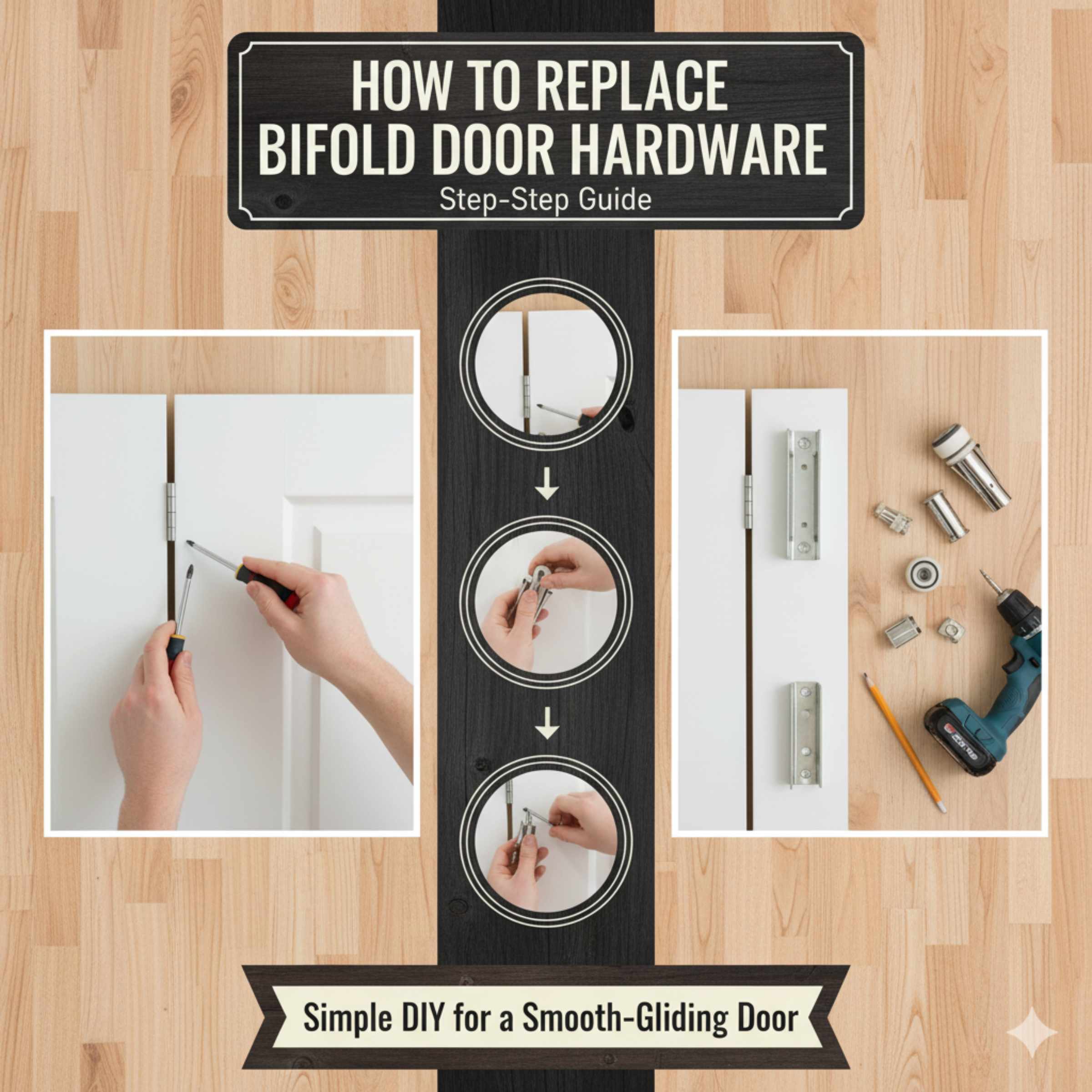

How To Replace Bifold Door Hardware: Proven Essential Fix

Replacing bifold door hardware is a straightforward DIY fix. You can easily swap out old, squeaky hinges, rollers, or pivot rods by identifying the correct replacement parts, carefully removing the old hardware using basic tools, and installing the new components following the manufacturer’s guide. This project restores smooth operation quickly.

Bifold doors are fantastic for saving space, but when they start sticking, dragging, or falling off the track, it’s incredibly annoying. You don’t need to call a professional handyman for every little squeak or jam. Most common bifold door problems are caused by worn-out hardware—the little hinges, pivots, and rollers that do all the heavy lifting. Fixing this yourself is easier than you think! We are going to walk through every step, from figuring out what parts you need to making your door glide like new again. Get ready to gain some serious DIY confidence as we tackle how to replace bifold door hardware the right way.

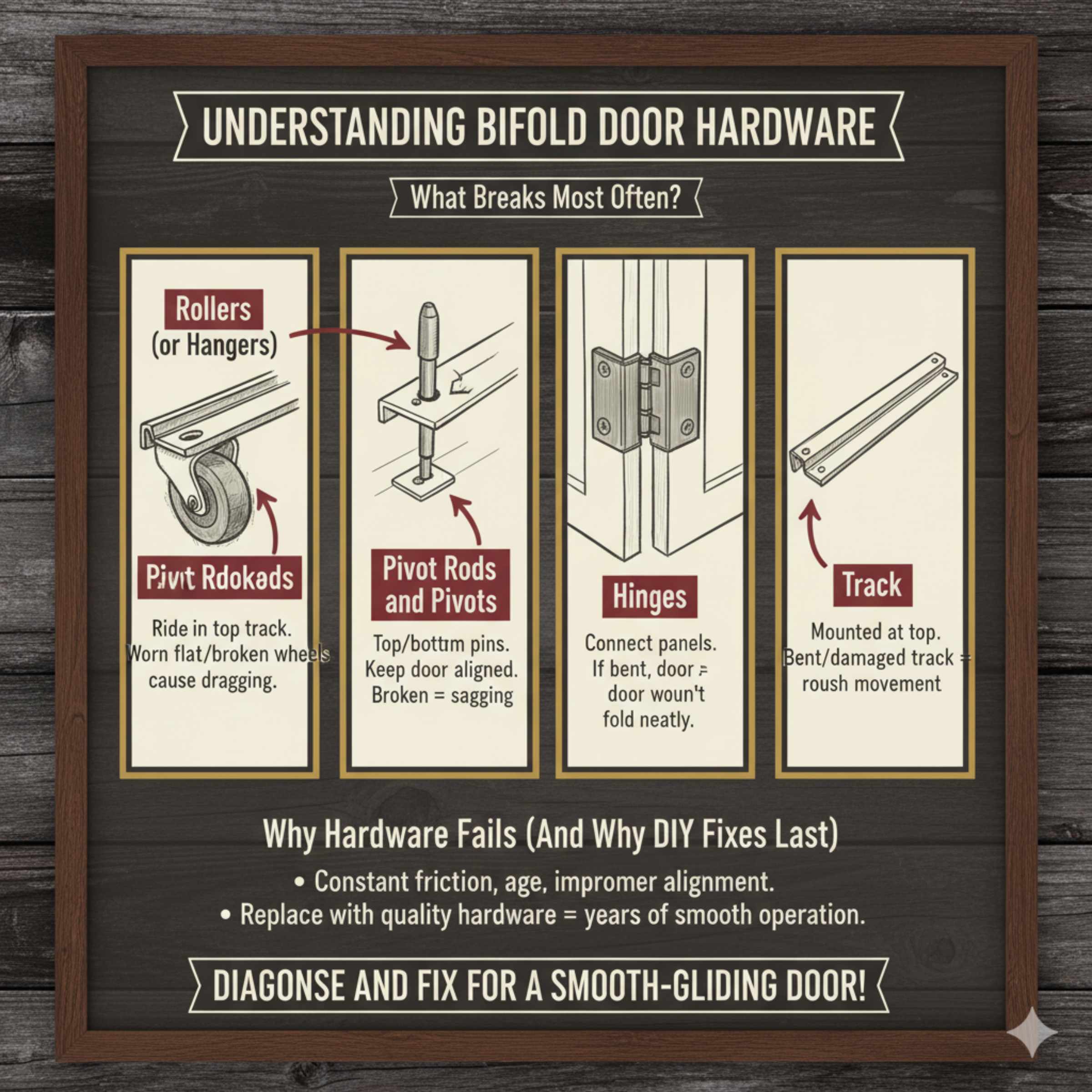

Understanding Bifold Door Hardware: What Breaks Most Often?

Before we start taking things apart, let’s look at the main components of a standard bifold door system. Knowing what these parts do helps you diagnose the problem correctly. Usually, only one or two pieces need replacing, not the whole door!

The Key Components You Might Need to Replace

Bifold doors use a track system mounted at the top of the door frame. The door panels themselves are connected by pivot pins and hinge assemblies.

- Rollers (or Hangers): These sit at the top of the door panels and ride inside the top track. If these are worn flat or have broken wheels, the door will drag or jump off the track.

- Pivot Rods and Pivots: These are the pins, usually one at the top and one at the bottom, that keep the door aligned and allow it to swing open and closed. If the bottom pivot breaks, the door often sags or falls out of the bottom guide.

- Hinges: These connect the two panels of the bifold door together. If they bend or break, the door won’t fold neatly.

- Track: While less common to replace, if the metal track itself is bent or severely damaged, it must be replaced to ensure smooth movement.

Why Hardware Fails (And Why DIY Fixes Last)

Hardware typically fails due to constant friction, age, or improper alignment during installation. Plastic components can crack, and metal parts can wear down. When you replace these parts with quality new hardware, you are resetting the system for years of smooth operation. For reference on proper door installation standards, you can often find helpful guidelines published by organizations like the International Residential Code (IRC), which emphasizes secure fastening for all door systems.

Step 1: Diagnosing the Problem and Gathering Your Tools

We need to know exactly what is broken before we buy anything. A door that drags might need new rollers, while a door that won’t stay closed might need a new bottom pivot or a closer mechanism adjustment.

Identifying the Problem Symptoms

Watch your door closely as you open and close it. Where does it bind?

| Symptom | Most Likely Hardware Issue |

|---|---|

| Door drags on the floor or jamb. | Worn bottom pivot or bent top roller assembly. |

| Door falls out of the track. | Broken top roller or damaged top track. |

| Door won’t fold or is crooked. | Damaged hinges connecting the two panels. |

| Door won’t stay shut. | Worn or missing magnetic catch or roller pin. |

Essential Tools for Replacing Bifold Hardware

Don’t worry; you won’t need a massive workshop setup for this job. Most of these tools are probably already in your toolbox. Safety first—always wear your safety glasses!

- Safety Glasses: Protect your eyes from falling dust or springs.

- Screwdriver Set: Both Phillips and flathead, as hardware uses various screw types. A cordless drill with clutch settings is faster, but be careful not to overtighten.

- Putty Knife or Thin Pry Bar: Useful for gently lifting the door out of the track.

- Tape Measure: Essential for matching new hardware dimensions.

- Pliers (Needle-Nose): Helpful for manipulating small pivot pins or springs.

- Replacement Hardware Kit: Ensure you have the specific parts needed (rollers, pivots, hinges).

Step 2: Purchasing the Right Replacement Hardware

This is the most critical step for long-term success. You cannot just buy generic hardware; it must match your existing door style and manufacturer, if possible. If you don’t know the door brand, take your old hardware to the hardware store.

Matching the Hardware

Hardware dimensions are crucial. A difference of just an eighth of an inch can mean the new part won’t fit the track or pivot hole correctly.

- Measure Everything: Measure the diameter of the roller wheel, the length of the pivot rod, and the distance between screw holes on hinges.

- Take Photos: Photograph the old hardware from multiple angles before removing it. This is your best reference guide.

- Visit a Specialty Store: While big box stores carry common sizes, sometimes visiting a dedicated door/window hardware supplier or a well-stocked local hardware store yields better results for older or unusual hardware sets.

Pro Tip: If you are replacing rollers, consider buying a full set of new rollers, hinges, and pivots together as a complete bifold repair kit. This ensures everything is brand new and matches in terms of wear.

Step 3: Safely Removing the Bifold Door Panel

We need to take the door panel—or at least the door panels you are working on—out of the frame so you can access the hardware comfortably on a workbench or the floor. This is usually the part that intimidates beginners the most, but it’s straightforward if done in the correct order.

Removing the Door from the Top Track

The top track supports the door’s weight via the rollers. We lift and tilt to release them.

- Open the Door Fully: Open the bifold door completely, pushing it toward the hinge side as far as it will go. This gives you the most slack.

- Lift and Tilt: Grasp the top edge of the door panel that holds the roller. Lift the panel straight up toward the track. Once the roller is slightly disengaged from the track slot, tilt the bottom of the door away from the door frame.

- Clear the Track: Gently lower the door panel slightly until the roller assembly clears the track opening. You might need a second person to hold the door steady while you work the roller free.

- Repeat (If Necessary): If you are working on the second panel, repeat this process for that panel.

Safety Note: Bifold doors can sometimes be heavy, especially wooden ones. Always support the door weight securely before attempting to lift it out of the track. Never let the door hang freely from just one side.

Releasing the Bottom Pivot

Once the top is free, the bottom pivot pin usually just lifts out of its socket, or you might need to unscrew a retaining bracket.

- Locate the bottom pivot pin, usually found near the hinge side of the door, sitting in a small hole or guide bracket on the floor or door jamb.

- If it’s a spring-loaded type, you might need to depress the spring slightly with a screwdriver while pulling the pin upward.

- If it’s held by a bracket, remove the screws holding the bracket to the floor or frame. Keep these screws safe!

Step 4: Replacing the Worn Hardware Components

Now that the door is accessible, we can swap out the old, failing parts for your shiny new ones.

How to Replace Bifold Door Rollers (Hangers)

Rollers are typically located inside a housing unit attached to the top edge of the door panel.

- Locate Screws: Identify the screws holding the roller assembly housing to the top of the door stile (the vertical edge).

- Remove Old Hardware: Carefully remove these screws. Be ready to support the roller assembly as it comes free, as it might be under slight tension.

- Install New Roller: Place the new roller assembly into the space. Ensure the wheel is oriented correctly to sit inside the track groove.

- Secure Firmly: Reinstall and tighten the screws. Do not overtighten, especially if attaching to hollow-core doors, as you can strip the wood or particle board.

How to Replace Bifold Door Pivots and Guides

Pivots are the alignment pins. If the top pivot is integrated into the roller assembly, you’ve already replaced it. If you have a separate bottom pivot:

- Remove the old bottom pivot assembly by unscrewing its retaining bracket or pulling the pin out if it was spring-loaded.

- Check the hole where the pivot sits. If the hole in the door bottom is stripped or enlarged, you may need to use wood filler or a slightly larger screw/anchor to ensure the new pivot sits snugly.

- Install the new pivot pin assembly, ensuring it is oriented correctly according to the new part’s instructions.

Replacing Bifold Door Hinges

The hinges connect the two door leaves (panels) together. These often require a screwdriver rather than a drill to avoid damaging the thin wood or composite material.

- Have a helper hold the door panels together, or prop the door panel you are working on securely against a stable object.

- Unscrew the old hinge from the edge of the panel.

- Align the new hinge perfectly with the existing screw holes. Sometimes, new hinges might have slightly different hole patterns. If so, you’ll need to drill small pilot holes for the new screws, ensuring you don’t drill through the face of the door panel.

- Screw the new hinge in place, ensuring the connection between the two panels allows for smooth folding action.

Step 5: Reinstalling the Door and Testing the Glide

Putting the door back in the track requires reversing the removal process, but with careful alignment.

Setting the Door Back into the Top Track

This step requires coordination. It’s easier if you have someone to help hold the door steady.

- Prepare the Bottom: Ensure the bottom pivot pin is ready in its floor/jamb socket or bracket.

- Align the Top Rollers: Hold the door panel upright. Lift the top edge slightly toward the track. Insert the new roller assembly wheel into the track groove.

- Engage the Track: While holding the roller in the track, tilt the door panel until it drops down enough for the bottom pivot to align with its hole or guide.

- Seat the Pivot: Push the door down gently until the bottom pivot seats securely into its guide.

Testing and Adjusting the Alignment

Once the door is hanging, open and close it several times. It should move smoothly without catching.

If the door still drags or rubs the frame, you need to adjust the height. Most modern top roller assemblies have an adjustment screw built right into the hanger bracket. Consult your specific hardware instructions, but generally:

- Turning the adjustment screw clockwise usually raises the door panel slightly.

- Turning it counter-clockwise lowers the door panel slightly.

Adjust in small increments (half a turn at a time) until the door hangs perfectly level and clears the floor and jambs.

Maintenance Tips for Long-Lasting Bifold Hardware

Now that you’ve mastered how to replace bifold door hardware, keeping it running smoothly is easy. A little preventative care goes a long way!

Lubrication is Key

Metal-on-metal or plastic-on-metal contact needs lubrication to prevent premature wear. This is especially true for the rollers and pivots.

| Hardware Part | Recommended Lubricant | Frequency |

|---|---|---|

| Top Track & Rollers | Dry Silicone Spray Lubricant (Avoid greasy oils) | Every 6–12 months |

| Pivot Pins | White Lithium Grease or Dry Lube | Annually |

| Hinges | Light machine oil or specialized hinge lubricant | As needed (if squeaking) |

Why Dry Lube? Greasy oils (like standard WD-40, though great for initial cleaning) attract dust and dirt, which builds up in the track and actually makes the door stick worse over time. Dry silicone spray dries clean, providing lubrication without the mess. You can research the benefits of dry lubricants versus wet lubricants for moving parts on sites dedicated to home maintenance.

Keep the Track Clear

The track is the highway for your rollers. If it’s full of paint chips, dust bunnies, or debris, your new hardware won’t work well.

- Use a vacuum cleaner hose attachment to suck out debris from the top track.

- If debris is stuck, gently scrape it out using a plastic putty knife or an old credit card. Avoid metal tools that might scratch or bend the track.

- Check the track alignment. If you notice it is bent or warped, you may need to replace the track itself, which is a slightly more involved process but still DIY-friendly.

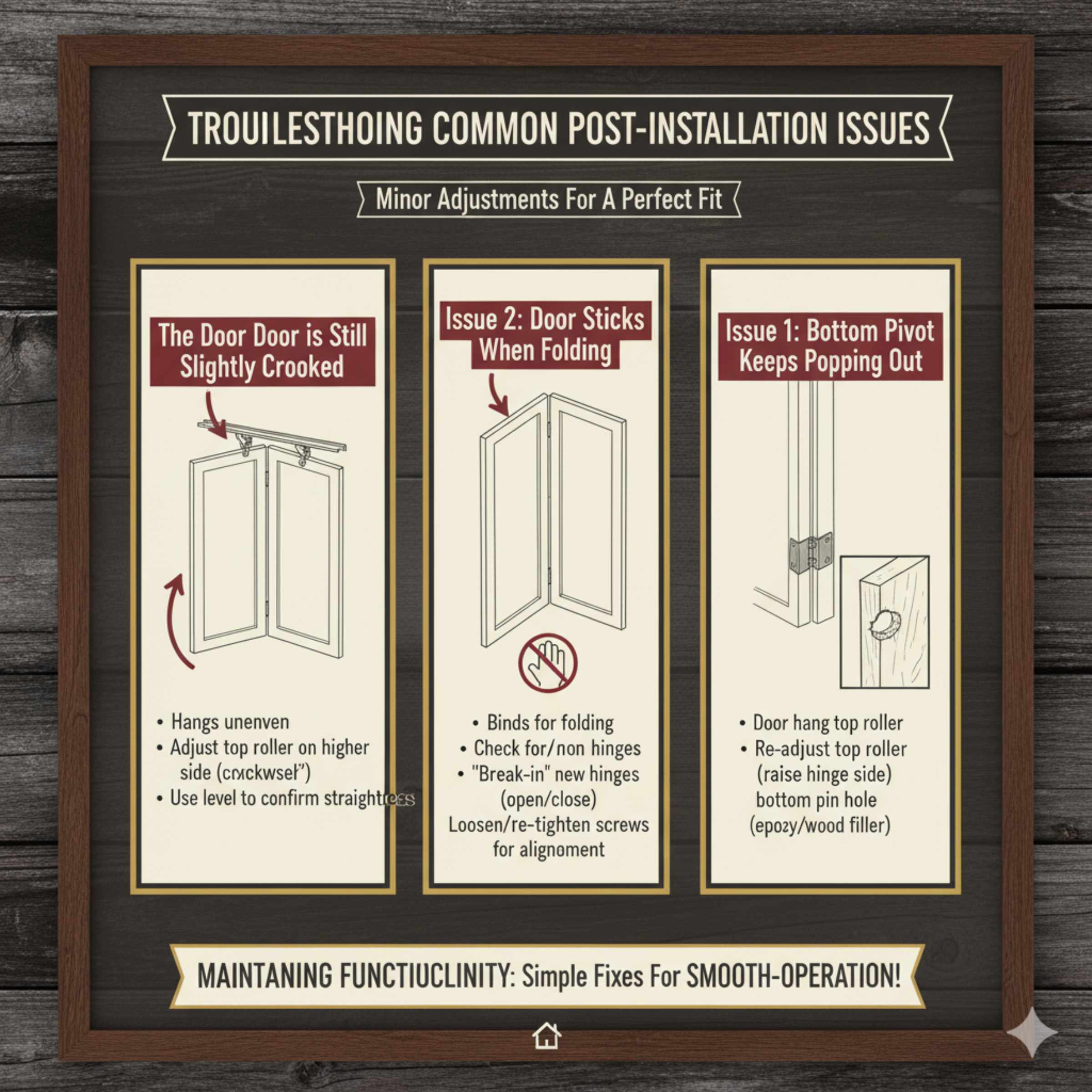

Troubleshooting Common Post-Installation Issues

Even after a perfect replacement, sometimes things don’t line up immediately. Don’t panic; these are usually minor adjustments.

Issue 1: The Door is Still Slightly Crooked

If the door hangs unevenly from side to side, the adjustment is almost always in the top roller assembly on the higher side.

- Identify the side that is too low.

- Adjust the corresponding roller assembly (usually by turning the adjustment screw clockwise) until the door hangs level. Use a small level placed across the bottom edge of the door panel to confirm it is straight.

Issue 2: The Door Sticks When Folding

If the door opens fine but binds when it folds in half, the issue is likely the hinges connecting the panels.

- Check the new hinges. Are they installed flush?

- If the hinges are new, they might need “breaking in.” Open and close the door repeatedly, focusing on the folding action.

- If the binding continues, you may need to slightly loosen the hinge screws, wiggle the panels into perfect alignment, and retighten them.

Issue 3: The Bottom Pivot Keeps Popping Out

This means the door is not hanging straight, putting lateral (sideways) pressure on the bottom pin, causing it to jump its guide.

- Re-check the top roller adjustment. Raising the door slightly on the hinge side can often correct the angle enough to keep the bottom pin seated.

- Ensure the hole in the bottom of the door panel itself isn’t too large for the pivot pin. If the hole is worn out, you must repair the wood using epoxy or wood filler before re-inserting the pivot.

Frequently Asked Questions (FAQ) About Bifold Hardware Replacement

Q1: Do I need to remove the entire door track to replace a roller?

A: Generally, no. For most standard systems, you only need to remove the door panel itself. Once the panel is out, you can access the roller housing from the top edge of the door and remove it by unscrewing the housing.

Q2: Can I mix and match hardware brands when replacing parts?

A: It’s best practice to stick to one brand or use a complete replacement kit. Different manufacturers use proprietary sizes for pivot diameters and track depths. Mixing parts often leads to alignment issues and premature failure.

Q3: How do I know if I need to replace the track itself?

A: You should replace the track if it is visibly bent, severely dented, or if the rollers jump out repeatedly even after adjusting the roller height. A bent track physically prevents smooth operation regardless of how good your rollers are.

Q4: What is the easiest way to remove a stubborn pivot pin?

A: If the pin is stuck, try applying a small amount of penetrating oil (like Liquid Wrench) around the base of the pin. Let it sit for 15 minutes. Then, use needle-nose pliers to gently wiggle the pin side-to-side while pulling upward. Never force it with a hammer, as you could damage the frame.

Q5: Is it cheaper to repair the hardware or replace the whole bifold door?

A: Repairing the hardware is almost always significantly cheaper. A full set of replacement hardware usually costs between $20 and $50, whereas a new door unit can cost several hundred dollars. Hardware replacement is a great way to extend the life of your existing door!

Q6: How much adjustment range do the top rollers usually offer?

A: Most standard bifold roller assemblies provide about 3/8 inch to 1/2 inch of vertical adjustment range. This is usually enough to level the door unless the door frame itself is severely racked or out of square.

Conclusion: Enjoying Smooth, Reliable Doors

See? You’ve successfully learned how to replace bifold door hardware! It’s a project that looks complicated from the outside but breaks down into simple, manageable steps when you tackle it systematically. By correctly diagnosing the issue, carefully removing the door, selecting the right replacement parts, and taking the time to adjust the alignment upon reinstallation, you’ve saved yourself time and money.

Remember, DIY success comes from preparation. Keep those old parts handy for reference, use the right lubricant next time, and always adjust slowly. Your bifold doors should now glide open and closed with satisfying smoothness. Feel proud of the skills you’ve built today—you’ve handled a tricky home repair like a seasoned pro. Happy DIY-ing!